This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Actuator Plunger 3026070, manufactured by Cummins, is a component that plays a role in the operation of commercial trucks. Cummins, a well-established name in the commercial truck industry, produces a range of parts designed to enhance the performance and reliability of truck systems. The Actuator Plunger 3026070 is one such part, integral to the efficient functioning of truck engines.

Basic Concepts of Actuator Plungers

An actuator plunger is a mechanical component that converts electrical signals into physical movements. It operates within various systems by using hydraulic or pneumatic pressure to move a plunger, which in turn activates other mechanisms. In automotive applications, actuator plungers are commonly used in fuel injection systems, braking systems, and other control mechanisms where precise movement is required 1.

Role of the 3026070 Actuator Plunger in Truck Operation

This Cummins part is specifically designed to function within the fuel injection system of a truck. It interacts with the engine control unit (ECU) to regulate the amount of fuel injected into the engine cylinders. This regulation is important for maintaining optimal engine performance, fuel efficiency, and emissions control. The plunger’s precise movements ensure that fuel is delivered at the correct time and in the correct quantity, contributing to the overall efficiency and reliability of the truck’s operation 2.

Key Features of the 3026070 Actuator Plunger

The 3026070 Actuator Plunger is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials that resist wear and corrosion, ensuring longevity in demanding truck environments. The plunger is precision-engineered to provide accurate and consistent movements, which is vital for the precise fuel delivery required by modern truck engines. Additionally, its design incorporates features that reduce friction and wear, further contributing to its reliability and efficiency.

Benefits of Using the 3026070 Actuator Plunger

Utilizing this part in truck operations offers several benefits. Its precise fuel delivery capabilities contribute to improved engine performance and fuel efficiency. The plunger’s durable construction and reliable operation reduce the likelihood of system failures, leading to increased uptime and reduced maintenance costs. Furthermore, the enhanced fuel efficiency and emissions control provided by the plunger contribute to a truck’s overall environmental performance.

Troubleshooting Common Issues with Actuator Plungers

Common issues with actuator plungers may include inconsistent fuel delivery, plunger sticking, or electrical faults. Identifying these problems often involves monitoring the truck’s performance and fuel efficiency. Diagnostic tools can help pinpoint electrical issues, while physical inspection can reveal signs of wear or damage. Addressing these issues may involve cleaning or lubricating the plunger, repairing electrical connections, or, in some cases, replacing the plunger.

Maintenance Practices for Actuator Plungers

Regular maintenance of the 3026070 Actuator Plunger is key to ensuring its longevity and optimal performance. This includes periodic inspection for signs of wear, corrosion, or damage. Cleaning the plunger and its surrounding components can prevent buildup that may affect its operation. Additionally, ensuring that the electrical connections are secure and free from corrosion is important for the plunger’s reliable operation. Following the manufacturer’s maintenance guidelines can help maximize the lifespan and efficiency of the actuator plunger.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s extensive product range and commitment to customer satisfaction have made it a preferred choice for truck manufacturers and operators worldwide 3.

Role of Part 3026070 Actuator Plunger in Engine Systems

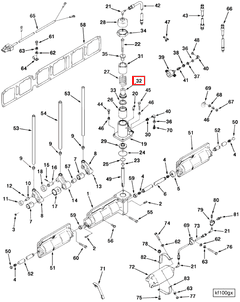

The Actuator Plunger, identified by part number 3026070, is an integral component in the orchestration of various engine systems. Its primary function is to facilitate the precise movement and control within the engine’s actuator system.

When the solenoid valve is energized, it creates a magnetic field that pulls the Actuator Plunger into motion. This movement is transferred through the base parts, ensuring a smooth and controlled operation. The Plunger’s motion is further refined as it interacts with the cam follower assembly and the cam follower housing. This interaction allows for the modulation of engine functions, such as fuel injection timing or valve operation, depending on the specific engine system in use.

The Actuator Plunger also plays a role in conjunction with the master cam follower and its housing. As the Plunger moves, it engages with the master cam follower, which is housed within its designated housing. This engagement is vital for the accurate timing and sequencing of engine operations. The master cam follower housing ensures that the master cam follower remains in the correct position, allowing for consistent and reliable engine performance.

Conclusion

In summary, the Actuator Plunger (part 3026070) is a key player in the engine’s actuation system, working in harmony with the solenoid valve, base parts, cam follower assembly, cam follower housing, and the master cam follower with its housing to ensure the engine operates efficiently and effectively.

-

Dixon, John C. Tyres Suspension and Handling Second Edition. SAE International, 1996.

↩ -

Hu, Haoran, Rudy Smaling, and Simon Baseley. Heavy-Duty Wheeled Vehicles. SAE International, 2014.

↩ -

Reif, Konrad, ed. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.