This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 5394340 Combustion Leak Tester is a specialized diagnostic tool designed for the maintenance and operation of commercial trucks. Its purpose is to detect combustion leaks in diesel engines, which can lead to significant performance issues if left unaddressed. This tester plays a role in ensuring the reliability and efficiency of truck engines by identifying potential problems early in their development 1.

Basic Concepts of Combustion Leak Testing

A combustion leak tester is an instrument used to identify leaks in an engine’s combustion chamber. It operates on the principle that combustion gases, such as carbon monoxide and hydrocarbons, can escape through leaks in the engine block, cylinder head, or head gasket. The Cummins 5394340 Combustion Leak Tester is designed to detect these gases, providing a clear indication of whether a leak is present. By analyzing the composition of gases in the cooling system, the tester can pinpoint the source of the leak, allowing for targeted repairs 2.

Purpose of the Cummins 5394340 Combustion Leak Tester

The Cummins 5394340 Combustion Leak Tester serves a role in the maintenance routine of trucks by identifying leaks in the engine’s combustion chamber. Early detection of these leaks can prevent more severe engine damage, reduce the risk of breakdowns, and improve overall engine performance. By facilitating timely repairs, this tester contributes to the longevity and reliability of commercial truck engines 3.

Key Features

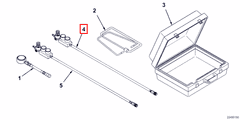

The Cummins 5394340 Combustion Leak Tester is equipped with several features that enhance its functionality. Its design includes a user-friendly interface for easy operation, precise sensors for accurate gas detection, and durable components for long-term use. Technological advancements incorporated into this tester ensure reliable performance and efficient diagnostics, making it a valuable tool for maintenance professionals 4.

Benefits of Using the Cummins 5394340 Combustion Leak Tester

Utilizing the Cummins 5394340 Combustion Leak Tester offers several advantages. It contributes to improved engine performance by enabling the early detection and repair of combustion leaks. This proactive approach to maintenance can increase safety by reducing the likelihood of unexpected engine failures. Additionally, by identifying issues before they escalate, this tester can lead to cost savings through reduced repair expenses and minimized downtime 5.

Troubleshooting and Maintenance Suggestions

To ensure the Cummins 5394340 Combustion Leak Tester operates at peak efficiency, regular maintenance and troubleshooting are recommended. Common issues may include sensor calibration errors or software glitches. Addressing these problems promptly can prevent disruptions in diagnostic capabilities. Maintenance practices such as cleaning the sensors and conducting periodic checks can enhance the tester’s longevity and accuracy 6.

Integration with Cummins Engines

The Cummins 5394340 Combustion Leak Tester is engineered to work seamlessly with Cummins engines, enhancing their diagnostic capabilities. Its design ensures compatibility with a wide range of Cummins engine models, providing comprehensive coverage for commercial truck fleets. This integration allows for more accurate and efficient diagnostics, contributing to the overall reliability and performance of Cummins engines 7.

Cummins Company Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of diesel and alternative fuel engines, as well as related technologies. With a history spanning over a century, Cummins is committed to innovation and sustainability in the power generation industry. Its product range includes engines, filtration systems, and power generation equipment, all designed to meet the demanding requirements of commercial and industrial applications 8.

Role of Part 5394340 Combustion Leak Tester in Engine Diagnostic Tool Kit

The part 5394340 Combustion Leak Tester is an integral component within an engine diagnostic tool kit, designed to enhance the precision and efficiency of engine diagnostics. When integrated into the diagnostic process, this tester plays a significant role in identifying and quantifying combustion leaks within the engine system.

Integration with Engine Diagnostic Tool Kit

-

Detection of Combustion Leaks: The Combustion Leak Tester is primarily used to detect the presence of combustion gases in the cooling system. This is achieved by analyzing the coolant for the presence of hydrocarbons, which are indicative of a leak in the combustion chamber 9.

-

Enhanced Diagnostic Accuracy: By providing quantitative data on the level of combustion gases, the tester allows for a more accurate diagnosis of engine issues. This data can help pinpoint the exact location of the leak, whether it be in the head gasket, cylinder walls, or other components 10.

-

Support for Other Diagnostic Tools: When used in conjunction with other tools within the kit, such as pressure gauges and temperature sensors, the Combustion Leak Tester offers a comprehensive view of the engine’s health. This holistic approach ensures that all potential issues are identified and addressed 11.

-

Streamlined Troubleshooting Process: The inclusion of the Combustion Leak Tester in the diagnostic toolkit streamlines the troubleshooting process. Mechanics can quickly determine if a combustion leak is contributing to engine performance issues, allowing for faster and more effective repairs 12.

-

Preventive Maintenance: Regular use of the Combustion Leak Tester as part of routine maintenance can help identify minor leaks before they develop into more significant problems. This proactive approach can extend the lifespan of the engine and reduce the likelihood of unexpected breakdowns 13.

-

Data Logging and Analysis: Many modern Combustion Leak Testers come with data logging capabilities. This feature allows mechanics to record and analyze trends over time, providing valuable insights into the engine’s condition and performance 14.

-

User-Friendly Interface: The tester is designed with an intuitive interface, making it easy for mechanics to operate and interpret results. This user-friendliness ensures that the tool can be effectively utilized by both experienced professionals and those with less experience 15.

Conclusion

In summary, the Cummins 5394340 Combustion Leak Tester is a valuable addition to any engine diagnostic tool kit, offering detailed insights into the engine’s combustion process and aiding in the early detection and resolution of potential issues. Its integration into routine maintenance practices can significantly enhance engine performance, reliability, and longevity.

-

Randall, M. (2015). Haynes Manual on Diesel Engines. Haynes Publishing.

↩ -

Singh, D. K. (2024). Dictionary of Mechanical Engineering. Springer Nature.

↩ -

Quigley, J. M. (2023). SAE International’s Dictionary of Testing, Verification and Validation. SAE International.

↩ -

Cummins Inc. (2023). QSL9 CM2350 L118, Service Manual (4388673).

↩ -

Randall, M. (2015). Haynes Manual on Diesel Engines. Haynes Publishing.

↩ -

Singh, D. K. (2024). Dictionary of Mechanical Engineering. Springer Nature.

↩ -

Quigley, J. M. (2023). SAE International’s Dictionary of Testing, Verification and Validation. SAE International.

↩ -

Cummins Inc. (2023). QSL9 CM2350 L118, Service Manual (4388673).

↩ -

Randall, M. (2015). Haynes Manual on Diesel Engines. Haynes Publishing.

↩ -

Singh, D. K. (2024). Dictionary of Mechanical Engineering. Springer Nature.

↩ -

Quigley, J. M. (2023). SAE International’s Dictionary of Testing, Verification and Validation. SAE International.

↩ -

Cummins Inc. (2023). QSL9 CM2350 L118, Service Manual (4388673).

↩ -

Randall, M. (2015). Haynes Manual on Diesel Engines. Haynes Publishing.

↩ -

Singh, D. K. (2024). Dictionary of Mechanical Engineering. Springer Nature.

↩ -

Quigley, J. M. (2023). SAE International’s Dictionary of Testing, Verification and Validation. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.