This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

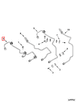

Fuel supply systems are critical to the performance and reliability of commercial trucks. Ensuring that fuel is delivered efficiently and consistently to the engine is paramount for optimal operation. Cummins, a renowned name in the diesel engine industry, has built a reputation for delivering high-quality, durable components. One such essential component is the Cummins Injector Fuel Supply Tube (Part #3968937), which plays a pivotal role in the engine’s fuel injection system.

Basic Concepts Related to the Injector Fuel Supply Tube

An injector fuel supply tube is a vital component in the fuel injection system of commercial trucks. Its primary function is to deliver fuel from the fuel pump to the injectors under precise pressure and flow conditions. The fuel injection system in commercial trucks is designed to atomize fuel into fine particles, ensuring efficient combustion and maximizing engine performance. The injector fuel supply tube interfaces with the fuel pump, fuel filter, and injectors, creating a seamless pathway for fuel delivery 1.

Purpose of the Cummins Injector Fuel Supply Tube (Part #3968937)

The Cummins Injector Fuel Supply Tube (Part #3968937) is integral to the engine’s operation. It maintains the necessary fuel pressure and flow, ensuring that the injectors receive a consistent supply of fuel. This consistency is crucial for achieving optimal combustion efficiency, which directly impacts engine power, fuel economy, and emissions. By ensuring a steady fuel supply, the injector fuel supply tube contributes significantly to the engine’s overall efficiency and performance 2.

How the Injector Fuel Supply Tube Works

The fuel flow process begins at the fuel pump, which pressurizes the fuel and sends it through the fuel lines. The injector fuel supply tube then carries this pressurized fuel to the injectors. The tube’s design ensures that fuel is delivered consistently, without leaks or interruptions. This consistent delivery is vital for maintaining combustion efficiency and engine power. Any disruption in the fuel supply can lead to engine misfires, reduced power, and increased emissions 3.

Troubleshooting Common Issues

Common problems associated with the injector fuel supply tube include fuel leaks, engine misfires, and inconsistent fuel delivery. Symptoms of a faulty tube may include rough idling, decreased engine performance, and visible fuel leaks. To troubleshoot these issues, start by inspecting the tube for cracks, leaks, or blockages. If any damage is found, the tube should be replaced with a high-quality part to ensure reliable performance. Regular maintenance and inspections can help prevent these issues.

Maintenance Tips

Maintaining the injector fuel supply tube is essential for ensuring the longevity and performance of the fuel system. Best practices include regular inspections for signs of wear or damage, cleaning the tube to remove any debris or contaminants, and using high-quality replacement parts when necessary. Proper maintenance not only enhances the tube’s performance but also contributes to the overall efficiency of the engine.

Cummins: A Leader in Diesel Engine Technology

Cummins has a rich history of innovation and excellence in the diesel engine industry. The company’s commitment to quality and reliability is evident in every component they produce, including the injector fuel supply tube. Cummins’ parts are engineered for durability and performance, ensuring that commercial trucks operate efficiently and reliably. Their dedication to continuous improvement and customer satisfaction sets them apart in the industry.

Expert Insights and Best Practices

Industry experts emphasize the significance of the injector fuel supply tube in the fuel injection system. Best practices for engineers and mechanics include thorough inspections, proper installation techniques, and the use of genuine Cummins parts. Fleet operators are advised to implement regular maintenance schedules and use high-quality components to ensure the longevity of their fuel systems.

Cummins Injector Fuel Supply Tube (Part 3968937) Compatibility

The Cummins Injector Fuel Supply Tube, identified by the part number 3968937, is a critical component in the fuel delivery system of various Cummins engines. This part is designed to ensure the efficient and reliable transfer of fuel from the fuel supply system to the injectors, facilitating optimal engine performance.

Engine Compatibility

- 4B3.9

- 5.9L Cummins

- 6.7L Cummins

The injector fuel supply tube is engineered to fit seamlessly with these engines, ensuring a secure and leak-free connection. This compatibility is crucial for maintaining the integrity of the fuel system and preventing any potential fuel leaks that could compromise engine performance or safety.

Installation and Functionality

When installed, the injector fuel supply tube connects the fuel rail to the injectors, ensuring that fuel is delivered at the correct pressure and flow rate. This part is designed to withstand the high pressures and temperatures inherent in diesel engines, providing durability and reliability over the long term.

Importance of Proper Installation

Proper installation of the injector fuel supply tube is essential to ensure that the engine operates efficiently. Any misalignment or damage to this component can lead to fuel delivery issues, potentially causing engine misfires, reduced power output, or even engine failure. Therefore, it is important to use the correct part and follow the manufacturer’s guidelines for installation.

Role of Part 3968937 Injector Fuel Supply Tube in Engine Systems

The Injector Fuel Supply Tube, identified by part number 3968937, is an integral component in the fuel delivery system of an engine. Its primary function is to transport fuel from the fuel rail to the individual fuel injectors. This ensures a consistent and regulated flow of fuel, which is essential for the precise operation of the injectors.

Integration with Injector Plumbing

The Injector Fuel Supply Tube is a key element in the injector plumbing system. It connects the fuel rail to each injector, providing a dedicated pathway for fuel. This direct connection minimizes the risk of fuel leaks and ensures that each injector receives the exact amount of fuel needed for optimal combustion. The tube’s design allows for efficient fuel distribution, enhancing the overall performance and reliability of the engine.

Interaction with Fuel Rail and Injectors

In conjunction with the fuel rail, the Injector Fuel Supply Tube maintains a stable fuel pressure across all injectors. The fuel rail acts as a reservoir, supplying fuel to the tubes, which then deliver it to the injectors. This system ensures that each cylinder receives an equal amount of fuel, promoting balanced combustion and efficient engine operation.

Role in Overall Fuel System

The Injector Fuel Supply Tube is part of a larger fuel system that includes the fuel pump, fuel filter, and fuel injectors. The fuel pump pressurizes the fuel, which is then filtered to remove impurities before reaching the fuel rail. The Injector Fuel Supply Tube ensures that this pressurized, clean fuel is delivered to the injectors in a controlled manner. This precise fuel delivery is vital for maintaining engine efficiency, reducing emissions, and enhancing overall performance.

Ensuring System Integrity

Proper installation and maintenance of the Injector Fuel Supply Tube are essential for the integrity of the fuel system. Regular inspections for wear, leaks, or blockages can prevent potential issues that could affect engine performance. Ensuring that the tube is securely connected to both the fuel rail and the injectors is also important for maintaining a sealed and efficient fuel delivery system.

Conclusion

The Cummins Injector Fuel Supply Tube (Part #3968937) is a critical component in the fuel injection system of commercial trucks. Its role in maintaining fuel pressure and flow is essential for engine efficiency and performance. Proper maintenance and troubleshooting are key to preventing engine issues and ensuring reliable operation. By understanding the importance of this component and following best practices, mechanics and engineers can contribute to the optimal performance of commercial truck engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.