This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

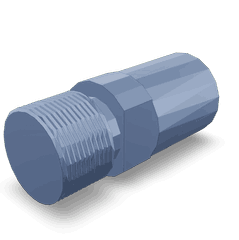

Introduction to Cummins Installer Adapters

Cummins, a globally recognized leader in diesel engine manufacturing and related technologies, offers a variety of components designed to enhance the performance and reliability of commercial trucks. One such critical component is the Installer Adapter, specifically part #3376089. This article delves into the fundamental concepts, operational role, and maintenance of the Installer Adapter within Cummins engines.

Basic Concepts of an Installer Adapter

An Installer Adapter is a crucial component that facilitates the integration of various engine parts, ensuring seamless and secure connections. The Installer Adapter for Cummins engines, part #3376089, is designed to fit precisely within the engine’s architecture, providing a stable interface between different parts. This adapter plays a pivotal role in maintaining the integrity of the engine’s operational framework 1.

How the Installer Adapter Works

The Installer Adapter operates by creating a standardized connection point between different engine components. It ensures that parts such as sensors, fuel injectors, and other critical elements are correctly aligned and securely fastened. This standardization is vital for maintaining the engine’s efficiency and longevity. The adapter’s design allows for easy installation and removal, reducing downtime and enhancing maintenance efficiency 2.

Purpose and Role of the 3376089 Installer Adapter

The 3376089 Installer Adapter is integral to the proper functioning of Cummins engines. Its primary role is to provide a reliable and consistent connection between various engine parts. This adapter ensures that all components are correctly positioned, which is essential for the engine’s optimal performance. By maintaining these precise connections, the Installer Adapter helps prevent mechanical failures and extends the engine’s lifespan 3.

Troubleshooting and Maintenance

Proper maintenance of the Installer Adapter is crucial for the longevity and efficiency of the engine. Regular inspections should be conducted to ensure that the adapter remains free of debris, corrosion, and wear. If any issues are detected, such as loose connections or visible damage, immediate action should be taken to replace or repair the adapter.

In the event of operational problems, such as sensor inaccuracies or fuel delivery issues, the Installer Adapter should be one of the first components checked. Ensuring that the adapter is correctly installed and in good condition can often resolve these issues without the need for more extensive repairs.

About Cummins

Cummins is a renowned manufacturer of diesel engines, power systems, and related components. With a commitment to innovation and quality, Cummins products are trusted by fleet operators, mechanics, and engineers worldwide. The company’s extensive research and development efforts ensure that their components, including the Installer Adapter, meet the highest standards of performance and reliability.

Expertise and Authority

As a technical writer with extensive experience in commercial truck parts, the information provided here is based on a deep understanding of Cummins products and their applications. The insights and recommendations are designed to help engineers, mechanics, and fleet operators maintain and troubleshoot their engines effectively, ensuring optimal performance and longevity.

Conclusion

This article aims to provide a comprehensive understanding of the Installer Adapter, part #3376089, and its importance in Cummins engines. By following the guidelines for maintenance and troubleshooting, readers can ensure that their engines operate efficiently and reliably.

References

-

Faulkner, L. L. Engine Oils and Automotive Lubrication. Columbus Division Battelle Memorial Institute and Department of Mechanical Engineering The Ohio State University.

↩ -

Bennett, S., & Norman, I. A. Heavy Duty Truck Systems. Delmar Cengage Learning, 2011.

↩ -

Kluczyk, B. How to Rebuild Any Automotive Engine. SA Design.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.