This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

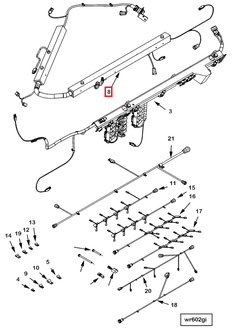

The 4967155 Electronic Control Module Wiring Harness is a component designed by Cummins to facilitate the operation of heavy-duty trucks. This wiring harness is integral to the truck’s electrical system, ensuring seamless communication between the Electronic Control Module (ECM) and various sensors and actuators. Cummins, a well-established manufacturer in the automotive industry, is known for its commitment to quality and innovation in producing reliable automotive components 1.

Basic Concepts of Electronic Control Module Wiring Harness

An Electronic Control Module Wiring Harness is a network of wires and connectors that link the ECM to different sensors and actuators within the truck. This harness plays a role in transmitting signals and power between the ECM and other electronic components, enabling the ECM to monitor and control various functions of the truck. The components of the wiring harness include wires, connectors, and protective coverings, all designed to withstand the demanding conditions of heavy-duty truck operations 2.

Purpose of the 4967155 Electronic Control Module Wiring Harness

The 4967155 Wiring Harness is specifically designed to enhance the operation of heavy-duty trucks by providing a reliable connection between the ECM and the truck’s electronic components. It facilitates the transmission of data and power, allowing the ECM to effectively manage engine performance, fuel efficiency, and emissions. This wiring harness ensures that the ECM receives accurate information from sensors and can send appropriate signals to actuators, contributing to the overall functionality and efficiency of the truck 3.

Key Features

The 4967155 Wiring Harness is characterized by several key features that enhance its performance and durability. Its design incorporates high-quality materials that are resistant to wear, corrosion, and environmental factors. The harness is engineered to fit precisely within the truck’s electrical system, ensuring secure and efficient connections. Additionally, it includes protective coverings to shield the wires from physical damage and harsh conditions, contributing to its longevity and reliability 4.

Benefits

The 4967155 Wiring Harness offers several benefits that contribute to the efficiency and safety of heavy-duty trucks. Improved reliability is one of the primary advantages, as the harness ensures consistent and accurate communication between the ECM and other components. Enhanced performance is another benefit, as the harness supports optimal engine operation and fuel efficiency. Furthermore, the design of the harness simplifies maintenance, allowing for easier access to connections and reducing the likelihood of issues arising from poor fitment or connection 5.

Installation and Integration

When installing the 4967155 Wiring Harness, it is important to follow guidelines to ensure proper fitment and connection within the truck’s electrical system. Careful attention should be paid to the routing of the wires to avoid interference with other components and to protect them from physical damage. Secure connections are vital to maintain the integrity of the electrical system, and any modifications should be made with consideration for the harness’s design and the truck’s specific requirements 6.

Troubleshooting and Maintenance

Common issues with the 4967155 Wiring Harness may include loose connections, damaged wires, or corrosion. Troubleshooting steps involve inspecting the harness for visible signs of damage, ensuring all connections are secure, and testing the electrical continuity of the wires. Regular maintenance, such as cleaning connections and checking for wear, can help prevent issues and ensure the longevity and optimal performance of the wiring harness 7.

Cummins: Manufacturer Overview

Cummins is a reputable manufacturer with a long history in the automotive industry. The company is known for its commitment to quality and innovation in producing automotive components. Cummins’ reputation is built on its dedication to developing reliable and efficient products that meet the demanding requirements of heavy-duty truck operations. The company’s focus on research and development ensures that its components, including the 4967155 Wiring Harness, are at the forefront of technological advancement in the industry 8.

Cummins Engine Compatibility with Electronic Control Module Wiring Harness (Part 4967155)

The Electronic Control Module (ECM) Wiring Harness, identified by part number 4967155, is a critical component in the electrical system of various Cummins engines. This wiring harness is designed to facilitate the connection between the ECM and other electronic control units, ensuring seamless communication and operation of the engine’s electronic systems.

