This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

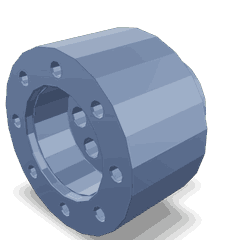

The Cummins 3092012 Crankshaft Adapter is a specialized component designed for use in heavy-duty trucks. Its purpose is to facilitate the connection between the crankshaft and other engine components, ensuring smooth operation and efficient power transmission. The significance of this adapter lies in its ability to enhance the overall performance and reliability of the engine system in demanding applications.

Basic Concepts of Crankshaft Adapters

A crankshaft adapter serves as an intermediary component that connects the crankshaft to various engine parts, such as sensors, balancers, or other accessories. Its general function is to provide a secure and precise interface, allowing for the accurate transfer of rotational force and data. By integrating with other components, the crankshaft adapter plays a role in maintaining the engine’s balance, monitoring performance metrics, and ensuring the smooth operation of connected systems 1.

Purpose of the 3092012 Crankshaft Adapter

The Cummins 3092012 Crankshaft Adapter is specifically designed to interface with the crankshaft in heavy-duty truck engines. Its role within the engine system includes providing a stable connection point for sensors and other accessories, which are crucial for monitoring engine performance and ensuring optimal operation. By facilitating these connections, the adapter contributes to the engine’s efficiency, reliability, and overall functionality.

Key Features

The Cummins 3092012 Crankshaft Adapter boasts several key features that enhance its performance and durability. These include a robust material composition, typically consisting of high-strength alloys that can withstand the rigors of heavy-duty applications. The design elements of the adapter are engineered to provide a precise fit and secure connection, minimizing the risk of misalignment or failure. Additionally, unique attributes such as corrosion-resistant coatings and precision machining contribute to its longevity and reliability in demanding environments.

Benefits

The Cummins 3092012 Crankshaft Adapter offers several benefits that contribute to improved engine performance and durability. By providing a stable and precise connection between the crankshaft and other components, it helps ensure accurate data transmission and efficient power transfer. This results in enhanced engine reliability, reduced wear on connected parts, and overall improved performance. Furthermore, the adapter’s durable construction and resistance to corrosion contribute to its longevity, making it a valuable component in heavy-duty truck engines.

Installation Process

Proper installation of the Cummins 3092012 Crankshaft Adapter is crucial for ensuring its effectiveness and longevity. The process involves several steps, including preparing the engine for installation, aligning the adapter with the crankshaft, and securing it in place using the appropriate tools and equipment. Important considerations during installation include ensuring a clean and debris-free installation area, using the correct torque specifications for fastening components, and verifying the alignment and fit of the adapter to prevent issues such as misalignment or loose connections.

Common Issues and Troubleshooting

Common issues that may arise with the Cummins 3092012 Crankshaft Adapter include misalignment, loose connections, and corrosion. Troubleshooting these problems effectively involves inspecting the adapter and surrounding components for signs of wear or damage, ensuring proper alignment and fit, and addressing any corrosion with appropriate cleaning and protective measures. Solutions may include re-torquing fasteners, replacing worn or damaged parts, and applying corrosion-resistant coatings to prevent future issues.

Maintenance Tips

To ensure optimal performance and longevity of the Cummins 3092012 Crankshaft Adapter, regular maintenance is recommended. This includes periodic inspection of the adapter and connected components for signs of wear, corrosion, or misalignment. Cleaning the adapter and surrounding areas to remove debris and contaminants is also important. Additionally, applying corrosion-resistant coatings or lubricants can help protect the adapter from environmental factors and extend its service life. Following these maintenance practices will help maintain the adapter’s effectiveness and contribute to the overall reliability of the engine system.

Cummins Overview

Cummins Inc. is a renowned manufacturer with a rich history in the production of high-quality automotive components. Established in 1919, the company has built a reputation for innovation, reliability, and excellence in the industry. Cummins is committed to delivering superior products that meet the demanding requirements of heavy-duty applications, ensuring customers receive components that enhance performance, durability, and efficiency in their vehicles.

Crankshaft Adapter 3092012 Compatibility with Cummins Engines

The Crankshaft Adapter 3092012, manufactured by Cummins, is designed to fit seamlessly with a range of Cummins engines. Specifically, this adapter is compatible with the following engine models:

- QST30 CM2350 T101

- QST30 CM552

This adapter plays a role in ensuring the proper alignment and functionality of the crankshaft within these engines. Its design allows for precise fitting and secure attachment, which is essential for maintaining engine performance and longevity.

For the QST30 CM2350 T101 and QST30 CM552 engines, the adapter ensures that the crankshaft is correctly positioned relative to other engine components, facilitating smooth operation and reducing the risk of mechanical failure. The compatibility of the 3092012 adapter with these specific engine models underscores its importance in the overall engine assembly and maintenance process.

Role of Part 3092012 Crankshaft Adapter in Engine Systems

The Part 3092012 Crankshaft Adapter is a component in the integration and functionality of various engine systems. It serves as an interface that connects the crankshaft to other critical assemblies within the engine.

Integration with Vibration Dampers

In engine systems, the crankshaft adapter works in conjunction with the vibration damper. The vibration damper is designed to absorb and reduce the torsional vibrations generated by the engine’s operation. The crankshaft adapter ensures a secure and precise fit between the crankshaft and the vibration damper, allowing for efficient transfer of rotational energy while minimizing vibrations that could lead to mechanical wear or failure.

Interaction with the Top-Level Assembly

At the top level of the engine assembly, the crankshaft adapter plays a role in maintaining the structural integrity and alignment of components. It interfaces with the vibration damper, which is often part of the top-level assembly, to ensure that the entire system operates smoothly. This integration helps in maintaining the balance and stability of the engine, reducing the likelihood of misalignments that could affect performance.

Contribution to Overall Engine Arrangement

The crankshaft adapter is integral to the overall arrangement of engine components. It facilitates the proper alignment of the crankshaft with other parts, such as the flywheel and the harmonic balancer. This alignment is vital for the efficient operation of the engine, ensuring that all moving parts work in harmony to deliver optimal performance.

By providing a stable and reliable connection point, the crankshaft adapter enhances the durability and efficiency of the engine system, allowing for smoother operation and reduced maintenance requirements.

Conclusion

The Cummins 3092012 Crankshaft Adapter is a critical component in the operation and maintenance of heavy-duty truck engines. Its robust design, precise fitting, and compatibility with specific Cummins engine models ensure that it plays a vital role in maintaining engine performance and longevity. Regular maintenance and proper installation are essential to maximize the benefits of this Cummins part, contributing to the overall reliability and efficiency of the engine system.

-

Martyr, A.J. Engine Testing: Theory and Practice: Third Edition. SAE International, 2007.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.