This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

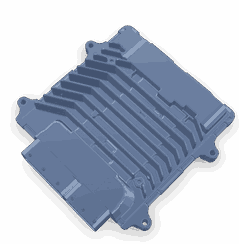

The Cummins 5258888 Electronic Control Module (ECM) is a sophisticated component designed to enhance the operation of commercial trucks. It serves as the central processing unit for the engine’s electronic systems, ensuring optimal performance and efficiency. The significance of the ECM lies in its ability to manage complex engine functions, thereby contributing to the overall reliability and effectiveness of truck operations 1.

Basic Concepts of Electronic Control Modules

An Electronic Control Module (ECM) is a computer that controls various functions within a vehicle’s engine system. It processes data from numerous sensors and adjusts engine parameters in real-time to ensure efficient operation. In heavy-duty trucks, ECMs play a vital role by integrating with other systems to manage fuel injection, emissions, and engine timing. This integration allows for precise control over engine performance and compliance with environmental regulations 2.

Purpose and Functionality

The Cummins 5258888 ECM is specifically designed to manage and regulate various engine functions and systems within commercial trucks. It oversees critical operations such as fuel delivery, ignition timing, and emissions control. By continuously monitoring sensor data and making necessary adjustments, the ECM ensures that the engine operates within optimal parameters, enhancing both performance and reliability 3.

Key Features

The Cummins 5258888 ECM boasts several primary features that set it apart. Its design incorporates advanced technology to provide robust performance under demanding conditions. The build quality ensures durability and longevity, while its technological advancements allow for precise control over engine functions. Additionally, the ECM is compatible with a range of truck models and engine types, making it a versatile component in the commercial trucking industry.

Benefits of Using Cummins 5258888 ECM

Utilizing the Cummins 5258888 ECM offers several advantages. It contributes to improved engine performance by optimizing fuel delivery and ignition timing. This results in enhanced fuel efficiency, reducing operational costs. Moreover, the ECM’s reliable operation minimizes downtime, leading to increased productivity. These benefits collectively impact overall truck operation and maintenance, providing a more efficient and cost-effective solution for fleet managers.

Installation and Integration

Proper installation and integration of the Cummins 5258888 ECM are crucial for seamless functionality. The process involves several steps, including preparing the truck’s electrical system, connecting the ECM to the appropriate sensors and actuators, and configuring the module to match the specific engine and truck model. Careful attention to these steps ensures that the ECM operates effectively within the truck’s system.

Troubleshooting and Maintenance

To maintain the Cummins 5258888 ECM’s performance, regular troubleshooting and maintenance are necessary. Common issues may include sensor malfunctions or software glitches. Best practices for troubleshooting involve using diagnostic tools to identify problems and following manufacturer guidelines for repairs. Maintenance tips include keeping the ECM clean and dry, regularly updating its software, and performing routine checks to ensure all connections are secure.

Diagnostic Capabilities

The Cummins 5258888 ECM is equipped with diagnostic features that aid in identifying and resolving engine-related issues. These capabilities allow technicians to monitor engine performance in real-time, diagnose problems quickly, and make necessary adjustments. The diagnostic information provided by the ECM is invaluable for maintaining engine health and ensuring compliance with emissions standards.

Impact on Driver Experience

The Cummins 5258888 ECM influences the driving experience by enhancing engine responsiveness and ease of operation. Drivers benefit from smoother acceleration, better fuel economy, and reduced emissions. The ECM’s precise control over engine functions also contributes to overall comfort by maintaining consistent performance, even under varying load conditions.

Environmental and Efficiency Considerations

The Cummins 5258888 ECM plays a role in reducing emissions and enhancing fuel efficiency. By optimizing engine operations, it helps trucks meet stringent environmental regulations and standards. This not only contributes to a cleaner environment but also reduces the carbon footprint of commercial trucking operations. The ECM’s efficient management of engine functions ensures that trucks operate within the bounds of environmental compliance while maximizing fuel economy.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the automotive industry, known for its commitment to innovation and quality. Founded in 1919, Cummins has a long history of producing reliable engine components. The company’s dedication to advancing technology and maintaining high manufacturing standards has established it as a trusted name in the commercial trucking sector. Cummins continues to lead the way in developing cutting-edge solutions that enhance engine performance and efficiency.

Compatibility of Cummins Part 5258888 with Various Engines

The Cummins part 5258888, an Electronic Control Module (ECM), is designed to integrate seamlessly with a range of engine models. This ECM is engineered to ensure optimal performance and reliability across different engine configurations.

