4101401

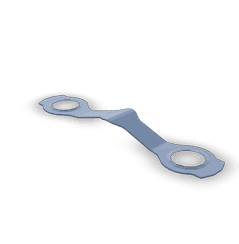

Lockplate

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4101401 Lock Plate is a component designed for use in commercial trucks, specifically within the engine assembly. A lock plate, in general, serves to secure fasteners in place, preventing them from loosening due to vibrations or other dynamic forces encountered during operation. This particular lock plate is engineered to meet the rigorous demands of heavy-duty applications, ensuring components remain firmly in place under various operating conditions 1.

Purpose and Function

The Cummins 4101401 Lock Plate is utilized in heavy-duty truck engines to secure fasteners, such as bolts and screws, in critical assemblies. Its role is to maintain the integrity of the assembly by preventing fasteners from loosening, which could lead to component misalignment, increased wear, or even failure. By securing fasteners, the lock plate contributes to the overall stability and reliability of the engine, ensuring that all components function as intended throughout the vehicle’s operation 2.

Key Features

The Cummins 4101401 Lock Plate is characterized by its robust material composition, typically made from high-strength steel or a similar durable alloy. This material choice ensures the lock plate can withstand the high stresses and vibrations common in heavy-duty truck engines. Its design includes precise dimensions and a secure locking mechanism that effectively holds fasteners in place. Additionally, the lock plate may feature a unique shape or pattern that enhances its grip on the fastener, further contributing to its performance and durability 3.

Benefits

Utilizing the Cummins 4101401 Lock Plate offers several advantages. It enhances safety by ensuring that critical engine components remain securely fastened, reducing the risk of unexpected failures. The lock plate’s durable construction contributes to the engine’s longevity, as it helps prevent wear and damage caused by loose fasteners. Furthermore, its reliable performance under demanding conditions typical of heavy-duty truck operations ensures that the engine maintains optimal efficiency and functionality.

Installation and Usage

Proper installation of the Cummins 4101401 Lock Plate is crucial for its effectiveness. It should be installed according to the manufacturer’s guidelines, ensuring that it is correctly aligned with the fastener and the component it secures. Care should be taken to avoid over-tightening, which could damage the lock plate or the fastener. Regular inspections during maintenance checks can help ensure that the lock plate remains in good condition and continues to perform its intended function.

Troubleshooting and Maintenance

Common issues with lock plates may include deformation or damage due to improper installation or excessive vibration. If a lock plate appears damaged or ineffective, it should be replaced to maintain the security of the fastener. Regular maintenance, including inspection for signs of wear or damage, can help identify potential issues before they lead to more significant problems. Keeping the lock plate and surrounding components clean and free of debris can also contribute to its longevity and effectiveness.

Compatibility and Applications

The Cummins 4101401 Lock Plate is designed for use within various Cummins engine models, specifically tailored to meet the demands of heavy-duty truck applications. Its compatibility extends to a range of engine configurations, ensuring that it can be effectively utilized across different vehicle models and operating conditions within the heavy-duty trucking industry.

Manufacturer Overview - Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the heavy-duty truck and engine manufacturing industry. The company’s extensive product range includes engines for on-highway and off-highway applications, filtration systems, and power generation equipment, serving a wide array of industries and applications.

Lock Plate 4101401 Compatibility with Cummins Engines

The Lock Plate 4101401, manufactured by Cummins, is a critical component designed to fit seamlessly with several of their engine models. This part is essential for maintaining the structural integrity and operational efficiency of the engines it is compatible with.

QSK45 CM500 and QSK60 CM500

The Lock Plate 4101401 is specifically engineered to fit the QSK45 CM500 and QSK60 CM500 engines. These engines are part of Cummins’ QSK series, known for their robust design and high performance. The lock plate ensures that various engine components remain securely fastened, preventing any unwanted movement that could lead to mechanical failures or inefficiencies.

