This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

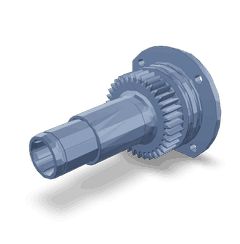

The Accessory Drive Support, part number 5271646, is a component manufactured by Cummins, designed to enhance the operation of commercial trucks. This part is integral to the engine system, providing support for various accessories and contributing to the overall efficiency and performance of the truck. Cummins is known for producing reliable and high-quality parts that meet the demanding requirements of commercial vehicles .

Function and Operation

The Accessory Drive Support operates within the truck’s engine system by providing a stable platform for the attachment of various accessories. These accessories may include components such as alternators, air compressors, and power steering pumps. The support ensures that these accessories are securely mounted and properly aligned, which is vital for their efficient operation. By maintaining the correct positioning and tension of the drive belts, the Accessory Drive Support plays a role in ensuring that power is effectively transmitted from the engine to these accessories .

Purpose of the Accessory Drive Support

The Accessory Drive Support is designed to facilitate the smooth and efficient running of engine accessories. It achieves this by providing a robust and stable mounting point that can withstand the vibrations and stresses inherent in the operation of a commercial truck engine. This support is particularly important in ensuring that accessories operate within their designed parameters, thereby contributing to the overall reliability and performance of the truck .

Key Features

The Accessory Drive Support boasts several key features that enhance its functionality and durability. It is constructed from high-strength materials, ensuring it can endure the rigors of commercial truck use. The design incorporates precise mounting points and alignment features, which are crucial for the proper installation and operation of accessories. Additionally, the support is engineered to minimize vibrations, which can otherwise lead to premature wear and failure of both the support and the accessories it holds .

Benefits

Utilizing the Accessory Drive Support in truck engines offers several advantages. It contributes to improved performance by ensuring that accessories are securely mounted and properly aligned. This results in more efficient operation of the accessories, which can lead to better overall engine performance. The durable construction of the support also enhances the longevity of the accessories, reducing the need for frequent replacements. Furthermore, the reduction in vibrations helps in maintaining the integrity of the engine components, leading to a more reliable and efficient truck operation .

Installation Process

Installing the Accessory Drive Support involves several steps to ensure proper integration into the engine system. First, the engine compartment must be accessed, and any existing support or accessories must be removed. The new support is then positioned according to the manufacturer’s guidelines, ensuring that all mounting points are aligned correctly. Once in place, the support is secured using the appropriate fasteners. Finally, the accessories are reattached to the support, and the drive belts are adjusted to the correct tension. Specific tools may be required for certain steps, such as torque wrenches for tightening fasteners .

Common Issues and Troubleshooting

Common issues with the Accessory Drive Support may include misalignment, loose fasteners, or wear and tear due to prolonged use. Misalignment can lead to inefficient operation of accessories and increased wear on drive belts. Loose fasteners may cause the support to shift, leading to similar issues. Wear and tear can compromise the structural integrity of the support. Troubleshooting these issues involves inspecting the support for signs of damage or misalignment, tightening any loose fasteners, and replacing the support if it shows significant wear .

Maintenance Tips

Regular maintenance of the Accessory Drive Support is important to ensure its continued efficient operation. This includes periodic inspection for signs of wear, corrosion, or damage. Fasteners should be checked for tightness, and any signs of misalignment should be addressed promptly. Additionally, the condition of the drive belts should be monitored, as they rely on the support for proper tension and alignment. Following a scheduled maintenance plan can help in identifying and addressing issues before they lead to more significant problems .

Compatibility and Applications

The Accessory Drive Support is designed to be compatible with a range of Cummins engines commonly found in commercial trucks. Its applications extend to various commercial truck settings, where reliable and efficient engine operation is paramount. The support is engineered to meet the specific requirements of these engines, ensuring that it can handle the stresses and vibrations associated with heavy-duty use .

Cummins: A Brief Overview

Cummins is a renowned manufacturer in the automotive industry, with a strong reputation for producing high-quality engine components and systems. The company has a long history of innovation and excellence, contributing significantly to the advancement of engine technology. Cummins’ commitment to quality and performance is evident in their wide range of products, which are trusted by commercial truck operators worldwide .

Accessory Drive Support Component Usage

The Accessory Drive Support, identified by part number 5271646, is an integral component in the orchestration of various engine systems. It provides a stable mounting platform for accessories that are driven by the engine’s power.

In conjunction with the Flywheel Housing, the Accessory Drive Support ensures that accessories are securely positioned and properly aligned with the engine’s drive mechanisms. This is essential for the efficient transfer of power from the engine to accessories such as the alternator, power steering pump, and air conditioning compressor.

The Housing itself, often part of the engine block or a separate component, works in tandem with the Accessory Drive Support to protect internal engine components and maintain the structural integrity of the engine assembly. It also aids in the management of engine noise and vibration, contributing to a smoother operation.

The Flywheel, a rotating mechanical device, is supported by the Accessory Drive Support in a manner that allows for the smooth engagement of the starter motor and the transmission of rotational energy to the engine’s crankshaft. This interaction is vital for the engine’s starting process and the overall functioning of the drivetrain.

Together, these components form a cohesive system that not only supports the engine’s operation but also enhances the durability and performance of the engine’s accessory systems. The Accessory Drive Support’s role is to facilitate the seamless integration of these components, ensuring that each accessory operates within the precise parameters required for optimal engine performance .

Conclusion

The Accessory Drive Support, part number 5271646, is a critical component for the efficient and reliable operation of commercial truck engines. Its role in supporting and aligning engine accessories ensures that these components operate within their designed parameters, contributing to the overall performance and longevity of the engine. Regular maintenance and proper installation are key to maximizing the benefits of this part.

: Isermann, R. (2017). *Combustion Engine Diagnosis*. Springer Vieweg.

: Genta, G., & Morello, L. (2019). *The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition*. Springer.

: Harrison, M. (2004). *Controlling Noise and Vibration in Road Vehicles*. SAE International.

: Limpert, R. (2011). *Brake Design and Safety, Third Edition*. SAE International.SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.