This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

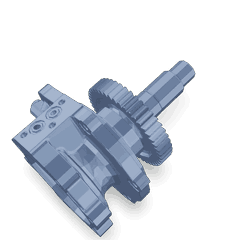

The Accessory Drive Support, part number 5416815, is a component manufactured by Cummins, designed to play a role in the operation of heavy-duty trucks. This part is integral to the accessory drive system, ensuring the efficient transfer of power to various engine accessories. Cummins, a well-established manufacturer in the automotive industry, is known for its commitment to quality and innovation in producing reliable automotive components 1.

Basic Concepts of Accessory Drive Support

An Accessory Drive Support serves as a mounting point and structural component within the engine system. It facilitates the operation of the accessory drive system by providing a stable platform for accessories such as alternators, power steering pumps, and air conditioning compressors. This system is vital for the operation of heavy-duty trucks, as it ensures that all engine accessories receive the necessary power to function correctly 2.

Purpose of the Accessory Drive Support

The Accessory Drive Support is designed to enhance the operation of a truck’s engine by securely mounting and supporting the accessory drive system components. It plays a role in maintaining the alignment and stability of the accessory drive belt, which is crucial for the efficient transfer of power from the engine to the accessories. This support contributes to the overall performance and reliability of the engine 3.

Key Features

This Cummins part is characterized by several key features that enhance its functionality and durability. It is constructed from high-strength materials to withstand the rigors of heavy-duty truck operations. The design incorporates precise engineering to ensure compatibility with Cummins engines and to facilitate easy installation. Additionally, the support is designed to minimize vibrations and noise, contributing to a smoother engine operation 4.

Benefits

Utilizing the Accessory Drive Support offers several benefits, including improved engine efficiency, enhanced durability, and increased reliability. By providing a stable platform for the accessory drive system, this component helps to ensure that engine accessories operate at optimal efficiency. Its robust construction contributes to the longevity of the accessory drive system, reducing the need for frequent replacements. Furthermore, the support’s design helps to maintain the overall performance and reliability of the truck’s engine.

Installation Process

Installing the Accessory Drive Support involves several steps to ensure proper integration with the engine system. Begin by locating the mounting points on the engine block and securing the support in place using the provided hardware. Ensure that the support is aligned correctly with the accessory drive belt and other components. Tighten all fasteners to the specified torque settings to secure the support firmly. It is important to verify that the accessory drive belt is properly tensioned and aligned after installation to ensure optimal performance.

Troubleshooting and Maintenance

To troubleshoot common issues with the Accessory Drive Support, begin by inspecting the component for signs of wear, damage, or misalignment. Ensure that all fasteners are secure and that the accessory drive belt is properly tensioned. Regular maintenance, including periodic inspections and cleaning, can help to prevent issues and ensure the longevity of the support. It is also advisable to follow the manufacturer’s recommendations for maintenance intervals and procedures.

Common Failures and Solutions

Common failure modes for the Accessory Drive Support may include cracking, corrosion, or misalignment. Addressing these issues promptly is important to prevent further damage to the accessory drive system. Solutions may involve repairing or replacing damaged components, ensuring proper alignment, and applying protective coatings to prevent corrosion. Timely maintenance and repairs are crucial to maintaining the performance and reliability of the accessory drive system.

Cummins: A Brief Overview

Cummins is a renowned manufacturer with a long-standing reputation for producing high-quality automotive components. The company has a history of innovation and commitment to excellence in the heavy-duty truck industry. Cummins’ products are known for their durability, reliability, and performance, making them a preferred choice for truck manufacturers and operators alike. The company’s dedication to quality and customer satisfaction has solidified its position as a leader in the automotive components market.

Accessory Drive Support Part 5416815 in Cummins Engines

The Accessory Drive Support part 5416815, manufactured by Cummins, is a critical component in several of their engine models. This part plays a pivotal role in maintaining the alignment and operational integrity of the engine’s accessories.

QSK60 and CM850 Engines

In the QSK60 and CM850 engines, the Accessory Drive Support part 5416815 is integral to the engine’s accessory drive system. This system includes components such as the alternator, water pump, and air conditioning compressor, which are essential for the engine’s operation and overall vehicle functionality. The support part ensures that these accessories are correctly positioned and securely fastened, thereby preventing misalignment and potential damage.

MCRS Engines

For the MCRS engines, the Accessory Drive Support part 5416815 is similarly crucial. These engines, often used in heavy-duty applications, require robust and reliable accessory drive systems to handle the demanding operational conditions. The support part in these engines helps maintain the precise alignment of the engine’s accessories, ensuring efficient power transfer and reducing wear and tear on the components.

Grouping of Engines

The Accessory Drive Support part 5416815 is designed to fit seamlessly into the accessory drive systems of the QSK60, CM850, and MCRS engines. These engines, while differing in their specific applications and power outputs, share common design principles in their accessory drive systems. The part’s compatibility across these engines underscores its versatility and importance in maintaining the operational efficiency of Cummins’ engine lineup.

Role of Part 5416815 Accessory Drive Support in Engine Systems

The Accessory Drive Support, identified by part number 5416815, is an integral component in the orchestration of various engine systems. It provides a stable mounting platform for accessories that are driven by the engine’s crankshaft.

Integration with the Drive System

In the drive system, the Accessory Drive Support is responsible for securing accessories like the alternator, air conditioning compressor, and power steering pump. It ensures these components are properly aligned with the engine’s crankshaft pulley, allowing for efficient power transfer. The support’s robust construction minimizes vibrations and ensures smooth operation, which is essential for the longevity and performance of the drive components.

Contribution to the Fuel Pump System

While the Accessory Drive Support does not directly interact with the fuel pump, its role in maintaining the stability and alignment of the drive system indirectly supports the fuel pump’s operation. A well-aligned drive system ensures that the engine runs smoothly, which in turn allows the fuel pump to deliver consistent fuel pressure to the engine. This consistency is vital for optimal combustion and overall engine efficiency.

Conclusion

In summary, the Accessory Drive Support is a foundational element that enhances the reliability and performance of interconnected engine systems, including the drive and fuel pump components. Its role in maintaining the alignment and stability of the accessory drive system is crucial for the efficient operation of heavy-duty trucks. Regular maintenance and timely repairs are essential to ensure the longevity and performance of this critical component.

-

Denton, T., & Pells, H. (2022). Automotive Technician Training Theory. Routledge.

↩ -

Sobey, E. (2009). A Field Guide to Automotive Technology. Chicago Review Press.

↩ -

Crolla, D. (2015). Crolla Encyclopedia. Wiley.

↩ -

Goodnight, N., & Van Gelder, K. (2018). Automotive Braking Systems. Jones & Bartlett Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.