QSK60 Engine

The QSK60 engine, known for its robust performance and reliability, integrates the ECM Wiring Harness to manage the complex electrical network that controls engine functions. This harness ensures that the ECM can effectively communicate with sensors and actuators, optimizing engine performance and efficiency.

CM850 Engine

In the CM850 engine, the ECM Wiring Harness is essential for maintaining the integrity of the engine’s electronic control systems. This harness is designed to withstand the demanding conditions of heavy-duty applications, providing a reliable connection that supports the engine’s operational needs.

MCRS Engine

The MCRS engine, which is part of the Cummins Marine product line, also utilizes the ECM Wiring Harness to manage its electronic systems. This harness is crucial for ensuring that the ECM can accurately control the engine’s performance, adapting to the unique demands of marine environments.

Grouping of Engines

The ECM Wiring Harness (4967155) is compatible with the QSK60, CM850, and MCRS engines, highlighting its versatility and importance across different engine types. This compatibility ensures that the harness can be used in various applications, from industrial and commercial to marine settings, providing a standardized solution for managing engine electronics.

Role of Part 4967155 Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module (ECM) Wiring Harness, identified by part number 4967155, serves as the vital link between the ECM and various engine components. This harness facilitates the transmission of electrical signals and power necessary for the ECM to monitor and control engine operations effectively.

Integration with Engine Components

-

Sensors: The harness connects a multitude of sensors, such as the Mass Air Flow (MAF) sensor, Oxygen (O2) sensors, and Manifold Absolute Pressure (MAP) sensor. These sensors provide real-time data to the ECM, allowing it to make precise adjustments to fuel injection, ignition timing, and other critical parameters.

-

Actuators: It interfaces with actuators including the fuel injectors, throttle body, and various solenoids. The ECM uses the harness to send commands to these components, ensuring that the engine operates within optimal performance and emission standards.

-

Ignition System: The harness is responsible for linking the ECM to the ignition coils and spark plugs. This connection enables the ECM to control the timing and duration of spark events, which is essential for efficient combustion.

-

Power Supply: It ensures a consistent power supply to the ECM from the battery and alternator, maintaining the ECM’s functionality even during varying electrical loads.

-

Communication Networks: In modern engine systems, the harness also connects the ECM to the vehicle’s Controller Area Network (CAN) bus. This allows the ECM to communicate with other control modules, such as the Transmission Control Module (TCM) and Anti-lock Braking System (ABS), enhancing overall vehicle performance and safety.

-

Grounding: Proper grounding is facilitated through the harness, which is essential for stable electrical performance and to prevent issues such as electrical noise and interference.

By effectively integrating these components, the ECM Wiring Harness ensures that the engine system operates smoothly, efficiently, and reliably.

Conclusion

The 4967155 Electronic Control Module Wiring Harness is a critical component in the operation of heavy-duty trucks, ensuring seamless communication between the ECM and various sensors and actuators. Its design, featuring high-quality materials and protective coverings, enhances its durability and reliability. The harness supports optimal engine performance, fuel efficiency, and emissions control, contributing to the overall functionality and safety of the truck. Proper installation, maintenance, and troubleshooting are essential to ensure the longevity and effectiveness of this Cummins part.

-

Dixon, John. Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning, 2010.

↩ -

ElGindy, Moustafa and ElSayegh, Zeinab. Road and Off-Road Vehicle Dynamics. Springer Nature, 2023.

↩ -

Harrison, Matthew. Controlling Noise and Vibration in Road Vehicles. SAE International, 2004.

↩ -

Halderman, James D. Automotive Principles: Diagnosis and Service. Prentice Hall, 2012.

↩ -

Cummins Inc. Owners Manual. Bulletin Number 5660043, 2023.

↩ -

Cummins Inc. Owners Manual. Bulletin Number 5660043, 2023.

↩ -

Cummins Inc. Owners Manual. Bulletin Number 5660043, 2023.

↩ -

Cummins Inc. Owners Manual. Bulletin Number 5660043, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.