This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

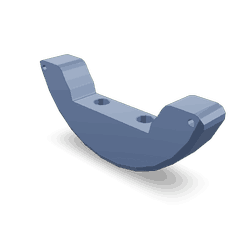

The Cummins 3176216 Crankshaft Counterweight is a component designed to enhance the performance and reliability of heavy-duty truck engines. Its primary role is to contribute to the balance and stability of the engine’s crankshaft, which is vital for the smooth operation of the vehicle 1.

Basic Concepts of Crankshaft Counterweights

A crankshaft counterweight is a mass attached to the crankshaft of an engine. Its function is to counterbalance the forces generated by the pistons as they move up and down. This counterbalancing helps maintain the engine’s balance, reducing vibrations and ensuring smoother operation 2. The importance of crankshaft counterweights lies in their ability to mitigate the effects of these forces, which can otherwise lead to increased wear on engine components and decreased efficiency.

Purpose of the 3176216 Crankshaft Counterweight

The Cummins 3176216 Crankshaft Counterweight plays a specific role in the operation of a truck engine. It is designed to provide precise balancing for the crankshaft, which is particularly important in heavy-duty applications where the engine operates under significant stress. By maintaining balance, the counterweight contributes to the engine’s overall performance, ensuring that it runs smoothly and efficiently 3.

Key Features

The Cummins 3176216 Crankshaft Counterweight is characterized by its robust design and high-quality material composition. It is engineered to withstand the demanding conditions of heavy-duty truck engines. The counterweight is typically made from a durable alloy that offers excellent resistance to wear and fatigue. Its design ensures optimal balance and integration with the crankshaft, enhancing the engine’s performance 4.

Benefits

The benefits of using the Cummins 3176216 Crankshaft Counterweight include improved engine smoothness, reduced wear on engine components, and enhanced overall engine efficiency. By maintaining balance, the counterweight helps to minimize vibrations, which can lead to premature wear and reduced engine lifespan. Additionally, a well-balanced engine operates more efficiently, contributing to better fuel economy and overall performance.

Installation Process

Proper installation of the Cummins 3176216 Crankshaft Counterweight involves several steps. First, ensure that the crankshaft is clean and free of any debris. The counterweight should be aligned correctly with the crankshaft before being secured in place. It is important to use the appropriate tools and follow the manufacturer’s guidelines to ensure a proper fit and secure attachment. After installation, it is advisable to perform a test run to confirm that the engine operates smoothly and that the counterweight is functioning as intended.

Troubleshooting Common Issues

Common issues with crankshaft counterweights may include imbalance or wear. If an engine exhibits unusual vibrations or noise, it may indicate a problem with the counterweight. Troubleshooting steps include inspecting the counterweight for signs of wear or damage, ensuring it is properly aligned and secured, and checking for any other potential sources of imbalance within the engine. Addressing these issues promptly can help maintain engine performance and longevity.

Maintenance Tips

Regular maintenance practices are important to ensure the longevity and optimal performance of the Cummins 3176216 Crankshaft Counterweight. This includes periodic inspection for signs of wear or damage, ensuring that it remains properly aligned and secured, and cleaning the component as necessary. Following the manufacturer’s recommended maintenance schedule will help to identify and address any potential issues before they lead to more significant problems.

Cummins Overview

Cummins Inc. is a global leader in the design, manufacture, and distribution of engines and related technologies. With a history spanning over a century, Cummins has established a strong reputation for producing high-quality, reliable components for a wide range of applications, including heavy-duty trucks. The company’s product range includes engines, filtration systems, and power generation equipment, all designed to meet the demanding needs of various industries. Cummins’ commitment to innovation and excellence has made it a trusted name in the automotive industry.

Crankshaft Counterweight 3176216 Compatibility with Cummins Engines

The Crankshaft Counterweight part number 3176216, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is crucial for maintaining the balance and smooth operation of the crankshaft, ensuring that the engine runs efficiently and reliably.

GTA38 G CMEICS G116C

The Crankshaft Counterweight 3176216 is compatible with the GTA38 G CMEICS G116C engine. This compatibility ensures that the counterweight provides the necessary balance to the crankshaft, reducing vibrations and enhancing the engine’s performance.

K38, K50, KTA38GC CM558, QSK38 CM2150 MCRS, QSK38 CM850 MCRS

The part 3176216 is also suitable for the K38, K50, KTA38GC CM558, QSK38 CM2150 MCRS, and QSK38 CM850 MCRS engines. These engines benefit from the counterweight’s ability to maintain crankshaft balance, which is essential for the smooth operation of these models.

QSK50 CM2150 K107, QSK50 CM2150 MCRS, QSK50 CM2350 K108

Lastly, the Crankshaft Counterweight 3176216 fits the QSK50 CM2150 K107, QSK50 CM2150 MCRS, and QSK50 CM2350 K108 engines. This compatibility ensures that the counterweight provides the necessary balance to the crankshaft, reducing vibrations and enhancing the engine’s performance across these models.

Role of Part 3176216 Crankshaft Counterweight in Engine Systems

The part 3176216 Crankshaft Counterweight is integral to the balanced operation of various engine systems. When integrated into the Assembly Crankshaft, it helps mitigate the rotational forces generated by the crankshaft, ensuring smoother operation and reduced wear on the Assembly Cylinder Block.

In the context of the Assy, Short Block K50G3, the counterweight plays a significant role in maintaining the equilibrium of the rotating assembly, which is essential for the longevity and efficiency of the Base Parts and Block.

For the Cylinder and Crank and Gear Assembly, the counterweight ensures that the forces are evenly distributed, which is vital for the precise functioning of the Crankshaft and its associated components.

When considering the Engine as a whole, the counterweight is a key element in the Crankshaft and Gear system, contributing to the stability of the Crankshaft and Gears.

In the Crankshaft Assembly, it works in tandem with other components to provide a harmonious balance, which is necessary for the optimal performance of the Cylinder Block and Cylinder Block Assembly.

The EBM-Block benefits from the counterweight by experiencing less vibration and stress, which translates to enhanced durability.

Within the Engine Assembly Crankshaft and Engine Crankshaft, the counterweight is essential for maintaining the dynamic balance, which is fundamental for the reliable operation of the Long Block Assy. - 50.

In the Short Block Assembly and its variants like the Short Block Assembly - 50, Short Block Assy -K38, and Short Block Assy -K50, the counterweight ensures that the crankshaft’s motion is as smooth and balanced as possible, which is imperative for the overall health and performance of the engine.

Conclusion

The Cummins 3176216 Crankshaft Counterweight is a critical component for maintaining the balance and efficiency of heavy-duty truck engines. Its robust design and high-quality materials ensure durability and performance under demanding conditions. Proper installation, regular maintenance, and prompt troubleshooting of issues are essential for maximizing the benefits of this Cummins part.

-

Trzesniowski, Michael. The Complete Vehicle. Springer Nature, 2023.

↩ -

Reif, Konrad. Gasoline Engine Management Systems and Components. Springer Vieweg, 2015.

↩ -

Garrett, TK, Newton, K, Steeds, W. The Motor Vehicle. Reed Educational and Professional Publishing Ltd, 2001.

↩ -

Boyce, Meherwan P. Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing, 2002.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.