This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Air Crossover Connector, identified by part number 4967153, is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industry. This connector plays a significant role in the air systems of heavy-duty trucks, facilitating the efficient distribution of compressed air throughout the vehicle.

Function and Operation

The Air Crossover Connector operates within the truck’s air system by linking various air lines, allowing for the distribution of compressed air to different components such as brakes, suspension systems, and other pneumatic devices. It ensures that air is evenly distributed, which is vital for the consistent performance of these systems. The connector is designed to handle high-pressure air, ensuring that the air system functions smoothly under various operating conditions 3.

Key Features

The Air Crossover Connector is constructed from durable materials, typically including high-grade metals and robust polymers, which contribute to its longevity and reliability. It features secure connection points, often utilizing threaded or quick-connect fittings, to ensure a tight seal and prevent air leaks. The design may also incorporate features such as built-in filters to trap contaminants, enhancing the overall efficiency of the air system 4.

Benefits

One of the primary advantages of the Air Crossover Connector is its role in improving the efficiency of air distribution within the truck. By ensuring a consistent and reliable flow of compressed air, it contributes to the optimal performance of pneumatic systems. Additionally, its durable construction and reliable design enhance the overall reliability of the truck’s air system, reducing the likelihood of unexpected failures 2.

Installation and Compatibility

Proper installation of the Air Crossover Connector is crucial for its effective operation. It should be installed according to the manufacturer’s guidelines, ensuring that all connections are secure and that the connector is compatible with the specific truck model and air system. Specific requirements or precautions may include ensuring the system is depressurized before installation and verifying that all fittings are correctly aligned and tightened to the recommended torque specifications 1.

Maintenance and Troubleshooting

Routine maintenance of the Air Crossover Connector involves regular inspection for signs of wear or damage, such as cracks or leaks. It is also important to ensure that all connections remain tight and secure. Common issues that may arise include air leaks or reduced air flow, which can often be addressed by tightening connections or replacing worn components. Regular maintenance helps to ensure the longevity and performance of the connector 3.

Safety Considerations

When working with the Air Crossover Connector, it is important to observe several safety guidelines. This includes ensuring that the air system is depressurized before beginning any work to prevent injury from escaping air. Additionally, proper handling and inspection procedures should be followed to identify any potential issues before they lead to system failures. Understanding the potential hazards associated with high-pressure air systems is crucial for safe operation and maintenance 2.

Cummins Overview

Cummins is a renowned manufacturer in the automotive and heavy-duty truck industry, known for its commitment to quality and innovation. With a rich history of producing reliable and high-performance components, Cummins has established a strong reputation for excellence. Their products are designed with a focus on durability, efficiency, and compatibility, ensuring that they meet the demanding requirements of heavy-duty applications 3.

Cummins Air Crossover Connector 4967153 Compatibility

The Cummins Air Crossover Connector, part number 4967153, is a critical component in the air management system of several Cummins engine models. This part is designed to facilitate the efficient transfer of air between different sections of the engine, ensuring optimal performance and reliability.

QSK60 Engine

In the QSK60 engine, the Air Crossover Connector 4967153 plays a pivotal role in maintaining the balance of air pressure across the engine’s intake manifold. This engine, known for its robust design and high power output, benefits from the precise air management provided by this connector. It ensures that the air flow is evenly distributed, which is crucial for maintaining the engine’s efficiency and longevity 3.

CM850 and MCRS Engines

The CM850 and MCRS engines also utilize the Air Crossover Connector 4967153 to manage air flow effectively. These engines, often found in heavy-duty applications, require a reliable air management system to handle the high demands placed on them. The connector’s design ensures that the air flow is optimized, which helps in reducing the risk of engine overheating and improves overall performance 3.

By integrating the Air Crossover Connector 4967153 into these engines, Cummins ensures that the air management system operates smoothly, contributing to the engine’s reliability and efficiency. This part is a testament to Cummins’ commitment to providing high-quality components that enhance the performance of their engines 3.

Role of Part 4967153 Air Crossover Connector in Engine Systems

The 4967153 Air Crossover Connector is an essential component in the integration of various engine systems, ensuring seamless operation and communication between different parts.

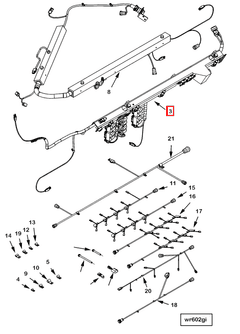

Integration with Harness

The Air Crossover Connector interfaces directly with the engine harness, facilitating the transfer of air flow data and control signals. This connection allows for precise monitoring and adjustment of air intake, which is vital for maintaining optimal engine performance. The harness, in turn, distributes these signals to other components, ensuring that the engine operates efficiently under varying conditions 4.

Interaction with Electronic Control Module (ECM) Wiring

The connector also plays a significant role in the ECM wiring system. By providing a stable and reliable connection point, it enables the ECM to receive accurate air flow readings. This data is critical for the ECM to make real-time adjustments to fuel injection and ignition timing, thereby enhancing overall engine efficiency and reducing emissions. The ECM wiring relies on the Air Crossover Connector to ensure that all air-related data is transmitted without interruption, allowing for consistent engine performance 4.

Conclusion

The Air Crossover Connector, part number 4967153, is a vital component in the air management systems of heavy-duty trucks and Cummins engines. Its role in ensuring efficient air distribution, integration with engine systems, and contribution to overall engine performance underscores its importance. Proper installation, maintenance, and understanding of safety considerations are essential for maximizing the benefits of this Cummins part.

-

David C Barton and John D Fieldhouse, Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body, Elsevier, 2009.

↩ -

Rudolf Limpert, Brake Design and Safety, Third Edition, SAE International, 2011.

↩ ↩ -

Haoran Hu, Rudy Smaling, Simon Baseley, Heavy-Duty Wheeled Vehicles, SAE International, 2014.

↩ ↩ ↩ ↩ ↩ ↩ -

Jon M. Quigley, SAE International’s Dictionary of Testing, Verification and Validation, SAE International, 2023.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.