This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

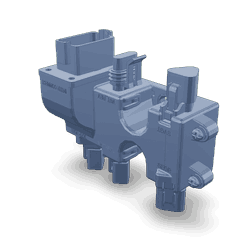

The Cummins 5257767 Electrical Connector is a specialized component designed for use in commercial truck operations. This connector plays a role in ensuring the reliable operation of the truck’s electrical system by facilitating secure and efficient electrical connections, which are vital for the performance and safety of the vehicle 1.

Basic Concepts of Electrical Connectors

Electrical connectors are devices used to join electrical circuits together, allowing the transfer of electrical power and signals between different components. They function by providing a secure and reliable connection that can be easily disconnected when necessary. In vehicle electrical systems, connectors are important for linking various electrical components, such as sensors, lights, and control units, ensuring that the system operates smoothly and efficiently 2.

Purpose of the 5257767 Electrical Connector

The Cummins 5257767 Electrical Connector is specifically designed to play a role in the electrical system of a truck. It ensures that electrical connections are maintained securely, which is important for the consistent operation of the vehicle’s electrical components. This connector is used in various applications within the truck, contributing to the overall functionality and reliability of the electrical system 3.

Key Features

The Cummins 5257767 Electrical Connector is characterized by several key features that enhance its performance. Its design incorporates high-quality materials that provide durability and resistance to environmental factors. The connector is engineered to offer a secure fit, minimizing the risk of disconnection or poor contact. Additionally, it features unique characteristics such as corrosion resistance and robust construction, which are particularly beneficial in the demanding conditions of commercial truck operations.

Benefits

The Cummins 5257767 Electrical Connector offers several benefits that contribute to its effectiveness in heavy-duty applications. It provides improved electrical conductivity, ensuring that signals and power are transmitted efficiently. The connector’s durability and reliability are enhanced by its robust construction and resistance to wear and environmental factors. These qualities make it a valuable component for maintaining the performance and safety of commercial trucks.

Installation and Usage

Proper installation of the Cummins 5257767 Electrical Connector is important to ensure its effective operation. Guidelines provided by Cummins should be followed to achieve a secure and reliable connection. This includes ensuring that the connector is correctly aligned and firmly seated in its housing. Regular checks and maintenance can help prevent issues and ensure the connector continues to perform optimally.

Troubleshooting and Maintenance

Common issues with the Cummins 5257767 Electrical Connector may include poor connections or signs of wear. Troubleshooting these issues involves checking the connector for signs of damage, ensuring it is securely fitted, and cleaning any corrosion that may have formed. Regular maintenance, such as inspecting the connector for wear and ensuring it remains free of debris, can help extend its lifespan and maintain its performance.

Safety Considerations

When working with the Cummins 5257767 Electrical Connector, it is important to observe safety precautions. This includes ensuring that the vehicle’s electrical system is de-energized before beginning any work to prevent the risk of electrical shock. Additionally, using the appropriate tools and following manufacturer guidelines can help ensure a safe and effective installation or repair process.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history of innovation and commitment to quality, Cummins plays a significant role in the commercial truck industry. The company’s products, including the Cummins 5257767 Electrical Connector, are designed to meet the rigorous demands of heavy-duty applications, ensuring reliability and performance in various operating conditions.

Cummins Engine Electrical Connector Part 5257767

The Cummins Electrical Connector part number 5257767 is designed to integrate seamlessly with a range of Cummins engines, ensuring reliable electrical connections and optimal performance. This part is specifically engineered to fit the following Cummins engines:

- QSB6.7 CM2250

- QSC9 CM2250/QSL9 CM2250

These engines are known for their robust design and efficiency, often utilized in a variety of applications from industrial machinery to agricultural equipment. The Electrical Connector part 5257767 is crucial for maintaining the integrity of the electrical system in these engines, facilitating the transfer of power and signals between various components.

For the QSB6.7 CM2250, the connector ensures that all electrical pathways are secure, reducing the risk of intermittent connections that could lead to performance issues or failures. Similarly, for the QSC9 CM2250/QSL9 CM2250 engines, the part plays a vital role in maintaining consistent electrical communication, which is essential for the engines’ complex control systems.

By using the Cummins Electrical Connector part 5257767, users can expect enhanced reliability and longevity of their engine’s electrical systems, minimizing downtime and maintenance costs.

Role of Electrical Connector 5257767 in Engine Systems

In modern engine systems, the Electrical Connector 5257767 serves as a vital link facilitating seamless communication and power distribution between various components. Specifically, it plays a significant role in the Air Intake Connection and the Electronic Control Module (ECM) Wiring Harness.

Air Intake Connection

The Air Intake Connection is responsible for regulating the airflow into the engine. The Electrical Connector 5257767 ensures that the sensors and actuators within this system receive the necessary electrical signals to function correctly. This includes providing power to the Mass Air Flow (MAF) sensor, which measures the amount of air entering the engine, and to the throttle position sensor, which monitors the position of the throttle plate. Accurate data from these sensors allows the ECM to make precise adjustments to fuel delivery and ignition timing, optimizing engine performance and efficiency.

Electronic Control Module (ECM) Wiring Harness

The ECM Wiring Harness is the central nervous system of the engine, connecting the ECM to various sensors, actuators, and other control units throughout the engine system. Electrical Connector 5257767 is integral to this harness, ensuring reliable and consistent electrical connections. It transmits data from the ECM to components such as fuel injectors, ignition coils, and various solenoids, allowing the ECM to execute its control strategies effectively. Additionally, it receives feedback from these components, enabling the ECM to make real-time adjustments to maintain optimal engine operation.

By maintaining secure and efficient electrical connections, Electrical Connector 5257767 contributes to the overall reliability and performance of the engine system. Its role in both the Air Intake Connection and the ECM Wiring Harness underscores its importance in ensuring that all engine components work harmoniously together.

Conclusion

The Cummins 5257767 Electrical Connector is a critical component in the electrical systems of commercial trucks and Cummins engines. Its design and features ensure reliable and efficient electrical connections, contributing to the overall performance and safety of the vehicle. Proper installation, maintenance, and adherence to safety guidelines are essential to maximize the benefits of this connector.

-

Hilgers, Michael. Transmissions and Drivetrain Design. Springer Vieweg, 2022.

↩ -

Miedema, S. A., and Z. Lu. The Dynamic Behavior of a Diesel Engine. Published by Drir S. A. Miedema, 2010.

↩ -

Reif, Konrad, ed. Brakes Brake Control and Driver Assistance Systems Function Regulation and Components. Springer, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.