This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

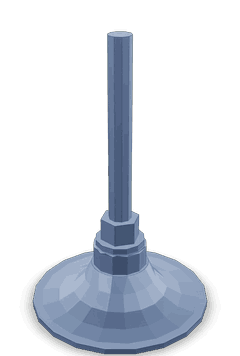

The 3824538 Abrasive Disc Arbor, manufactured by Cummins, is a critical component in the maintenance and operation of commercial trucks. This part ensures reliable grinding and polishing tasks, which are essential for truck upkeep.

Basic Concepts of Abrasive Disc Arbors

An abrasive disc arbor is a tool designed to connect abrasive discs to machinery, facilitating efficient grinding, polishing, and cutting operations. It provides a secure and stable connection between the abrasive disc and the machine, ensuring optimal performance without slippage or misalignment 1.

Purpose of the 3824538 Abrasive Disc Arbor in Truck Operation

This Cummins part is integral to the maintenance and repair processes of commercial trucks. It enables the attachment of abrasive discs to grinding machines, allowing for the precise removal of rust, paint, and other materials from truck components. This ensures that truck parts are maintained in optimal condition, contributing to the vehicle’s efficiency and safety 2.

Key Features of the 3824538 Abrasive Disc Arbor

The 3824538 is characterized by its robust design and construction. Made from high-quality materials, it ensures durability and reliability under demanding conditions. The arbor is engineered to precise dimensional specifications, ensuring a secure fit with both the grinding machine and the abrasive disc. Unique design elements enhance the stability and performance of the abrasive disc during operation 3.

Benefits of Using the 3824538 Abrasive Disc Arbor

Utilizing this part offers several advantages. It improves efficiency in grinding operations by providing a stable and secure connection between the abrasive disc and the grinding machine. Its durability ensures long-term use, reducing the need for frequent replacements. Additionally, its compatibility with various abrasive discs allows for versatile application in different maintenance tasks.

Installation Process

Installing the 3824538 involves several steps to ensure proper setup. First, the grinding machine should be turned off and unplugged to ensure safety. Next, the arbor is attached to the machine’s spindle, followed by the secure fitting of the abrasive disc onto the arbor. It is important to use the appropriate tools and follow the manufacturer’s guidelines to ensure a correct and safe installation.

Maintenance and Care

Regular maintenance and care of the 3824538 are vital for ensuring its longevity and optimal performance. This includes cleaning the arbor after each use to remove any debris or residue, inspecting it for signs of wear or damage, and lubricating moving parts as necessary. Proper storage in a dry, clean environment will also help maintain the arbor’s condition.

Troubleshooting Common Issues

Common issues with the 3824538 may include difficulties in securing the abrasive disc, vibrations during operation, or premature wear. These problems can often be addressed by ensuring the arbor is correctly installed, checking for any damage or misalignment, and replacing worn components as needed. Regular maintenance can help prevent many of these issues from arising.

Safety Considerations

When using the 3824538, it is important to observe several safety guidelines. This includes wearing appropriate personal protective equipment, such as gloves and eye protection, to safeguard against flying debris. The grinding machine should be securely anchored, and the work area should be clear of any obstructions. Additionally, users should be trained in the safe operation of the machine and the handling of abrasive discs.

Role of the 3824538 Abrasive Disc Arbor in Turbocharger Repair Kit

When addressing the maintenance and repair of turbochargers, the integration of the 3824538 is instrumental. This component facilitates the precise fitting and securement of abrasive discs, which are essential for the honing and polishing processes during turbocharger refurbishment.

Turbocharger Compressor Wheel

The abrasive disc arbor is utilized to mount abrasive discs that are employed to restore the compressor wheel’s surface finish. This ensures optimal airflow and efficiency, directly impacting the turbocharger’s performance.

Turbine Wheel

Similarly, when working on the turbine wheel, the arbor holds abrasive discs that help in removing contaminants and restoring the wheel’s aerodynamic profile. This is vital for maintaining the turbine’s ability to convert exhaust gases into rotational energy effectively.

Bearing Housing

In the context of bearing housing repair, the arbor assists in the precise application of abrasive discs to clean and smooth internal surfaces. This is important for ensuring that the bearings operate within specified tolerances, reducing friction and wear.

Center Housing

The center housing, which connects the compressor and turbine, also benefits from the use of the abrasive disc arbor. It allows for the meticulous cleaning and polishing of the housing’s internal passages, which is essential for maintaining the integrity of the turbocharger’s seals and overall performance.

Shaft

During shaft refurbishment, the arbor is employed to hold abrasive discs that remove imperfections and restore the shaft’s surface to its original specifications. This is key for ensuring smooth rotation and minimizing vibrations.

Seals

Seal maintenance within the turbocharger is another area where the abrasive disc arbor plays a role. It helps in the careful polishing of seal surfaces, which is necessary for achieving the proper fit and function, thereby preventing leaks and ensuring efficient operation.

Conclusion

The 3824538 Abrasive Disc Arbor is a versatile component that enhances the precision and effectiveness of various maintenance and repair procedures within turbocharger systems. Its role in securing abrasive discs ensures that each turbocharger component is restored to optimal condition, contributing to the overall reliability and performance of the engine system.

References

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.