This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

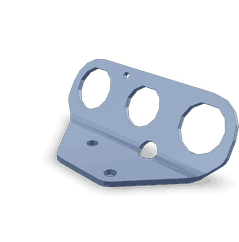

The 2891507 Electrical Connector Bracket by Cummins is designed to enhance the functionality and reliability of heavy-duty truck electrical systems. This part plays a significant role in securing and organizing electrical connections, ensuring efficient and safe operation of the electrical system.

Basic Concepts of Electrical Connector Brackets

An Electrical Connector Bracket serves as a mounting and organizing solution for electrical connectors and wires within a vehicle’s electrical system. Its primary function is to hold connectors in place, protect them from physical damage, and facilitate easier access for maintenance and repairs. By providing a structured environment for electrical connections, these brackets help maintain the integrity and performance of the electrical system 1.

Purpose of the 2891507 Electrical Connector Bracket

This Cummins part is specifically designed to secure and organize electrical connections in heavy-duty trucks. It ensures that connectors remain firmly in place, reducing the risk of disconnections or damage. This bracket helps maintain the organization of wires, which is vital for the efficient operation of the truck’s electrical components.

Key Features

The 2891507 features a robust construction, typically made from durable materials to withstand the harsh conditions encountered in heavy-duty truck environments. Its design includes elements that allow for secure attachment of connectors and wires, ensuring stability and protection. Unique attributes may include corrosion-resistant coatings and ergonomic design for ease of installation and maintenance.

Benefits

This part offers several advantages. It contributes to improved reliability of the electrical system by securing connections and protecting them from environmental factors. The organized layout facilitated by the bracket simplifies maintenance tasks, potentially reducing repair times. Additionally, the durability of the bracket ensures long-term performance, minimizing the need for frequent replacements.

Installation Process

Installing the 2891507 involves several steps to ensure a secure and effective setup. Preparatory steps include identifying the correct location for the bracket and ensuring the area is clean and free from obstructions. Tools required may include a wrench for tightening bolts and a screwdriver for securing the bracket. Best practices involve following the manufacturer’s instructions closely, ensuring all connections are tight and secure, and verifying that the bracket does not interfere with other components.

Troubleshooting Common Issues

Typical problems with Electrical Connector Brackets may include loose connections or corrosion. Diagnosing these issues involves inspecting the bracket and connections for signs of wear or damage. Resolving these issues may require tightening connections, cleaning affected areas, or replacing damaged components. Regular inspections can help identify potential problems before they lead to more significant issues 2.

Maintenance Tips

To ensure the longevity and optimal performance of the 2891507, regular maintenance practices are recommended. This includes routine inspections to check for signs of wear, corrosion, or loose connections. Cleaning the bracket and surrounding areas can prevent the buildup of dirt and debris that may affect performance. Following these maintenance tips can help maintain the efficiency and reliability of the truck’s electrical system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the heavy-duty truck industry for producing reliable and high-performance components. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications.

Role of Part 2891507 Electrical Connector Bracket in Engine Systems

The 2891507 is an integral component in the assembly and organization of various electrical systems within engine setups. It provides a secure mounting point for electrical connectors, ensuring that they remain firmly in place despite the vibrations and movements inherent in engine operations.

Integration with Harness

When interfacing with the harness, this part plays a significant role in maintaining the structural integrity of the electrical connections. It supports the harness by preventing undue stress on the wires, which could otherwise lead to fraying or disconnection. This bracket ensures that the harness is routed efficiently, minimizing the risk of interference with other engine components.

Function with Electronic Control Module Wiring

In conjunction with the Electronic Control Module (ECM) wiring, the 2891507 helps in organizing the myriad of connections that the ECM requires. By providing a stable platform for these connections, it aids in the efficient transmission of data and power between the ECM and various sensors or actuators. This organization is essential for the ECM to function optimally, receiving accurate data and sending precise commands.

Contribution to Wiring Harness Setup

The Wiring Harness benefits significantly from the 2891507 by ensuring that all connections are kept tidy and secure. This bracket assists in managing the spatial constraints often found in engine compartments, allowing the Wiring Harness to be positioned without obstruction. It also protects the Wiring Harness from physical damage, such as abrasion or impact, which could compromise the electrical integrity of the system.

Conclusion

In summary, the 2891507 Electrical Connector Bracket is a key component in the electrical architecture of engine systems, facilitating the secure and efficient operation of the Harness, ECM Wiring, and Wiring Harness. Its robust construction, ease of installation, and maintenance benefits make it an essential part for ensuring the reliability and performance of heavy-duty truck electrical systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.