This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

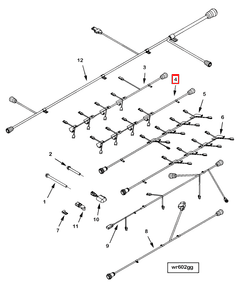

The 4967162 Electronic Control Module Wiring Harness is a vital component in the electrical system of commercial trucks. It facilitates communication between the electronic control module (ECM) and various sensors and actuators throughout the vehicle. This harness ensures that the ECM receives accurate data and can effectively control the truck’s systems, contributing to overall performance and efficiency.

Basic Concepts of Electronic Control Module Wiring Harness

An Electronic Control Module Wiring Harness is a network of wires and connectors that link the ECM to other electronic components within the truck. It consists of multiple wires, each serving a specific function, bundled together for protection and organization. The harness allows for the transmission of signals and power between the ECM and components such as sensors, actuators, and other control units. This system is integral to the truck’s electrical architecture, enabling precise control and monitoring of various functions 1.

Role of the 4967162 Electronic Control Module Wiring Harness in Truck Operation

The 4967162 Wiring Harness plays a significant role in the operation of a commercial truck by ensuring seamless communication between the ECM and other electronic components. It allows the ECM to receive data from sensors, which monitor parameters such as engine temperature, fuel levels, and emissions. Based on this data, the ECM can adjust engine performance, fuel injection timing, and other functions to optimize efficiency and compliance with emissions standards. Additionally, the harness enables the ECM to send commands to actuators, controlling functions like fuel injectors, turbochargers, and exhaust gas recirculation valves 2.

Key Features of the 4967162 Wiring Harness

The 4967162 Wiring Harness is designed with several key features that enhance its performance and durability. It is constructed using high-quality materials resistant to corrosion, abrasion, and extreme temperatures, ensuring longevity in harsh operating environments. The harness is meticulously engineered to meet stringent industry standards, providing reliable signal transmission and power distribution. Its design includes robust connectors and terminals that ensure secure and consistent connections, minimizing the risk of signal loss or electrical faults 3.

Benefits of Using the 4967162 Wiring Harness

Utilizing the 4967162 Wiring Harness offers several benefits. It contributes to improved reliability by ensuring consistent and accurate data transmission between the ECM and other components. This results in enhanced engine performance, fuel efficiency, and emissions control. The harness is also designed for ease of maintenance, with accessible connectors and terminals that simplify diagnostic and repair processes. Its durable construction reduces the likelihood of failures, leading to lower downtime and maintenance costs.

Installation Process

Installing the 4967162 Wiring Harness involves several steps to ensure proper integration into the truck’s electrical system. Begin by disconnecting the battery to prevent any electrical shorts. Identify the location where the harness will be installed, ensuring it is routed away from sharp edges and moving parts to avoid damage. Connect the harness to the ECM and other components using the provided connectors, ensuring all connections are secure and properly aligned. Finally, reattach the battery and perform a system check to verify that all connections are functioning correctly.

Troubleshooting Common Issues

Common issues with the 4967162 Wiring Harness may include loose connections, damaged wires, or faulty connectors. To troubleshoot these problems, begin by visually inspecting the harness for any signs of wear or damage. Check all connections to ensure they are secure and properly seated. Use a multimeter to test for continuity and identify any breaks in the wiring. If a fault is detected, repair or replace the affected section of the harness as necessary.

Maintenance Tips

To ensure the longevity and optimal performance of the 4967162 Wiring Harness, regular maintenance is recommended. Inspect the harness periodically for signs of wear, corrosion, or damage. Clean the connectors and terminals to remove any dirt or debris that may interfere with signal transmission. Ensure that the harness is properly routed and secured to prevent damage from vibrations or contact with other components. Following these maintenance practices will help maintain the integrity of the electrical system and ensure reliable operation.

About Cummins

Cummins is a renowned manufacturer in the commercial truck industry, known for its high-quality engines and components. With a rich history of innovation and excellence, Cummins has established a strong reputation for producing reliable and efficient products. The company offers a comprehensive range of solutions designed to meet the demanding requirements of commercial trucking, ensuring optimal performance and durability in various applications.

Understanding the Role of Part 4967162 Electronic Control Module Wiring Harness in Engine Systems

The part 4967162 Electronic Control Module (ECM) Wiring Harness is an integral component in modern engine systems, facilitating seamless communication and power distribution between the ECM and various engine components. This harness is meticulously designed to ensure reliable and efficient operation of the engine by connecting the ECM to sensors, actuators, and other control units.

Integration with Engine Components

-

Sensors: The ECM Wiring Harness connects various sensors such as the Mass Air Flow (MAF) sensor, Oxygen (O2) sensors, and Manifold Absolute Pressure (MAP) sensor to the ECM. These sensors provide real-time data on air intake, oxygen levels, and pressure within the intake manifold, allowing the ECM to make precise adjustments to fuel delivery and ignition timing.

-

Actuators: This harness also links the ECM to actuators including the fuel injectors, throttle body, and variable valve timing (VVT) solenoids. By receiving signals from the ECM, these actuators adjust fuel injection rates, throttle position, and valve timing to optimize engine performance and efficiency.

-

Ignition System: The harness ensures a secure connection between the ECM and the ignition system components such as the ignition coils and spark plugs. This allows the ECM to control the timing and duration of spark events, crucial for combustion efficiency and overall engine performance.

-

Transmission Control Module (TCM): In vehicles with automatic transmissions, the ECM Wiring Harness interfaces with the TCM. This connection enables the ECM to communicate with the transmission, adjusting shift patterns based on driving conditions and engine load.

-

Emission Control Systems: The harness also plays a role in connecting the ECM to emission control components like the Exhaust Gas Recirculation (EGR) valve and the Evaporative Emission Control (EVAP) system. This ensures that the engine operates within environmental regulations by managing emissions effectively.

-

Battery and Alternator: Power distribution is another significant function of the ECM Wiring Harness. It connects the ECM to the vehicle’s battery and alternator, ensuring a stable power supply for the ECM and other electronic components.

Enhanced Engine Management

By providing a robust and reliable connection between the ECM and various engine components, the part 4967162 ECM Wiring Harness enhances the overall management of the engine. It allows for real-time monitoring and adjustment of engine parameters, leading to improved performance, fuel efficiency, and reduced emissions.

Conclusion

In summary, the ECM Wiring Harness is a foundational element in the intricate network of an engine system, ensuring that all components work in harmony under the supervision of the ECM.

-

Heavy Duty Truck Systems Fifth Edition, Sean Bennett, Ian Andrew Norman, Delmar Cengage Learning, 2011

↩ -

Automotive Transmissions Fundamentals Selection Design and Application, Harald Naunheimer, Bernd Bertsche, Joachim Ryborz, Wolfgang Novak, Springer Vieweg, 2011

↩ -

Bosch Automotive Handbook 9th Edition, Robert Bosch GmbH, Robert Bosch GmbH, 2014

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.