This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3408568 Pressure Sensor is a component designed to monitor and report pressure levels within the systems of commercial trucks. Its purpose is to provide accurate pressure readings that are crucial for the proper functioning of various truck systems. The significance of this sensor lies in its ability to ensure that the truck operates efficiently and safely by maintaining optimal pressure levels in critical systems 3.

Basic Concepts of Pressure Sensors

Pressure sensors are devices that measure the force exerted by a fluid (liquid or gas) on a surface. They convert this physical pressure into an electrical signal, which can then be interpreted by the vehicle’s electronic systems. In automotive applications, pressure sensors are used in various systems, including fuel injection, brake systems, and engine management. They play a role in ensuring that these systems operate within their designed parameters by providing real-time data on pressure levels 1.

Role of the 3408568 Pressure Sensor in Truck Operation

The Cummins 3408568 Pressure Sensor is integrated into the truck’s systems to monitor specific pressure points. It provides data that is used by the truck’s electronic control unit (ECU) to make adjustments to the system as needed. This sensor plays a role in maintaining the efficiency and reliability of the truck’s systems by ensuring that pressure levels are maintained within the required range. The data from this sensor is vital for the ECU to make informed decisions that affect the truck’s performance and safety 3.

Key Features

The Cummins 3408568 Pressure Sensor is characterized by its robust design and the use of high-quality materials that ensure durability and reliability in demanding environments. It incorporates advanced technology that allows for precise pressure measurements. The sensor is designed to withstand the harsh conditions typically encountered in commercial truck operations, ensuring long-term performance and reliability 2.

Benefits of Using the 3408568 Pressure Sensor

The use of the Cummins 3408568 Pressure Sensor offers several advantages. It contributes to improved performance by ensuring that the truck’s systems operate at optimal pressure levels. This can lead to enhanced fuel efficiency and reduced wear on components. Additionally, by providing accurate pressure data, the sensor plays a role in enhancing the safety of truck operations by helping to prevent system failures that could arise from incorrect pressure levels 3.

Installation and Integration

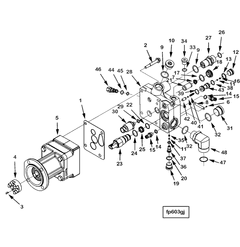

Installing the Cummins 3408568 Pressure Sensor involves connecting it to the appropriate pressure points within the truck’s systems and ensuring it is properly integrated with the ECU. This process requires careful attention to detail to ensure that the sensor is correctly positioned and that all connections are secure. Proper installation is important for the sensor to function effectively and provide accurate data 1.

Troubleshooting and Maintenance

Common issues with the Cummins 3408568 Pressure Sensor may include inaccurate readings or sensor failure. Troubleshooting steps involve checking the sensor’s connections, ensuring it is correctly installed, and verifying that it is compatible with the truck’s systems. Regular maintenance practices, such as inspecting the sensor for signs of wear or damage and ensuring that its connections remain secure, can help to ensure optimal performance 2.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicle operations. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name in the industry 3.

Cummins Pressure Sensor 3408568 in Engine Applications

The Cummins Pressure Sensor 3408568 is a critical component in various Cummins engine models, ensuring optimal performance and efficiency. This sensor is integral to the engine’s operation, providing essential data for the engine control unit (ECU) to manage fuel injection, timing, and other vital functions.

QSK78 Series

In the QSK78 series, the Pressure Sensor 3408568 plays a pivotal role in maintaining the engine’s performance. This series is known for its robust design and high power output, making it suitable for heavy-duty applications such as marine and industrial use. The sensor’s accurate readings help in fine-tuning the engine’s operations, ensuring it runs smoothly under various load conditions 3.

CM500 Series

The CM500 series engines also benefit significantly from the Pressure Sensor 3408568. These engines are typically used in construction equipment and agricultural machinery, where reliability and performance are paramount. The sensor’s precise pressure measurements are crucial for the ECU to adjust fuel delivery and timing, enhancing the engine’s efficiency and longevity 1.

Integration and Functionality

The Pressure Sensor 3408568 is designed to integrate seamlessly with the engine’s electronic control systems. It is typically mounted in a location that allows it to accurately measure the pressure within the engine’s system. The sensor communicates with the ECU through a standardized electrical connection, ensuring that the data is transmitted without loss or interference.

The sensor’s role in the engine’s operation is multifaceted. It helps in monitoring the pressure within the fuel system, ensuring that the fuel is delivered at the correct pressure for optimal combustion. Additionally, it aids in managing the engine’s boost pressure, which is crucial for maintaining performance in turbocharged engines 2.

Reliability and Maintenance

The Pressure Sensor 3408568 is built to withstand the harsh conditions of engine operation. It is designed to be durable and resistant to wear and tear, ensuring a long service life. Regular maintenance checks are recommended to ensure the sensor remains in good working condition. Any signs of malfunction or degradation should be addressed promptly to prevent potential engine issues 3.

Role of Part 3408568 Pressure Sensor in Engine Systems

The Part 3408568 Pressure Sensor is integral to the efficient operation of several key engine components, ensuring optimal performance and reliability.

Integration with the Fuel Pump

The fuel pump is responsible for delivering fuel from the tank to the engine at the required pressure. The Part 3408568 Pressure Sensor monitors the fuel pressure within the system. By providing real-time data on fuel pressure, this sensor allows the engine control unit (ECU) to make necessary adjustments to the fuel pump’s operation. This ensures that the fuel is delivered at the precise pressure needed for combustion, enhancing engine efficiency and performance 1.

Collaboration with the Pressure Regulator Valve

The pressure regulator valve maintains consistent fuel pressure within the fuel rail, which is essential for stable engine operation. The Part 3408568 Pressure Sensor feeds pressure data to the ECU, which then modulates the pressure regulator valve. This dynamic interaction ensures that the fuel pressure remains within the optimal range, preventing issues such as fuel starvation or over-pressurization. Consistent fuel pressure leads to smoother engine operation and improved fuel economy 2.

Conclusion

In summary, the Cummins 3408568 Pressure Sensor plays a significant role in the coordination between the fuel pump and the pressure regulator valve, contributing to the overall efficiency and reliability of the engine system. Its accurate pressure readings are essential for the engine’s efficient operation and longevity 3.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.