5271591

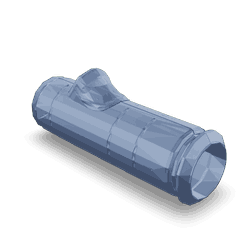

Decomposition Reactor

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 5271591 Decomposition Reactor is a component designed to enhance the emissions control system in commercial trucks. It facilitates the breakdown of urea, a key ingredient in Diesel Exhaust Fluid (DEF), into ammonia and carbon dioxide. This process is integral to the Selective Catalytic Reduction (SCR) system, which reduces nitrogen oxides (NOx) emissions, contributing to cleaner air and compliance with environmental regulations 1.

Basic Concepts of Decomposition Reactors

A decomposition reactor accelerates the breakdown of urea into ammonia and carbon dioxide. Within a truck’s emissions control system, this reactor ensures that the urea in the DEF is effectively decomposed before it enters the SCR catalyst. The basic principle behind its operation involves thermal decomposition, where heat is applied to facilitate the chemical reaction that breaks down urea 2.

Purpose of the 5271591 Decomposition Reactor

This Cummins part plays a specific role in the truck’s emissions control system by ensuring that the urea in the DEF is properly decomposed. This decomposition is necessary for the SCR system to function effectively. The reactor interacts with the DEF system by receiving the urea solution and with the SCR system by providing the decomposed ammonia, which is used to convert NOx into harmless nitrogen and water 3.

Key Features

The 5271591 Decomposition Reactor is characterized by its robust design and the materials used in its construction. It is built to withstand the high temperatures and pressures within the exhaust system. The reactor’s design includes a housing that protects the internal components and ensures efficient decomposition. Additionally, the use of high-quality materials enhances its durability and performance under demanding conditions.

Benefits

The benefits of this part include improved emissions control, which leads to reduced NOx emissions and better air quality. Enhanced engine performance is another advantage, as the efficient decomposition of urea ensures that the SCR system operates optimally. Compliance with environmental regulations is also facilitated by the reactor, helping truck operators meet stringent emissions standards.

Installation and Integration

Proper installation of this part involves several steps to ensure it is correctly integrated into the truck’s emissions control system. Prerequisites include verifying that the exhaust system is clean and free of obstructions. The reactor should be installed in a location that allows for adequate heat management and ensures that the decomposed urea is effectively delivered to the SCR catalyst.

Operational Efficiency

This part contributes to the overall operational efficiency of the truck by ensuring that the SCR system functions correctly. This leads to improved fuel economy, as the engine can operate more efficiently when emissions are properly controlled. Maintenance requirements are minimal, but regular checks are recommended to ensure the reactor continues to perform optimally.

Troubleshooting and Maintenance

Common issues with this part may include blockages or inefficiencies in the decomposition process. Troubleshooting involves checking for obstructions and ensuring that the reactor is receiving the correct temperature and pressure conditions. Maintenance practices include regular inspections and cleaning to prevent buildup and ensure longevity.

Regulatory Compliance

This part assists trucks in meeting emissions regulations and standards by ensuring that NOx emissions are effectively reduced. It contributes to compliance with environmental regulations, providing truck operators with the necessary certifications and documentation to operate within legal limits.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history of innovation and a mission to make a difference, Cummins plays a significant role in the development and manufacturing of advanced emissions control technologies. The company’s commitment to sustainability and environmental responsibility is reflected in its product offerings, including the 5271591 Decomposition Reactor.

Cummins Decomposition Reactor Part 5271591 Compatibility

The Cummins Decomposition Reactor part number 5271591 is designed to enhance the performance and efficiency of specific Cummins engine models. This part is engineered to fit seamlessly with the following engine series:

- ISB6.7 CM2350 B101

- ISX12 CM2350 X102

- ISX15 CM2350 X101

- X15 CM2350 X116B

These engines, while distinct in their specifications and applications, share common design elements that allow the Decomposition Reactor to integrate effectively. The part’s compatibility with these engines underscores its versatility and the broad applicability of Cummins’ engineering solutions.

The Decomposition Reactor is integral to the operational integrity of these engines, providing essential functions that contribute to their overall performance. Its design ensures that it can be installed with ease, maintaining the reliability and efficiency expected from Cummins products.

Understanding the Integration of Part 5271591 Decomposition Reactor in Engine Systems

The decomposition reactor (part 5271591) is a specialized component within the aftertreatment system of modern engines. Its primary function is to facilitate the breakdown of harmful pollutants in the exhaust stream before they are expelled into the atmosphere.

When integrated into the engine system, the decomposition reactor works in concert with other components to ensure optimal performance and emissions control. Here’s how it fits within the broader context of the engine’s aftertreatment system:

-

Exhaust Plumbing: The decomposition reactor is positioned within the exhaust plumbing, where it receives the exhaust gases directly from the engine. This placement ensures that the reactor can immediately begin the process of breaking down pollutants as the exhaust flows through it.

-

Aftertreatment Devices: Alongside other aftertreatment devices such as diesel particulate filters (DPF) and selective catalytic reduction (SCR) systems, the decomposition reactor plays a role in a multi-stage purification process. While the DPF captures solid particles, and the SCR system converts nitrogen oxides into nitrogen and water, the decomposition reactor targets specific compounds that require thermal or catalytic decomposition.

-

Aftertreatment System Coordination: The reactor’s operation is often coordinated with the engine control unit (ECU) to optimize performance. Sensors monitor the exhaust stream and provide feedback to the ECU, which adjusts the reactor’s parameters to maintain efficiency under varying load conditions.

In summary, the decomposition reactor (part 5271591) is an integral component that enhances the overall effectiveness of the aftertreatment system. Its role in breaking down pollutants complements the functions of other aftertreatment devices, contributing to a cleaner and more efficient engine operation.

Conclusion

The Cummins 5271591 Decomposition Reactor is a vital component in the emissions control system of commercial trucks. By ensuring the efficient decomposition of urea in DEF, it supports the SCR system in reducing NOx emissions, thereby contributing to cleaner air and regulatory compliance. Its robust design, compatibility with specific Cummins engine models, and integration within the aftertreatment system highlight its importance in modern engine technology.

-

Limpert, Rudolf. Brake Design and Safety, Third Edition. SAE International, 2011.

↩ -

Smil, Vaclav. The History and Impact of Diesel Engines and Gas Turbines. The MIT Press, 2010.

↩ -

Duffy, Owen C, and Gus Wright. Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning, 2016.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.