This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The 4998576 Electronic Control Module Wiring Loom, manufactured by Cummins, is a vital component in the operation of commercial trucks. Cummins, a well-established name in the commercial truck industry, produces this wiring loom to ensure efficient and reliable communication between the truck’s electronic control module (ECM) and various engine components. This part is integral to the truck’s electronic systems, facilitating optimal engine performance and overall vehicle operation.

Basic Concepts

Electronic Control Module Wiring Looms are designed to manage the electrical connections within a vehicle’s electronics and engine management systems. These looms consist of a network of wires and connectors that link the ECM to sensors, actuators, and other critical components. By providing a structured pathway for electrical signals, the wiring loom ensures that data is accurately transmitted, allowing the ECM to monitor and control engine functions effectively 1.

Function and Operation

The 4998576 Electronic Control Module Wiring Loom operates as the backbone of the truck’s electrical system. It connects the ECM to various engine components, enabling the ECM to receive data from sensors and send commands to actuators. This continuous flow of information allows the ECM to make real-time adjustments to engine parameters, ensuring smooth operation and optimal performance. The wiring loom is designed to withstand the harsh conditions of commercial truck environments, providing durable and reliable connections 2.

Purpose

The primary role of the 4998576 Electronic Control Module Wiring Loom is to facilitate communication between the ECM and the truck’s engine components. This communication is crucial for maintaining engine performance, enhancing fuel efficiency, and controlling emissions. By ensuring that the ECM receives accurate data and can issue precise commands, the wiring loom contributes to the overall efficiency and reliability of the truck 3.

Key Features

The 4998576 Electronic Control Module Wiring Loom is characterized by several notable features. It is constructed using high-quality materials that offer durability and resistance to environmental factors. The wiring configuration is designed to minimize interference and ensure reliable signal transmission. Additionally, the loom is engineered for seamless integration with Cummins engines and other systems, ensuring compatibility and ease of installation.

Benefits

The 4998576 Electronic Control Module Wiring Loom offers several advantages. Its robust construction and high-quality materials contribute to improved reliability and longevity. The efficient wiring configuration enhances the performance of the truck’s electronic systems, leading to better engine management. Furthermore, the streamlined design simplifies maintenance procedures, reducing downtime and repair costs.

Installation

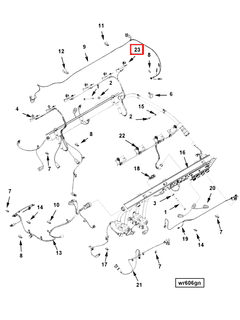

Proper installation of the 4998576 Electronic Control Module Wiring Loom is crucial for ensuring its effective operation. Recommended procedures include careful routing of the wires to avoid damage and secure fastening of all connections. It is important to follow the manufacturer’s guidelines to prevent potential issues such as short circuits or signal interference. Attention to detail during installation will ensure the wiring loom functions as intended.

Troubleshooting

Common issues with the 4998576 Electronic Control Module Wiring Loom may include loose connections, damaged wires, or interference from other electrical components. Troubleshooting steps involve inspecting all connections for security, checking wires for signs of wear or damage, and ensuring that the loom is properly routed away from potential sources of interference. Diagnosing and resolving these issues promptly will help maintain the efficiency of the truck’s electronic systems.

Maintenance

Regular maintenance of the 4998576 Electronic Control Module Wiring Loom is important for ensuring its continued reliable operation. Recommended practices include periodic inspection of all connections and wires for signs of wear or damage. Cleaning the loom to remove dirt and debris will help prevent corrosion and ensure optimal signal transmission. Replacement guidelines should be followed if any components show signs of significant wear or failure.

Cummins Overview

Cummins is a renowned manufacturer in the commercial truck industry, known for its high-quality engines and components. With a rich history of innovation and excellence, Cummins offers a wide range of products designed to enhance the performance and reliability of commercial vehicles. The company’s reputation for producing durable and efficient components makes it a trusted choice for fleet operators and maintenance professionals.

Electronic Control Module Wiring Loom for Cummins Engines

The Electronic Control Module (ECM) Wiring Loom, part number 4998576, is a critical component in the electrical system of certain Cummins engines. This wiring loom is designed to facilitate the connection between the ECM and various sensors, actuators, and other electronic components within the engine system.

For the QSK50 engines, specifically the CM2150 K107 and CM2150 MCRS variants, the ECM Wiring Loom ensures that the ECM can effectively communicate with the engine’s sensors and control units. This is essential for maintaining optimal engine performance, as the ECM relies on real-time data from these components to adjust engine parameters dynamically.

In these engines, the ECM Wiring Loom is meticulously engineered to withstand the harsh conditions typically found in industrial and heavy-duty applications. It is constructed with high-quality materials that provide durability and resistance to environmental factors such as heat, vibration, and moisture. This ensures a reliable and long-lasting connection, reducing the likelihood of electrical faults and enhancing the overall reliability of the engine.

The ECM Wiring Loom is a standardized component across the specified QSK50 engine models, allowing for ease of maintenance and repair. Technicians can quickly identify and replace the wiring loom if necessary, minimizing downtime and ensuring that the engine can return to operation swiftly.

By integrating seamlessly with the ECM and other electronic components, the ECM Wiring Loom plays a pivotal role in the efficient and reliable operation of the QSK50 CM2150 K107 and CM2150 MCRS engines.

Role of Part 4998576 Electronic Control Module Wiring Loom in Engine Systems

The part 4998576 Electronic Control Module (ECM) Wiring Loom is an integral component in the orchestration of various engine systems. It serves as the vital conduit that facilitates communication and power distribution between the ECM and other engine components.

Integration with the Harness

The ECM Wiring Loom interfaces seamlessly with the main engine harness. This connection ensures that signals and power are efficiently transmitted to and from the ECM. The loom’s design allows it to adapt to the complex routing requirements within the engine bay, maintaining signal integrity and reducing the risk of electrical interference.

Communication with the Electronic Control Module

The ECM relies on the wiring loom to receive inputs from sensors such as the Mass Air Flow (MAF) sensor, Manifold Absolute Pressure (MAP) sensor, and various temperature sensors. These inputs are essential for the ECM to make real-time adjustments to fuel delivery, ignition timing, and other critical parameters.

Power Distribution

In addition to signal transmission, the ECM Wiring Loom is responsible for distributing power to actuators such as the fuel injectors, ignition coils, and various solenoids. This ensures that the ECM can effectively control these components to optimize engine performance and efficiency.

Diagnostic Capabilities

The wiring loom also plays a role in diagnostic capabilities. It provides pathways for the ECM to communicate with onboard diagnostic (OBD) systems, allowing for the retrieval of fault codes and real-time data monitoring. This facilitates easier troubleshooting and maintenance.

Enhanced Reliability

By centralizing the wiring connections through the ECM Wiring Loom, the engine system benefits from enhanced reliability. The loom is designed to withstand the harsh environment of the engine bay, including exposure to heat, vibration, and moisture. This durability ensures consistent performance over the lifespan of the engine.

Conclusion

In summary, the 4998576 ECM Wiring Loom is a foundational element that enables the ECM to effectively manage and control various engine systems, ensuring optimal performance and reliability. Its robust construction, efficient design, and seamless integration with Cummins engines make it a critical component in the operation of commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.