This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3012941 Oil Gauge Tube is a critical component designed to facilitate the monitoring of oil levels within the engine system of heavy-duty trucks. Its role is significant in ensuring the engine operates efficiently and reliably by providing accurate oil level readings. This component is integral to the maintenance and performance monitoring of the vehicle’s engine.

Basic Concepts of Oil Gauge Tubes

An oil gauge tube is a component that allows for the measurement and monitoring of oil levels within an engine. It functions by connecting to the engine’s oil system and providing a pathway for oil to reach the gauge, which displays the current oil level. This monitoring is vital for maintaining engine health, as it ensures that the engine is adequately lubricated, which is necessary for reducing friction and wear on moving parts 1.

Purpose of the Cummins 3012941 Oil Gauge Tube

The Cummins 3012941 Oil Gauge Tube serves to maintain optimal engine performance by accurately measuring oil levels. It plays a role in the engine’s lubrication system by ensuring that the oil level is within the required range. This accurate measurement aids in preventing engine damage due to insufficient lubrication and helps in identifying potential leaks or consumption issues early 2.

Key Features

The Cummins 3012941 Oil Gauge Tube is characterized by its durable construction, which is designed to withstand the harsh conditions within an engine environment. It offers precise measurement capabilities, ensuring that the oil level readings are accurate. Additionally, it is compatible with Cummins engines, making it a suitable choice for maintaining the performance and reliability of these engines.

Benefits

Utilizing the Cummins 3012941 Oil Gauge Tube offers several advantages. It contributes to improved engine reliability by ensuring that oil levels are monitored accurately. This component enhances performance monitoring capabilities, allowing for timely maintenance and adjustments. Furthermore, its design facilitates ease of installation, reducing downtime during maintenance procedures.

Installation Process

Installing the Cummins 3012941 Oil Gauge Tube involves several steps to ensure accurate placement and function. The process requires specific tools and adherence to safety precautions. It begins with the removal of the old gauge tube, if present, followed by the installation of the new tube into the designated port. Careful attention to alignment and securing the tube is necessary to prevent leaks and ensure accurate readings.

Maintenance Tips

To ensure the longevity and accurate performance of the Cummins 3012941 Oil Gauge Tube, regular maintenance is recommended. This includes periodic inspection for signs of wear or damage and cleaning the tube to remove any debris that may affect its operation. Proper maintenance helps in sustaining the component’s functionality and contributes to the overall efficiency of the engine.

Troubleshooting Common Issues

Common issues associated with oil gauge tubes, such as inaccurate readings or leaks, can often be addressed through systematic troubleshooting. Inaccurate readings may be due to blockages within the tube or gauge, requiring cleaning or replacement. Leaks can be identified through visual inspection and may necessitate re-sealing or replacing the tube. Addressing these issues promptly helps in maintaining engine performance and reliability.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history of innovation and commitment to quality, Cummins serves customers in approximately 190 countries and territories, providing products and services that drive economic growth and improve the quality of life. The company’s extensive product range and focus on technological advancement underscore its position as a leader in the diesel engine and power generation markets 3.

Compatibility of Cummins Oil Gauge Tube Part 3012941

The Cummins Oil Gauge Tube part number 3012941 is designed to fit seamlessly into various Cummins engine models, ensuring accurate monitoring and maintenance of the engine’s oil conditions. This part is integral to the engine’s design, ensuring that the oil level and pressure are consistently monitored.

V903 Engine Series

The V903 engine series, known for its robust performance and reliability, incorporates the Cummins Oil Gauge Tube part 3012941. This part is integral to the engine’s design, ensuring that the oil level and pressure are consistently monitored. The V903 engines, often used in heavy-duty applications, benefit from the precision and reliability of this oil gauge tube, contributing to the overall efficiency and longevity of the engine.

Grouping of Compatible Engines

The Cummins Oil Gauge Tube part 3012941 is compatible with a range of other Cummins engines, including but not limited to:

- QSK Series: This series of engines is widely used in power generation and industrial applications. The oil gauge tube ensures that operators can maintain optimal oil levels and pressure, crucial for the high-performance demands of these engines.

- QSC Series: Known for their versatility, the QSC engines are used in a variety of applications, from marine to construction. The oil gauge tube part 3012941 is designed to fit these engines, providing reliable oil monitoring and contributing to the engine’s overall performance.

- QSJ Series: These engines are often used in military and defense applications, where reliability and performance are paramount. The oil gauge tube is a critical component, ensuring that the engine’s oil conditions are always within safe limits.

By ensuring compatibility with a wide range of Cummins engines, the Oil Gauge Tube part 3012941 plays a vital role in maintaining the health and performance of these engines across various applications.

Role of Part 3012941 Oil Gauge Tube in Engine Systems

The 3012941 Oil Gauge Tube is an integral component within various engine systems, facilitating the accurate measurement and monitoring of oil levels. Its function is essential for maintaining the health and efficiency of the engine.

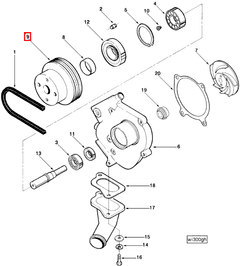

Integration with Engine Components

Connection

The Oil Gauge Tube interfaces directly with the oil level sensor, providing a conduit for the sensor to measure the oil level within the engine. This connection ensures that the sensor receives accurate data, which is then relayed to the oil gauge on the dashboard. The precision of this connection is vital for the reliable operation of the oil level monitoring system.

Water Inlet

While the Oil Gauge Tube primarily deals with oil, its accurate functioning can indirectly affect components like the water inlet. Proper oil levels, as indicated by the gauge, help in maintaining optimal engine temperature. An overfilled or underfilled oil system can lead to inefficient cooling, impacting the water inlet’s performance. Thus, the Oil Gauge Tube plays a supportive role in ensuring that the water inlet operates within the desired parameters by providing accurate oil level readings.

Water Pump

The water pump is responsible for circulating coolant throughout the engine to prevent overheating. The Oil Gauge Tube, by ensuring accurate oil levels, contributes to the overall thermal management of the engine. Proper oil levels help in lubricating moving parts, reducing friction and heat generation. This, in turn, allows the water pump to function more effectively, as the engine operates within a stable temperature range.

Conclusion

In summary, the 3012941 Oil Gauge Tube is a key component in the engine’s oil management system, with its accurate readings supporting the efficient operation of interconnected systems such as the water inlet and water pump. Its role in maintaining optimal engine performance and reliability cannot be overstated.

-

Libby Osgood, Gayla Cameron, and Emma Christensen, Engineering Mechanics: Statics (Creative Commons, 2024).

↩ -

James D. Halderman, Automotive Principles: Diagnosis and Service (Prentice Hall, 2012).

↩ -

Owen C Duffy and Gus Wright, Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems (Jones Bartlett Learning, 2016).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.