ISF2.8 CM2220 F129

The ECM part 5258888 is compatible with the ISF2.8 CM2220 F129 engine. This integration ensures that the ECM can effectively manage the engine’s operations, providing precise control over fuel injection, ignition timing, and other critical functions.

ISF3.8 CM2220 AN and ISF3.8 CM2220 F103

Both the ISF3.8 CM2220 AN and ISF3.8 CM2220 F103 engines are designed to work with the Cummins part 5258888 ECM. This compatibility is crucial for maintaining the high performance and efficiency expected from these engines. The ECM’s advanced features allow for fine-tuned control, enhancing the overall operational effectiveness of the engines.

R2.8 CM2220 R101B

The R2.8 CM2220 R101B engine also benefits from the integration of the Cummins part 5258888 ECM. This ECM is tailored to work with the specific requirements of this engine model, ensuring that it operates at peak performance levels. The compatibility ensures that the ECM can handle the unique demands of the R2.8 CM2220 R101B engine, providing reliable and efficient control.

Role of Part 5258888 Electronic Control Module in Engine Systems

The part 5258888 Electronic Control Module (ECM) is integral to the operation and management of various engine systems. It serves as the central processing unit that oversees and regulates multiple engine functions to ensure optimal performance and efficiency.

Fuel Injection System

In the fuel injection system, the ECM 5258888 monitors inputs from sensors such as the Mass Air Flow (MAF) sensor, Oxygen (O2) sensor, and Manifold Absolute Pressure (MAP) sensor. It processes this data to determine the precise amount of fuel required for combustion. The ECM then sends signals to the fuel injectors, controlling the timing and duration of fuel delivery to achieve the desired air-fuel ratio.

Ignition System

For the ignition system, the ECM 5258888 calculates the optimal timing for spark plug firing. It receives data from the crankshaft position sensor and camshaft position sensor to synchronize the ignition timing with the engine’s rotational speed and piston position. This ensures efficient combustion and maximizes engine power output while minimizing emissions.

Emission Control System

In the emission control system, the ECM 5258888 plays a significant role in regulating emissions. It monitors the exhaust gas recirculation (EGR) valve, ensuring that the correct amount of exhaust gas is recirculated to reduce nitrogen oxides (NOx). Additionally, it controls the operation of the catalytic converter by adjusting the air-fuel mixture to maintain efficient catalytic conversion of harmful emissions.

Idle Control System

The ECM 5258888 manages the idle control system by adjusting the engine’s idle speed based on inputs from the throttle position sensor and engine coolant temperature sensor. It ensures a smooth and stable idle, which is essential for vehicle drivability and comfort.

Variable Valve Timing (VVT) System

In engines equipped with Variable Valve Timing, the ECM 5258888 adjusts the timing of the intake and exhaust valves to optimize engine performance across different operating conditions. It uses data from various sensors to determine the best valve timing for power, fuel efficiency, and emissions.

Turbocharger Control

For turbocharged engines, the ECM 5258888 regulates the turbocharger’s operation. It monitors boost pressure via the boost pressure sensor and adjusts the wastegate actuator to control the amount of boost delivered. This ensures that the engine receives the optimal amount of pressurized air for combustion, enhancing performance without risking engine damage.

Transmission Control

In vehicles with automatic transmissions, the ECM 5258888 works in conjunction with the Transmission Control Module (TCM) to manage gear shifts. It receives data from various sensors, including vehicle speed sensor and throttle position sensor, to determine the appropriate gear for the driving conditions, ensuring smooth and efficient transmission operation.

Battery and Charging System

The ECM 5258888 also monitors the battery and charging system. It receives inputs from the battery voltage sensor and alternator, ensuring that the battery is adequately charged and that the electrical system operates within specified parameters.

Overall, the ECM 5258888 is a sophisticated component that integrates and coordinates the functions of various engine systems to enhance performance, efficiency, and reliability.

Conclusion

The Cummins 5258888 Electronic Control Module is a critical component in the operation of commercial trucks, offering advanced features and benefits that enhance engine performance, fuel efficiency, and reliability. Its compatibility with various engine models and its role in managing complex engine functions make it an invaluable asset for fleet managers and truck operators. Proper installation, maintenance, and troubleshooting are essential to ensure the ECM operates effectively, contributing to a more efficient and environmentally compliant trucking operation.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.