This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Actuator Bracket 3002770 is a component designed by Cummins for use in commercial trucks. It serves a specific function within the truck’s actuation system, contributing to the overall operation and efficiency of the vehicle. Understanding its purpose and role is fundamental for maintaining and optimizing truck performance.

Basic Concepts of Actuator Brackets

An actuator bracket is a structural component that supports and positions an actuator within a truck’s system. It facilitates the interaction between the actuator and other mechanical parts, ensuring precise and reliable operation. The bracket’s design allows for the efficient transfer of motion and force, which is crucial for the actuation system’s functionality 1.

Purpose of the Actuator Bracket

The Actuator Bracket is integral to the actuation system of a truck. It provides a secure mounting point for the actuator, enabling it to perform its function effectively. This bracket plays a role in ensuring that the actuator can move and operate within the specified parameters, contributing to the truck’s overall performance and reliability 2.

Key Features

The Actuator Bracket is characterized by several key features that enhance its performance. It is constructed from durable materials, ensuring longevity and resistance to wear and tear. The design incorporates precise engineering to facilitate easy installation and compatibility with the actuator it supports. Additionally, the bracket may include features such as corrosion resistance and vibration damping, which contribute to its reliability in demanding truck environments 3.

Benefits

The advantages of using the Actuator Bracket include improved efficiency, durability, and reliability in truck operations. Its robust construction and precise design contribute to the smooth and consistent operation of the actuation system. This, in turn, can lead to enhanced truck performance, reduced maintenance needs, and increased operational uptime 4.

Installation Process

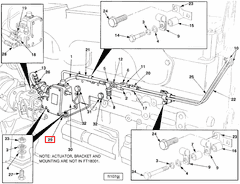

Installing the Actuator Bracket requires careful attention to detail to ensure proper functionality. The process involves securing the bracket in the designated location, aligning it with the actuator, and ensuring all connections are tight and secure. It is important to follow manufacturer guidelines to avoid potential issues and ensure the bracket operates as intended 5.

Common Issues and Troubleshooting

Typical problems associated with the Actuator Bracket may include misalignment, wear, or damage. Troubleshooting these issues involves inspecting the bracket for signs of damage, ensuring it is properly aligned with the actuator, and checking all connections for tightness. Addressing these issues promptly can help maintain the efficiency and reliability of the actuation system 6.

Maintenance Tips

Regular maintenance practices are recommended to ensure the longevity and optimal performance of the Actuator Bracket. This includes periodic inspections for signs of wear or damage, ensuring all connections remain tight, and addressing any issues as they arise. Additionally, keeping the bracket clean and free from debris can contribute to its longevity and performance 7.

Cummins Overview

Cummins is a well-established company in the commercial truck industry, known for its wide range of products and strong reputation for quality and reliability. With a history of innovation and commitment to excellence, Cummins continues to be a leading provider of components and systems for commercial trucks, including the Actuator Bracket.

Compatibility with Cummins Engines

The Actuator Bracket is designed to be a versatile component that fits seamlessly with a variety of engine models. This bracket is engineered to provide stability and support to the actuator, ensuring optimal performance and longevity of the engine systems it is integrated with.

K-Series Engines

The K19, K38, and K50 engines are part of Cummins’ K-Series lineup, known for their robust design and reliability. The Actuator Bracket is specifically engineered to fit these engines, providing a secure mounting point for the actuator. This ensures that the actuator can operate without undue stress, contributing to the overall efficiency and durability of the engine.

N-Series Engines

The N14 MECHANICAL engine, part of Cummins’ N-Series, is another model that benefits from the Actuator Bracket. This bracket is designed to align perfectly with the actuator’s mounting points on the N14 MECHANICAL, ensuring precise operation and reducing the risk of misalignment or wear over time.

NH/NT 855 Engines

The NH/NT 855 engines, which are part of Cummins’ NT855 series, also utilize the Actuator Bracket. This bracket is engineered to fit the specific design and requirements of these engines, providing a reliable mounting solution that enhances the actuator’s performance and extends the engine’s operational life.

V-Series Engines

The V28 engine, part of Cummins’ V-Series, is another model that is compatible with the Actuator Bracket. This bracket is designed to fit the unique configuration of the V28, ensuring that the actuator is securely mounted and can operate efficiently within the engine’s design parameters.

By providing a precise fit and reliable support, the Actuator Bracket is an essential component for maintaining the performance and longevity of these diverse engine models.

Role of the Actuator Bracket in Engine Systems

The Actuator Bracket, identified by part number 3002770, is an integral component in the assembly and operation of various engine systems. Its primary function is to provide a secure mounting point for the actuator, ensuring stability and precise control over the engine’s accessory drive mechanisms.

Integration with Accessory Drive Systems

In accessory drive systems, the Actuator Bracket is responsible for mounting the actuator, which in turn controls the engagement and disengagement of accessories such as the fuel pump and other driven components. This bracket ensures that the actuator remains firmly in place, allowing for smooth and reliable operation of the accessory drive.

Fuel Pump and Accessory Drive

When considering the fuel pump and accessory drive, the Actuator Bracket plays a significant role in maintaining the structural integrity of the system. It supports the actuator that manages the fuel pump’s operation, ensuring consistent fuel supply to the engine. The bracket’s robust design helps in withstanding the vibrations and stresses inherent in engine operation.

Governor and Tail Shaft Mechanisms

In systems involving the American Bosch Governor and tail shaft, the Actuator Bracket is essential for accurate governor function. It mounts the actuator that modulates the governor’s input, directly influencing the engine’s speed and performance. The precise mounting provided by the bracket ensures that the governor can respond accurately to changes in engine load and speed.

Fuel Supply and Plumbing

For fuel supply and plumbing components, the Actuator Bracket supports the actuator that controls the fuel tubing and overall fuel supply system. This ensures that the fuel pump operates efficiently, providing a steady fuel flow to the engine. The bracket’s design facilitates easy maintenance and adjustment of the actuator, enhancing the system’s reliability.

Non-AFC Auto Fuel Pump Systems

In non-AFC auto fuel pump systems, the Actuator Bracket is vital for mounting the actuator that regulates the fuel pump’s operation. Whether paired with an American Bosch Governor or another type, the bracket ensures that the actuator functions correctly, maintaining optimal fuel delivery to the engine.

Overall System Stability

Across all these applications, the Actuator Bracket (part 3002770) contributes to the overall stability and efficiency of the engine system. By providing a solid mounting solution for the actuator, it enables precise control over various engine components, ensuring they operate harmoniously and efficiently.

Conclusion

The Actuator Bracket 3002770 by Cummins is a critical component in the operation and maintenance of commercial truck engines. Its role in providing a secure mounting point for actuators ensures the efficient and reliable operation of various engine systems. Understanding its features, benefits, and proper maintenance can significantly contribute to the longevity and performance of the truck’s engine.

-

Trzesniowski, M. (2023). The Complete Vehicle. Springer Nature.

↩ -

Harrison, M. (2004). Controlling Noise and Vibration in Road Vehicles. SAE International.

↩ -

Lakshminarayanan, P. A., & Agarwal, A. K. (2019). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer.

↩ -

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for QSZ13 CM2150 Z102. Bulletin Number 4358370.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for QSZ13 CM2150 Z102. Bulletin Number 4358370.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for QSZ13 CM2150 Z102. Bulletin Number 4358370.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.