This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Compressor Water Outlet Tube, identified by Part #3655314, is a component manufactured by Cummins, a leading name in the production of diesel engines and related technologies. This tube is integral to the operation of heavy-duty truck systems, facilitating the efficient management of water flow within the engine’s cooling system. Cummins is renowned for its commitment to quality and innovation in the automotive industry, ensuring that components like the Compressor Water Outlet Tube meet rigorous standards for performance and reliability 1.

Function and Operation

The Compressor Water Outlet Tube operates by directing the flow of water from the compressor to other parts of the truck’s cooling system. This process is vital for maintaining the optimal temperature of the engine, ensuring that it functions efficiently under various operating conditions. The tube’s design allows for a controlled and consistent flow of water, which is crucial for the overall performance and longevity of the engine 2.

Purpose of the Compressor Water Outlet Tube

The primary role of the Compressor Water Outlet Tube in a truck’s operation is to contribute to the cooling system’s effectiveness. By ensuring that water is efficiently circulated through the engine, the tube helps to prevent overheating, which can lead to significant engine damage. Additionally, its proper function supports overall engine performance, allowing the truck to operate more reliably and efficiently 3.

Key Features

The Compressor Water Outlet Tube is characterized by several key features that enhance its functionality. These include a durable material composition designed to withstand the high pressures and temperatures of the engine cooling system. Its design elements are tailored to ensure a secure fit and efficient water flow, contributing to the tube’s reliability and performance.

Benefits

The use of the Compressor Water Outlet Tube offers several advantages. It contributes to improved system reliability by ensuring efficient water flow and temperature management within the engine. Enhanced performance is another benefit, as the tube’s role in the cooling system directly impacts the engine’s ability to operate under various conditions. Additionally, by supporting the engine’s efficiency and longevity, the tube can lead to potential cost savings for fleet operators through reduced maintenance and replacement costs.

Installation and Compatibility

Proper installation of the Compressor Water Outlet Tube is crucial for ensuring optimal performance and compatibility with various truck models. Guidelines for installation should be followed closely, including any specific requirements or considerations for securing the tube in place and ensuring it is correctly aligned with the cooling system’s components.

Maintenance and Troubleshooting

Routine maintenance practices are recommended to prolong the lifespan of the Compressor Water Outlet Tube. These may include regular inspections for signs of wear or damage, ensuring that connections are secure, and that the tube is free from obstructions. Troubleshooting common issues, such as leaks or inefficient water flow, can often be addressed through these maintenance practices, ensuring the tube continues to operate effectively.

Safety Considerations

When working with the Compressor Water Outlet Tube, it is important to observe safety protocols and precautions. This includes ensuring that the engine is cool before beginning any work, using appropriate personal protective equipment, and following manufacturer guidelines for handling and installation. These measures help to ensure the well-being of mechanics and operators.

Environmental Impact

The use of the Compressor Water Outlet Tube, like all components in truck manufacturing, has environmental implications. Cummins is committed to minimizing its ecological footprint and promoting sustainability in its manufacturing processes. Efforts may include the use of recyclable materials, reducing waste in production, and designing components that contribute to the overall efficiency and reduced emissions of the vehicles they are part of.

Cummins Overview

Cummins, the manufacturer of the Compressor Water Outlet Tube, has a long-standing reputation in the industry for innovation and quality. With a history of producing reliable and efficient diesel engines and components, Cummins continues to lead in the development of technologies that enhance the performance and sustainability of heavy-duty trucks. Its commitment to quality is evident in every component it produces, including the Compressor Water Outlet Tube.

Compatibility with Cummins Engines

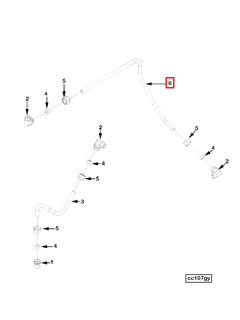

The Compressor Water Outlet Tube, identified by part number 3655314 and manufactured by Cummins, is a critical component in the cooling system of certain engine models. This part is designed to facilitate the flow of water from the compressor to the radiator, ensuring efficient heat dissipation and maintaining optimal engine temperature.

NH/NT 855 Engines

The NH/NT 855 engines are part of the Cummins engine family that benefit from the precise engineering of the 3655314 Compressor Water Outlet Tube. This part is integral to the cooling system of these engines, ensuring that the water circulated through the compressor is effectively directed to the radiator. The compatibility of this part with the NH/NT 855 engines underscores its importance in maintaining the engine’s performance and longevity.

The 3655314 Compressor Water Outlet Tube is engineered to fit seamlessly with the NH/NT 855 engines, providing a reliable connection between the compressor and the radiator. This ensures that the cooling system operates efficiently, preventing overheating and maintaining the engine’s operational efficiency. The use of this part in these engines highlights Cummins’ commitment to quality and reliability in their engine components.

Role of the Compressor Water Outlet Tube in Engine Systems

In the intricate arrangement of an engine system, the Compressor Water Outlet Tube (part 3655314) serves a significant function in maintaining the optimal performance and longevity of the compressor. This component is integral to the compressor coolant system, ensuring that the compressor operates within safe temperature ranges.

The Compressor Water Outlet Tube is designed to facilitate the efficient flow of coolant from the compressor to other parts of the engine system. This tube is a vital link in the coolant circulation path, which begins at the compressor where heat is generated due to the compression of air or gas. The coolant absorbs this heat, and the Compressor Water Outlet Tube directs it away from the compressor, preventing overheating.

In conjunction with the compressor coolant system, the tube ensures that the coolant is evenly distributed. This even distribution is essential for dissipating heat effectively across the compressor and other engine components. The tube’s placement and design are engineered to minimize resistance and maximize flow, which is paramount for the compressor’s efficiency and reliability.

Furthermore, the Compressor Water Outlet Tube interacts with other components within the coolant system, such as the radiator and thermostat, to maintain a consistent coolant temperature. This interaction is vital for the overall thermal management of the engine, as it helps to stabilize the operating temperature of the compressor and other heat-generating parts.

Conclusion

In summary, the Compressor Water Outlet Tube (part 3655314) is a key component in the engine’s coolant system, playing a pivotal role in the thermal management of the compressor. Its proper function ensures that the compressor remains cool and operates efficiently, contributing to the engine’s overall performance and durability. Cummins’ commitment to quality and innovation is evident in the design and functionality of this part, ensuring that it meets the rigorous demands of heavy-duty truck engines.

-

Reif, Konrad Ed. Gasoline Engine Management Systems and Components. Springer Vieweg, 2015.

↩ -

Genta, Giancarlo, and Lorenzo Morello. The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer, 2019.

↩ -

Robinson, Alan, and Andrew Livesey. The Repair of Vehicle Bodies Fifth Edition. Elsevier, 2006.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.