This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

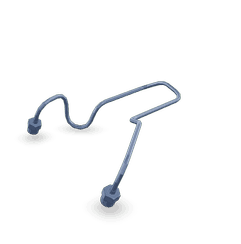

The Cummins Injector Fuel Supply Tube, identified by Part #3930391, is a critical component in the fuel delivery system of heavy-duty trucks. Manufactured by Cummins, a renowned name in the automotive and heavy-duty truck industries, this tube is essential for the efficient delivery of fuel to the injectors, ensuring the smooth operation and performance of the vehicle’s engine 1.

Function and Operation

The Injector Fuel Supply Tube operates as a conduit within the fuel system, responsible for delivering fuel from the fuel tank to the injectors. It maintains a consistent fuel pressure, which is essential for the injectors to function correctly. The tube’s design allows it to withstand the high pressures and temperatures inherent in diesel fuel systems, ensuring reliable fuel delivery under various operating conditions 2.

Purpose of the Injector Fuel Supply Tube

The Injector Fuel Supply Tube (Part #3930391) ensures that fuel is delivered to the injectors in a controlled and consistent manner. This consistent fuel delivery is fundamental to achieving optimal fuel efficiency and engine performance. By maintaining precise fuel pressure, the tube helps in reducing fuel wastage and enhancing the overall efficiency of the engine 3.

Key Features

The Injector Fuel Supply Tube is constructed from durable materials, designed to resist corrosion and wear, ensuring longevity and reliability. Its design specifications include precise dimensions and fittings that ensure a secure connection within the fuel system. Unique attributes such as reinforced sections and specialized coatings enhance its functionality, providing resistance against the harsh conditions within a diesel engine’s fuel system 4.

Benefits

The advantages of the Injector Fuel Supply Tube include improved fuel delivery, which directly impacts engine performance. By ensuring a steady supply of fuel under pressure, the tube contributes to more efficient combustion, potentially increasing fuel efficiency. Additionally, its robust construction and design enhance the reliability of the fuel system, reducing the likelihood of fuel leaks or pressure inconsistencies 1.

Installation and Compatibility

Proper installation of the Injector Fuel Supply Tube is crucial for its effective operation. It requires careful alignment and secure fitting within the fuel system to ensure there are no leaks and that fuel pressure is maintained. Specific requirements or considerations may vary depending on the truck model, necessitating adherence to manufacturer guidelines for compatibility and installation procedures 2.

Maintenance and Troubleshooting

Routine maintenance of the Injector Fuel Supply Tube involves checking for signs of wear, corrosion, or leaks. Regular inspections can help identify potential issues such as clogs or pressure inconsistencies before they lead to more significant problems. Troubleshooting common issues may involve cleaning or replacing the tube if it shows signs of damage or failure 3.

Safety Considerations

When working with the Injector Fuel Supply Tube, it is important to observe safety protocols and precautions. This includes handling the fuel system with care to avoid spills or leaks, and adhering to manufacturer guidelines for maintenance and repair. Proper ventilation and the use of protective equipment are recommended when working with fuel systems to ensure safety 4.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability within the automotive and heavy-duty truck industries. Its product offerings are designed to meet the demanding requirements of various applications, ensuring optimal performance and efficiency.

Cummins Injector Fuel Supply Tube (Part 3930391)

The Cummins Injector Fuel Supply Tube, identified by the part number 3930391, is a critical component in the fuel delivery system of several Cummins engines. This part ensures that fuel is efficiently and accurately delivered to the injectors, which is essential for maintaining optimal engine performance and fuel efficiency.

Application in Cummins Engines

-

6C8.3 Engine Series: The 3930391 injector fuel supply tube is specifically designed to fit within the 6C8.3 engine series. This engine series is known for its robust construction and reliability, making it a popular choice in various industrial and commercial applications. The fuel supply tube in this context plays a pivotal role in maintaining the engine’s performance by ensuring that the injectors receive the correct amount of fuel under varying operating conditions.

-

Other Cummins Engines: While the primary focus here is on the 6C8.3 engine series, it is worth noting that the 3930391 injector fuel supply tube is also compatible with other Cummins engines. This versatility underscores the importance of this component across different engine models, highlighting its critical function in the overall fuel delivery system.

The design and material of the 3930391 injector fuel supply tube are engineered to withstand the high pressures and temperatures inherent in diesel engines. This ensures longevity and reliability, reducing the likelihood of fuel leaks and other issues that could compromise engine performance 1.

Role of Part 3930391 Injector Fuel Supply Tube in Engine Systems

The Injector Fuel Supply Tube (Part 3930391) is an integral component in the fuel delivery system of an engine. It serves as a conduit that facilitates the transfer of fuel from the fuel rail to the individual fuel injectors. This part ensures a consistent and regulated flow of fuel, which is essential for the precise operation of the injectors 2.

Integration with Injector Plumbing

The Injector Fuel Supply Tube is a key element in the injector plumbing system. It connects the fuel rail to each injector, allowing for the distribution of fuel under pressure. The tube must be correctly aligned and sealed to prevent any fuel leaks, which could lead to inefficient engine performance or safety hazards 3.

Interaction with Fuel Rail

The fuel rail is a pressurized manifold that supplies fuel to each injector. The Injector Fuel Supply Tube extends from the fuel rail to each injector nozzle. This setup ensures that each injector receives an equal amount of fuel, which is vital for balanced combustion across all cylinders 4.

Role in Fuel Delivery

In the fuel delivery system, the Injector Fuel Supply Tube plays a significant role in maintaining the integrity of the fuel path. It must withstand the high pressures and temperatures within the fuel system while ensuring a smooth and uninterrupted flow of fuel to the injectors 1.

Connection to Injectors

Each Injector Fuel Supply Tube is directly connected to an injector. The tube’s design allows it to fit snugly into the injector port, creating a secure connection that resists vibrations and movements that occur during engine operation. This connection is fundamental for the injectors to function correctly, as they rely on a steady supply of fuel to atomize and inject into the combustion chamber 2.

Importance in Plumbing System

Within the overall plumbing system of the engine, the Injector Fuel Supply Tube is a vital link. It is part of a network that includes the fuel pump, fuel filter, fuel rail, and injectors. The tube’s role in this network is to provide a dedicated pathway for fuel, ensuring that each injector operates within the parameters set by the engine’s electronic control unit (ECU) 3.

Conclusion

In summary, the Injector Fuel Supply Tube (Part 3930391) is a component that ensures the efficient and reliable delivery of fuel to the injectors, which is essential for the optimal performance of the engine. Its proper function and maintenance are key to the overall health and efficiency of the fuel system 4.

-

Dempsey, P. (2008). Troubleshooting and Repairing Diesel Engines. McGraw-Hill.

↩ ↩ ↩ ↩ -

Reif, K. (2015). Gasoline Engine Management Systems and Components. Springer Vieweg.

↩ ↩ ↩ ↩ -

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg.

↩ ↩ ↩ ↩ -

Halderman, J. D. (2012). Automotive Principles: Diagnosis and Service. Prentice Hall.

↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.