This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

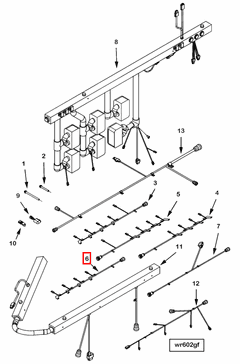

The Electronic Control Module (ECM) Wiring Harness, part number 4967168, manufactured by Cummins, is a critical component in the operation of heavy-duty trucks. This wiring harness is designed to facilitate communication between the ECM and various other systems within the truck, ensuring seamless data transmission and operation. Cummins, a well-established manufacturer in the automotive industry, produces this component with a focus on reliability and performance 1.

Basic Concepts

The ECM serves as the brain of the truck, managing and regulating various operations such as engine performance, fuel injection, and emissions control. The wiring harness connects the ECM to other critical components and sensors throughout the vehicle, ensuring the truck’s overall functionality and efficiency 2.

Purpose of the ECM Wiring Harness

The ECM Wiring Harness is integral to the operation of a truck. It enables the ECM to communicate with and control various systems, including the engine, transmission, and braking systems. This communication is vital for the coordinated operation of these systems, ensuring optimal performance and efficiency. The harness also plays a role in data collection and diagnostics, allowing for more effective maintenance and troubleshooting 3.

Key Features

The ECM Wiring Harness is characterized by its robust design and high-quality materials. It is engineered to withstand the harsh conditions often encountered in heavy-duty truck operations. The harness features durable connectors and insulated wires, which enhance its performance and longevity. Additionally, its design allows for easy integration with the truck’s existing systems, facilitating a smooth installation process 4.

Benefits

Utilizing the ECM Wiring Harness offers several advantages. It contributes to improved reliability and performance of the truck’s systems by ensuring stable and efficient communication between the ECM and other components. The harness also simplifies diagnostics, as it allows for easier access to data and signals. This can lead to more efficient maintenance and quicker identification of issues 5.

Installation and Integration

Proper installation and integration of the ECM Wiring Harness are crucial for its effective operation. It is important to follow the manufacturer’s recommendations during the installation process to ensure compatibility and optimal performance. Careful attention to detail during installation can prevent potential issues and ensure the harness functions as intended within the truck’s system 6.

Troubleshooting and Maintenance

Common issues with the ECM Wiring Harness may include connector corrosion, wire damage, or signal interference. Regular inspection and maintenance can help identify and address these issues promptly. Cleaning connectors, checking for wire damage, and ensuring proper shielding can contribute to the longevity and optimal performance of the harness 7.

Safety Considerations

When working with the ECM Wiring Harness, it is important to adhere to safety protocols and guidelines. This includes ensuring the truck’s power is off during installation or maintenance to prevent electrical shocks. Additionally, using the appropriate tools and following safety standards can help protect both the technician and the equipment 8.

Cummins Overview

Cummins is a renowned name in the automotive industry, particularly known for its heavy-duty truck components. With a rich history of innovation and quality, Cummins has established a strong reputation for producing reliable and high-performance parts. Their commitment to excellence is evident in the design and manufacturing of components like the ECM Wiring Harness 9.

Conclusion

The ECM Wiring Harness part 4967168 by Cummins is a sophisticated component that plays a significant role in the operation of heavy-duty trucks. Its design, features, and benefits contribute to the overall efficiency and reliability of the vehicle. Proper installation, maintenance, and adherence to safety considerations are key to ensuring its optimal performance.

-

Stone, R. (2012). Introduction to Internal Combustion Engines, Fourth Edition. Macmillan.

↩ -

Mom, G. (2023). The Evolution of Automotive Engineering: A Handbook. SAE International.

↩ -

Hilgers, M. (2023). Electrical Systems and Mechatronics, Second Edition. Springer Vieweg.

↩ -

Limpert, R. (2011). Brake Design and Safety, Third Edition. SAE International.

↩ -

Stone, R. (2012). Introduction to Internal Combustion Engines, Fourth Edition. Macmillan.

↩ -

Mom, G. (2023). The Evolution of Automotive Engineering: A Handbook. SAE International.

↩ -

Hilgers, M. (2023). Electrical Systems and Mechatronics, Second Edition. Springer Vieweg.

↩ -

Limpert, R. (2011). Brake Design and Safety, Third Edition. SAE International.

↩ -

Mom, G. (2023). The Evolution of Automotive Engineering: A Handbook. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.