This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

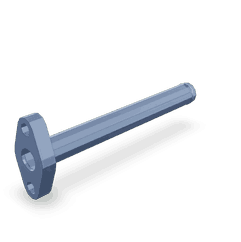

The Tur Oil Drain Tube, part number 3200178, is a component manufactured by Cummins, a prominent figure in the automotive and heavy-duty truck industry. This tube is designed to facilitate the oil drainage process in heavy-duty trucks, contributing to the maintenance and longevity of truck engines. Cummins, known for its commitment to quality and innovation, produces this part to meet the demanding requirements of heavy-duty applications 1.

Function and Operation

This Cummins part is integral to the oil drainage system of a truck engine. It allows for the efficient removal of used oil from the engine, a necessary step in regular maintenance routines. The tube is designed to connect to the oil pan, providing a pathway for oil to flow out during the drainage process. Its role is to ensure that oil is drained completely and efficiently, minimizing the risk of oil residue that could contaminate new oil and affect engine performance 2.

Key Features

The Tur Oil Drain Tube is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials that are resistant to corrosion and wear, ensuring longevity even in harsh operating conditions. The design of the tube includes a secure fitting mechanism that ensures a tight seal, preventing leaks during operation. Additionally, the tube is engineered to withstand high temperatures and pressures, making it suitable for heavy-duty applications 3.

Benefits of Using the Tur Oil Drain Tube

Incorporating the Tur Oil Drain Tube into the maintenance routine of a heavy-duty truck offers several advantages. It contributes to more efficient oil changes by ensuring complete drainage of used oil. This efficiency can reduce maintenance time and improve the overall maintenance process. Furthermore, by facilitating thorough oil changes, the tube plays a part in promoting engine longevity, as clean oil is crucial for optimal engine performance and protection.

Installation Process

Installing the Tur Oil Drain Tube requires following a series of steps to ensure proper fitting and functionality. The process involves securing the tube to the oil pan using the provided fittings, ensuring a tight and leak-proof connection. It is important to use the recommended tools for installation and to observe safety precautions, such as ensuring the engine is cool and the vehicle is securely supported.

Maintenance and Care

To ensure the longevity and optimal performance of the Tur Oil Drain Tube, regular maintenance and care are recommended. This includes inspecting the tube for signs of wear or damage before each use and cleaning it thoroughly after each oil change. If any issues are detected, such as cracks or leaks, the tube should be replaced to maintain the integrity of the oil drainage system.

Troubleshooting Common Issues

Common issues associated with the Tur Oil Drain Tube may include leaks or blockages. These can often be addressed through regular maintenance and inspection. If a leak is detected, it may be necessary to tighten the fittings or replace the tube. Blockages can usually be cleared by ensuring the tube is free from debris and is properly aligned with the oil pan.

Environmental and Safety Considerations

Proper oil drainage is not only important for engine maintenance but also for environmental protection. The Tur Oil Drain Tube plays a role in facilitating safe and environmentally friendly oil changes by ensuring that used oil is completely and efficiently drained from the engine. When handling and disposing of used oil, it is important to observe safety measures and environmental regulations to prevent contamination and ensure responsible disposal.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history of innovation and a commitment to quality, Cummins has established a strong reputation in the automotive and heavy-duty truck industry. The company’s product range is designed to meet the needs of various applications, emphasizing reliability, performance, and customer satisfaction.

Compatibility of 3200178 with Cummins Engines

The Tur Oil Drain Tube, part number 3200178, is compatible with various Cummins engines, including the K19 and NH/NT 855 engines, as well as the QSK19 CM500 and QSK19 CM850 MCRS engines. This part is engineered to ensure efficient oil flow and prevent the accumulation of contaminants, thereby maintaining optimal engine performance.

Role of 3200178 in Engine Systems

The Tur Oil Drain Tube is an essential component in the arrangement and operation of turbocharged engine systems. This component is specifically designed to facilitate the drainage of oil from the turbocharger, ensuring that the lubrication system remains efficient and that the turbocharger operates within optimal parameters.

In the context of turbocharger mounting, the Tur Oil Drain Tube is strategically positioned to connect the oil drain port of the turbocharger to the engine’s oil return system. This connection is vital for maintaining the integrity of the lubrication circuit, as it allows for the continuous circulation of oil, which is necessary for the cooling and lubrication of the turbocharger’s rotating components.

The integration of the Tur Oil Drain Tube within the turbocharger plumbing system ensures that any excess oil that has lubricated the turbocharger’s bearings and other moving parts is efficiently returned to the engine’s oil sump. This process is important for preventing oil buildup within the turbocharger, which could lead to performance issues or component failure.

Furthermore, the Tur Oil Drain Tube plays a role in the overall turbocharger location within the engine bay. Its design and placement must account for the spatial constraints and the thermal environment of the turbocharger. The tube must be routed in a manner that avoids contact with high-temperature components and ensures that it can withstand the operational stresses of the engine.

Conclusion

The Tur Oil Drain Tube, part number 3200178, is a critical component for maintaining the efficiency and reliability of heavy-duty truck engines. Its proper installation and maintenance are important for the turbocharger’s longevity and the engine’s overall efficiency. Regular inspection, cleaning, and replacement when necessary ensure that the oil drainage system operates effectively, contributing to the sustained performance and reliability of turbocharged engines.

-

Reif, K. (Ed.). (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Reif, K. (Ed.). (2014). Diesel Engine Management Systems and Components. Springer Vieweg.

↩ -

Reif, K. (2014). Diesel Engine Management Systems and Components. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.