QSK60 CM850 MCRS

In addition to the QSK45 CM500 and QSK60 CM500, the Lock Plate 4101401 is also compatible with the QSK60 CM850 MCRS engine. This particular engine model is equipped with the Marine Command RS (MCRS) system, which enhances control and monitoring capabilities. The lock plate’s role in this engine is equally vital, as it supports the additional components and systems integrated into the MCRS setup.

Grouping of Compatible Engines

The Lock Plate 4101401 is designed to fit within the QSK series of engines, specifically those with CM500 and CM850 configurations. This grouping ensures that the lock plate meets the specific requirements and design standards of these engine models, providing a reliable and secure fit.

Role of Part 4101401 Lock Plate in Engine Systems

The 4101401 Lock Plate is an essential component that ensures the secure fitting and alignment of various engine parts. It plays a significant role in maintaining the integrity and performance of the engine system by providing a stable and reliable connection between components.

Integration with Cylinder Head Gasket Kit and Set

When installing a Cylinder Head Gasket Kit or Cylinder Head Gasket Set, the 4101401 Lock Plate is used to secure the cylinder head to the engine block. This ensures that the gasket is properly compressed and sealed, preventing any leaks between the combustion chamber and the coolant passages. The lock plate helps maintain the correct torque specifications, which is vital for the gasket’s effectiveness.

Application in Exhaust Manifold and Manifold

In the Exhaust Manifold and Manifold systems, the 4101401 Lock Plate is employed to secure the manifold to the cylinder head. This connection is critical for directing exhaust gases away from the engine efficiently. The lock plate ensures that the manifold remains firmly attached, even under the high temperatures and pressures of the exhaust system.

Use with Head Quadrant Gasket Kit

The Head Quadrant Gasket Kit requires precise alignment and secure fitting to function correctly. The 4101401 Lock Plate aids in this by providing a robust connection between the head quadrant and the engine block. This ensures that the gasket maintains its seal, preventing any unwanted leaks that could affect engine performance.

Role in Oversize Gasket Kit

An Oversize Gasket Kit is often used to address issues with warped or damaged surfaces. The 4101401 Lock Plate ensures that these thicker gaskets are properly compressed and sealed. This is particularly important in high-performance engines where maintaining a perfect seal is essential for optimal operation.

Quadrant Cylinder Hardware Gasket Set

In the Quadrant Cylinder Hardware Gasket Set, the 4101401 Lock Plate is utilized to secure the quadrant cylinder hardware in place. This ensures that the gasket set functions as intended, providing a reliable seal and preventing any potential leaks that could compromise engine efficiency.

Single Head Gasket Kit

For the Single Head Gasket Kit, the 4101401 Lock Plate is integral in securing the single head gasket between the cylinder head and the engine block. This ensures that the gasket is evenly compressed, creating a reliable seal that is essential for the engine’s combustion process.

Quad Ovrsz Cyl Hd Gsk

In applications involving the Quad Ovrsz Cyl Hd Gsk, the 4101401 Lock Plate ensures that the oversize cylinder head gasket is properly installed and sealed. This is particularly important in engines that have undergone modifications or repairs, where maintaining a perfect seal is crucial for performance and reliability.

Conclusion

The Cummins 4101401 Lock Plate is a vital component in the maintenance and operation of heavy-duty truck engines. Its robust design, precise engineering, and compatibility with various Cummins engine models make it an essential part for ensuring the secure fitting and alignment of engine components. By preventing fastener loosening and maintaining the integrity of critical assemblies, this part contributes significantly to the safety, reliability, and efficiency of the engine system.

-

Bonneau, D., Fatu, A., & Souchet, D. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

↩ -

Harrison, M. (2004). Controlling Noise and Vibration in Road Vehicles. SAE International.

↩ -

Stiesch, G. (2003). Modeling Engine Spray and Combustion Processes. Springer Verlag.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.