5265234

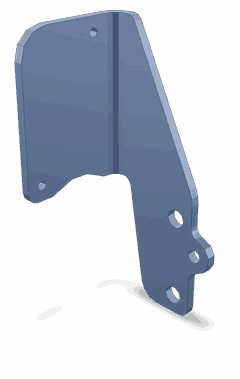

Electronic Control Module Bracket

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Electronic Control Module Bracket, identified by part number 5265234, is a component manufactured by Cummins, a leading name in the commercial truck industry. This part plays a significant role in the functionality and protection of the Electronic Control Module (ECM) in commercial trucks. Cummins, known for its robust and reliable engine solutions, ensures that this bracket is designed to meet the demanding requirements of heavy-duty applications.

Basic Concepts

The Electronic Control Module (ECM) is a vital component in modern trucks, responsible for managing various engine functions and ensuring optimal performance. The ECM requires a secure and stable mounting solution to operate effectively. The Electronic Control Module Bracket serves this purpose by providing a sturdy attachment point for the ECM, protecting it from physical damage and environmental factors.

Purpose and Functionality

The primary role of the Electronic Control Module Bracket is to maintain the ECM’s position and integrity within the truck’s engine compartment. By securely holding the ECM in place, the bracket ensures that the module remains stable during operation, which is crucial for consistent engine performance. Additionally, the bracket helps shield the ECM from vibrations, impacts, and harsh environmental conditions, contributing to the overall reliability of the truck’s electronic systems.

Key Features

The 5265234 Electronic Control Module Bracket is engineered with several key features that enhance its performance and durability. It is constructed from high-strength materials to withstand the rigors of heavy-duty use. The design includes precise mounting points and secure attachment mechanisms to ensure a stable fit. Additionally, the bracket may incorporate features such as vibration dampening elements and corrosion-resistant coatings to further protect the ECM.

Benefits

The use of the Electronic Control Module Bracket offers several benefits. It provides enhanced protection for the ECM, which is crucial for maintaining the truck’s electronic systems’ integrity. This protection contributes to improved truck performance and reliability, even in challenging operating conditions. The bracket’s durable construction and secure fit help ensure long-term stability and functionality of the ECM.

Installation Process

Proper installation of the Electronic Control Module Bracket is vital for ensuring optimal performance and longevity. The installation process involves several steps: First, the mounting location should be prepared by cleaning and, if necessary, reinforcing the surface. Next, the bracket should be aligned with the designated mounting points and secured using the provided fasteners. It is important to ensure that the bracket is firmly attached and that the ECM is properly seated within the bracket. Finally, all connections should be checked for security, and the system should be tested to confirm proper operation.

Troubleshooting and Maintenance

Regular maintenance and periodic inspections of the Electronic Control Module Bracket can help identify potential issues before they become significant problems. Common issues may include loose fasteners, corrosion, or physical damage to the bracket. If any issues are detected, they should be addressed promptly to prevent further damage to the ECM or the truck’s electronic systems. Maintenance tips include keeping the bracket and surrounding area clean, inspecting for signs of wear or damage, and ensuring all fasteners remain tight.

Safety Considerations

When working with the Electronic Control Module Bracket, it is important to observe several safety guidelines. Electrical safety is paramount, as the ECM and its connections carry electrical current. Ensure that the truck’s battery is disconnected before beginning any work on the ECM or bracket. Additionally, use appropriate personal protective equipment, such as gloves and safety glasses, to protect against potential hazards. Follow all manufacturer guidelines and recommendations for handling and installing the bracket to ensure a safe and effective installation.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the commercial truck industry. The company’s product range includes a variety of engines and components designed to meet the needs of heavy-duty applications, ensuring that commercial trucks operate efficiently and reliably. Cummins’ commitment to excellence is reflected in its extensive portfolio of high-performance parts and components, including the 5265234 Electronic Control Module Bracket.

Electronic Control Module Bracket (Part 5265234) Compatibility with Cummins Engines

The Electronic Control Module (ECM) Bracket, identified by part number 5265234, is a critical component in the installation and operation of the ECM within various Cummins engine models. This bracket ensures the ECM is securely mounted, providing stability and protection for the sensitive electronic components it houses.

ISB6.7 CM2250 and ISB6.7 CM2350 B101

The ECM Bracket 5265234 is specifically designed to fit the ISB6.7 CM2250 and ISB6.7 CM2350 B101 engines. These engines are part of the Cummins ISB series, known for their robust performance and reliability in various applications, including heavy-duty trucks and industrial machinery.

The bracket’s design allows for precise alignment and secure attachment of the ECM, ensuring that the module is positioned correctly relative to other engine components. This is crucial for maintaining optimal performance and preventing potential damage from vibrations or misalignment.

Installation and Functionality

During installation, the ECM Bracket 5265234 is mounted to the engine block using specified fasteners. This mounting process is critical to ensure that the ECM is held firmly in place, reducing the risk of movement that could lead to electrical issues or damage to the module.

The bracket’s role extends beyond mere support; it also aids in the management of electrical connections and cooling airflow around the ECM. Proper airflow is essential for maintaining the ECM’s operating temperature within safe limits, which in turn affects the overall reliability and longevity of the engine’s electronic control systems.

Importance of Compatibility

Ensuring that the ECM Bracket 5265234 is compatible with the ISB6.7 CM2250 and ISB6.7 CM2350 B101 engines is vital for maintaining the integrity of the engine’s electronic systems. Using the correct bracket guarantees that the ECM is installed correctly, which is essential for the engine’s performance and the prevention of potential failures.

Role of Part 5265234 Electronic Control Module Bracket in Engine Systems

The Electronic Control Module (ECM) Bracket, identified by part number 5265234, serves as a foundational component in the orchestration of various engine systems. This bracket securely mounts the ECM, ensuring it remains stable and protected within the engine compartment.

In conjunction with the Nitrogen Oxide (NOx) Sensor, the ECM Bracket facilitates the precise monitoring and regulation of nitrogen oxide emissions. The NOx Sensor feeds real-time data to the ECM, which then adjusts fuel injection and ignition timing to minimize emissions. The stable mounting provided by the bracket is essential for the accurate functioning of the ECM, thereby ensuring the sensor’s data is processed correctly.

Additionally, the ECM Bracket supports the integration of various other sensors within the engine system. These sensors collect data on parameters such as air-fuel ratio, engine temperature, and manifold pressure. The ECM processes this data to optimize engine performance, fuel efficiency, and emissions control.

The reliable placement of the ECM, courtesy of the bracket, allows for consistent communication between the ECM and these sensors, leading to enhanced engine management and overall vehicle performance.

Conclusion

The 5265234 Electronic Control Module Bracket is a critical component in the operation and protection of the ECM in Cummins engines. Its robust design, precise mounting capabilities, and compatibility with specific engine models ensure that the ECM remains stable and protected, contributing to the overall reliability and performance of the engine. Regular maintenance and proper installation are essential to maximize the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.