This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

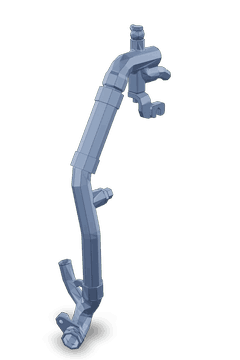

The Exhaust Cooler Water Outlet Tube, identified by part number 5311245, is a component manufactured by Cummins, a prominent name in the heavy-duty truck engine industry. This tube is integral to the operation of heavy-duty truck engines, particularly within the exhaust gas recirculation (EGR) cooling system. Cummins, known for its commitment to quality and innovation, designs this part to enhance engine performance and efficiency 1.

Function and Operation

The Exhaust Cooler Water Outlet Tube operates as a conduit within the EGR cooling system. Its primary role is to direct the flow of coolant, which is crucial for regulating the temperature of exhaust gases before they are recirculated back into the engine. By maintaining optimal exhaust gas temperatures, the tube contributes to the efficient operation of the EGR system, which is designed to reduce nitrogen oxide emissions and improve fuel efficiency 2.

Key Features

The design and construction of the Exhaust Cooler Water Outlet Tube are tailored for performance and durability. It is typically made from high-quality materials that can withstand the harsh conditions within an engine compartment. The tube features secure connection types, ensuring a reliable seal and efficient coolant flow. Unique design elements may include reinforced sections to handle high pressure and temperature variations, enhancing its longevity and effectiveness in the EGR system 3.

Benefits

Incorporating the Exhaust Cooler Water Outlet Tube into the EGR system offers several advantages. It contributes to improved engine efficiency by ensuring that the EGR system operates within its optimal temperature range. This, in turn, can lead to reduced emissions, aligning with environmental regulations. Additionally, the tube’s robust design enhances the durability of EGR system components, potentially reducing maintenance needs and extending the overall lifespan of the engine 4.

Installation and Integration

Proper installation of the Exhaust Cooler Water Outlet Tube is vital for the effective operation of the EGR system. Installation guidelines typically include ensuring the system is free of debris and that all connections are secure to prevent coolant leaks. Preparatory steps may involve inspecting the EGR system for any signs of wear or damage that could affect the tube’s performance 5.

Maintenance and Troubleshooting

Routine maintenance of the Exhaust Cooler Water Outlet Tube is recommended to ensure its optimal performance. This may include regular inspections for signs of wear, corrosion, or leaks. Common issues that may arise include blockages within the tube or connection failures. Troubleshooting steps can involve cleaning the tube, checking connections for tightness, and replacing the tube if significant wear or damage is detected 6.

Conclusion

The Exhaust Cooler Water Outlet Tube (part number 5311245) plays a significant role in the efficient operation of heavy-duty truck engines by ensuring optimal coolant flow within the EGR system. Its design and construction are tailored for durability and performance, contributing to engine efficiency, reduced emissions, and extended engine lifespan. Proper installation, maintenance, and troubleshooting are essential for maximizing the benefits of this Cummins part.

-

Hiereth, H., Prenninger, P., & Drexl, K. W. (2010). Charging the Internal Combustion Engine. Springer.

↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Wright, G. (2015). Fundamentals of Medium-Heavy Duty Diesel Engines. Jones & Bartlett Learning.

↩ -

Cummins Inc. (n.d.). Service Manual (4388668) for QSB6.7 CM2350 B130 engine.

↩ -

Cummins Inc. (n.d.). Service Manual (4388668) for QSB6.7 CM2350 B130 engine.

↩ -

Cummins Inc. (n.d.). Service Manual (4388668) for QSB6.7 CM2350 B130 engine.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.