This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

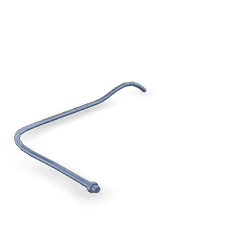

The Electronic Control Module Wiring Harness (Part #4998658) by Cummins is a specialized component designed for use in commercial trucks. This wiring harness serves as a link in the truck’s electrical system, facilitating communication between the Electronic Control Module (ECM) and various electronic components throughout the vehicle. Its role is significant in ensuring the efficient and reliable operation of the truck’s electronic systems.

Basic Concepts

Electronic Control Module Wiring Harnesses are integral to the electrical systems of modern trucks. They function by providing a structured pathway for electrical signals and power to travel between the ECM and other electronic components. This includes sensors, actuators, and other control units that are essential for the operation of the truck. The wiring harness is designed to manage these connections efficiently, ensuring that data and power are transmitted accurately and reliably 1.

Purpose and Functionality

The Electronic Control Module Wiring Harness plays a role in the operation of a truck by enabling the ECM to communicate with and control various electronic systems. This includes engine management, transmission control, and other functions. The harness is responsible for carrying signals and power to and from the ECM, allowing it to monitor and adjust the truck’s performance in real-time. This interaction is vital for the truck’s overall operation, contributing to its efficiency, reliability, and safety.

Key Features

The Cummins Electronic Control Module Wiring Harness is characterized by its robust design and high-quality materials. It is engineered to withstand the harsh conditions often encountered in commercial trucking, including exposure to extreme temperatures, vibrations, and moisture. The harness is constructed using durable materials that ensure longevity and reliability. Additionally, it features a streamlined design that simplifies installation and integration into the truck’s electrical system.

Benefits

Utilizing the Cummins Electronic Control Module Wiring Harness offers several advantages. It provides improved reliability and efficiency in the truck’s electronic systems, contributing to overall performance. The harness is designed for ease of installation, reducing downtime and simplifying maintenance procedures. Its compatibility with a wide range of truck models and ECMs makes it a versatile solution for fleet operators.

Installation and Integration

Proper installation and integration of the Electronic Control Module Wiring Harness are important for ensuring its effectiveness. It is important to follow manufacturer guidelines to ensure compatibility with the specific truck model and ECM. Careful attention to detail during installation will help prevent issues such as poor connections or damage to the harness, ensuring optimal performance and longevity.

Troubleshooting and Maintenance

Regular maintenance and prompt troubleshooting are key to ensuring the Electronic Control Module Wiring Harness operates efficiently. Common issues may include loose connections, damaged wires, or corrosion. Regular inspections and cleaning can help prevent these problems. In the event of a malfunction, systematic troubleshooting procedures should be followed to identify and resolve the issue.

Safety Considerations

When working with the Electronic Control Module Wiring Harness, it is important to adhere to safety guidelines. This includes proper handling, installation, and maintenance procedures to prevent accidents. Ensuring that the harness is correctly installed and maintained will help prevent electrical issues that could pose a risk to the operator or the vehicle.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the automotive industry, Cummins is committed to innovation and quality in manufacturing automotive components. Their products are known for their reliability, efficiency, and durability, making them a preferred choice for commercial truck operators 2.

Role of Part 4998658 Electronic Control Module Wiring Harness in Engine Systems

The 4998658 Electronic Control Module (ECM) Wiring Harness is an integral component in the orchestration of various engine systems, ensuring seamless communication and operation between the ECM and other vital engine components.

Integration with Sensors

The ECM Wiring Harness facilitates the connection between the ECM and an array of sensors distributed throughout the engine system. These sensors, such as the Oxygen (O2) Sensor, Mass Air Flow (MAF) Sensor, and Manifold Absolute Pressure (MAP) Sensor, relay real-time data to the ECM. This data encompasses air-fuel ratio, air flow rate, and manifold pressure, respectively. The harness ensures that the ECM receives accurate and timely information, enabling it to make precise adjustments to fuel injection, ignition timing, and other parameters for optimal engine performance.

Oxygen Sensor Communication

A significant aspect of the ECM Wiring Harness’s role is its interaction with the Oxygen Sensor. The harness provides the necessary electrical connections for the O2 Sensor to transmit data regarding the oxygen content in the exhaust gases back to the ECM. This information is pivotal for the ECM to determine the air-fuel mixture’s richness or leanness. Based on this data, the ECM can adjust the fuel injector’s operation to maintain an ideal air-fuel ratio, which is essential for efficient combustion, reduced emissions, and improved fuel economy.

Overall Engine System Coordination

Beyond sensor integration, the ECM Wiring Harness plays a part in coordinating the operation of other engine components, such as the fuel injectors, ignition coils, and various actuators. It serves as the nervous system of the engine, transmitting commands from the ECM to these components and feedback from them to the ECM. This bidirectional communication is essential for the dynamic adjustment of engine parameters in response to driving conditions, load demands, and other variables.

Conclusion

In summary, the 4998658 ECM Wiring Harness is a fundamental component in the engine’s electronic control system, facilitating the intricate dance of data exchange and command execution that underpins modern engine management. Its role in connecting the ECM with sensors and other engine components ensures that the engine operates efficiently, reliably, and in compliance with emissions standards.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.