This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

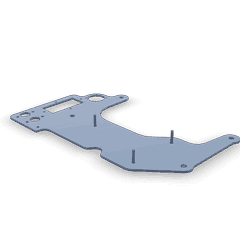

The Electronic Control Module Bracket, identified by part number 4996704, is a component manufactured by Cummins, a well-established name in the commercial truck industry. This Cummins part plays a significant role in the operational framework of trucks, providing a secure mounting solution for the Electronic Control Module (ECM). Its design and functionality are integral to the efficient and reliable operation of truck systems.

Function and Role

The Electronic Control Module Bracket serves as a foundational component in the truck’s electronic system. It securely holds the ECM in place, ensuring that the module remains stable and protected during operation. The bracket facilitates the connection between the ECM and various truck systems, including the wiring harnesses and other electronic components. This interaction is vital for the seamless transmission of data and signals that govern the truck’s performance and operational parameters 1.

Key Features

The 4996704 is characterized by several key features that enhance its performance and durability. Constructed from high-strength materials, it offers robust protection for the ECM. Its design incorporates precise mounting points and secure attachment mechanisms, ensuring a stable and vibration-resistant installation. Additionally, the bracket is engineered to withstand the harsh environmental conditions typically encountered in truck operations, contributing to its longevity and reliability 2.

Benefits

The installation of the Electronic Control Module Bracket provides several benefits. It offers enhanced protection for the ECM, safeguarding it against physical damage and environmental factors. The bracket also contributes to the overall stability of the ECM, ensuring consistent and reliable performance. Furthermore, by securing the ECM in place, the bracket plays a role in maintaining the integrity of the truck’s electronic systems, thereby contributing to the vehicle’s reliability and performance 3.

Installation Process

Installing the Electronic Control Module Bracket requires careful attention to detail to ensure proper setup. The process involves securing the bracket to the designated mounting points within the truck’s chassis, followed by the attachment of the ECM to the bracket. It is important to follow the manufacturer’s guidelines for torque specifications and attachment methods to ensure a secure and stable installation. Additionally, verifying the alignment and connectivity of the ECM with the truck’s wiring harnesses is crucial for optimal operation 4.

Maintenance and Troubleshooting

Regular maintenance of the Electronic Control Module Bracket is important to ensure its continued performance and durability. This includes inspecting the bracket for signs of wear or damage, ensuring that all attachment points remain secure, and verifying the integrity of the ECM’s connection to the bracket and wiring harnesses. Common issues may include loose connections or bracket misalignment, which can be addressed through re-tightening or re-alignment as necessary. Regular checks and maintenance can help prevent more significant problems down the line.

Integration With Truck Systems

The Electronic Control Module Bracket integrates seamlessly with various truck systems, playing a key role in the operation of the ECM and the overall electronic framework of the vehicle. It ensures a stable and secure platform for the ECM, facilitating its interaction with wiring harnesses and other electronic components. This integration is important for the accurate and reliable transmission of data and signals that govern the truck’s performance, fuel efficiency, and operational parameters.

Safety Considerations

When handling and installing the Electronic Control Module Bracket, it is important to observe safety protocols to prevent accidents and ensure safe operation. This includes wearing appropriate personal protective equipment, ensuring the truck is securely parked and the engine is off during installation, and following all manufacturer guidelines for torque specifications and attachment methods. Additionally, being aware of the bracket’s location within the truck’s chassis and its interaction with other components can help prevent accidental damage during installation or maintenance procedures.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s commitment to excellence is reflected in its product range, which includes components like the 4996704 Electronic Control Module Bracket, designed to meet the demanding requirements of truck operations.

Conclusion

The 4996704 Electronic Control Module Bracket is a critical component in the efficient and reliable operation of truck systems. Its robust design, integration with truck systems, and the benefits it offers in terms of protection and stability make it an indispensable part of modern truck technology. Regular maintenance and adherence to safety protocols during installation are essential to ensure its optimal performance and longevity.

-

Hilgers, Michael. Transmissions and Drivetrain Design. Springer Vieweg, 2022.

↩ -

Lakshminarayanan, P. A., and Nayak, Nagaraj S. Critical Component Wear in Heavy Duty Engines. John Wiley & Sons, 2011.

↩ -

Bonnick, Allan, and Newbold, Derek. A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd, 2011.

↩ -

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.