This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

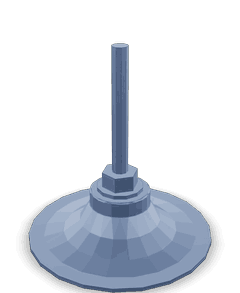

The 3824539 Abrasive Disc Arbor, manufactured by Cummins, is a specialized component designed for use in commercial trucks. This arbor is integral to various maintenance and repair processes, particularly in tasks involving grinding, polishing, and surface preparation. Cummins, a well-established name in the commercial truck and engine industry, ensures that this component meets high standards of quality and performance 1.

Basic Concepts of Abrasive Disc Arbors

An abrasive disc arbor is a tool component that connects grinding or polishing discs to grinding machines. It facilitates the rotation and application of abrasive materials to surfaces, enabling precise and efficient material removal or surface finishing. In industrial and automotive settings, abrasive disc arbors are used for a variety of applications, including metalworking, woodworking, and the maintenance of vehicle components 2.

Role of the Abrasive Disc Arbor in Truck Operations

The 3824539 plays a significant role in the maintenance and repair of commercial trucks. It is used in conjunction with grinding and polishing equipment to perform tasks such as removing rust, smoothing welds, and preparing surfaces for painting or coating. By ensuring that truck components are in optimal condition, this arbor contributes to the overall efficiency and safety of truck operations. Its application in these tasks helps maintain the high standards required for commercial vehicle maintenance 3.

Key Features of the 3824539

The 3824539 is designed with several features that enhance its performance and durability. It is constructed from high-quality materials to withstand the rigors of industrial use. The arbor is engineered to fit standard abrasive discs, ensuring compatibility with a wide range of grinding and polishing applications. Its design includes precise dimensions and a robust construction that allows for efficient and reliable operation in various maintenance tasks 4.

Benefits of Using the 3824539

Using the 3824539 offers several advantages. It provides improved efficiency in grinding tasks, allowing for quicker and more precise material removal. The arbor’s compatibility with various abrasive discs ensures versatility in different applications. Additionally, it contributes to maintaining high standards of truck component finishes, which is vital for the longevity and performance of commercial trucks. The robust construction and precise engineering of the arbor ensure durability and reliability in demanding industrial environments 5.

Troubleshooting and Maintenance

Common issues that may arise with the use of the 3824539 include wear and tear from frequent use and potential misalignment with abrasive discs. Regular maintenance practices, such as inspecting for damage, ensuring proper alignment, and replacing worn components, are recommended to ensure longevity and optimal performance. Safe handling and operation involve following manufacturer guidelines and using appropriate personal protective equipment to prevent injuries and ensure efficient use of the arbor .

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck and engine industry. The company is known for its commitment to quality, innovation, and customer satisfaction. Cummins offers a wide range of products and services designed to meet the needs of various industries, ensuring that their components, including the 3824539, deliver reliable performance and durability .

Conclusion

The 3824539 Abrasive Disc Arbor is a critical component in the maintenance and repair of commercial trucks. Its robust construction, precise engineering, and compatibility with various abrasive discs make it a versatile and reliable tool for grinding and polishing tasks. Regular maintenance and proper use ensure its longevity and optimal performance, contributing to the efficiency and safety of truck operations.

-

Viskup, Richard. Diesel and Gasoline Engines. IntechOpen, 2020.

↩ -

Watson, Ben. Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning, 2011.

↩ -

Smil, Vaclav. The History and Impact of Diesel Engines and Gas Turbines. The MIT Press, 2010.

↩ -

Hilgers, Michael. Electrical Systems and Mechatronics, Second Edition. Springer Vieweg, 2023.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4388704, QSF3.8 CM2350 F119.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.