This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

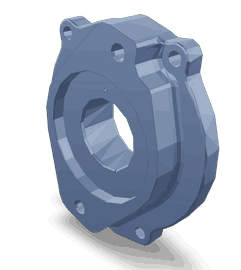

The Cummins 3681379 Hydraulic Pump Adapter is a component designed for use in the hydraulic systems of commercial trucks. Its purpose is to facilitate the connection and regulation of hydraulic fluid flow within these systems, ensuring efficient operation of hydraulic components such as brakes, steering, and suspension systems 1.

Basic Concepts of Hydraulic Pump Adapters

Hydraulic systems in trucks utilize fluid power to perform mechanical tasks. These systems consist of a pump, fluid reservoir, valves, and actuators. Hydraulic pump adapters play a role in these systems by providing a connection point between the pump and the hydraulic lines, allowing for the transfer of hydraulic fluid. They also help in regulating the flow and pressure of the fluid, which is crucial for the proper functioning of hydraulic components 2.

Purpose of the Cummins 3681379 Hydraulic Pump Adapter

This Cummins part serves a specific role in the operation of a truck’s hydraulic system. It connects the hydraulic pump to the rest of the hydraulic system, enabling the flow of hydraulic fluid. This adapter also plays a part in regulating the fluid flow, ensuring that the hydraulic components receive the correct amount of fluid at the appropriate pressure. This regulation is vital for the efficient and reliable operation of the truck’s hydraulic systems 3.

Key Features

The Cummins 3681379 is constructed from durable materials, ensuring it can withstand the pressures and conditions within a truck’s hydraulic system. Its design includes features that enhance its performance and durability, such as precision-machined ports for optimal fluid flow and robust construction to resist wear and corrosion. These attributes contribute to the adapter’s reliability and longevity in demanding applications.

Benefits

The use of the Cummins 3681379 offers several advantages. It contributes to improved efficiency within the hydraulic system by ensuring smooth and regulated fluid flow. Its reliable construction enhances the overall reliability of the hydraulic system, reducing the likelihood of failures. Additionally, the adapter is designed to be compatible with various hydraulic systems, making it a versatile choice for different truck models and applications.

Installation and Integration

Proper installation of the Cummins 3681379 is crucial for its effective operation. This process involves connecting the adapter to the hydraulic pump and the hydraulic lines, ensuring all connections are secure and leak-free. It may also require the alignment of the adapter with other components to ensure optimal fluid flow. Careful consideration of the system’s specifications and the adapter’s design is necessary to achieve a successful integration.

Troubleshooting and Maintenance

Common issues with hydraulic pump adapters can include leaks, blockages, or malfunctions due to wear or debris. Troubleshooting these issues involves checking all connections for leaks, ensuring the adapter is properly aligned and installed, and inspecting for signs of wear or damage. Regular maintenance practices, such as cleaning the adapter and inspecting for wear, can help ensure its longevity and optimal performance.

Safety Considerations

When working with hydraulic systems and the Cummins 3681379, it is important to observe safety practices. This includes handling hydraulic fluids with care, as they can be hazardous if not managed properly. Additionally, performing maintenance tasks requires attention to safety protocols to prevent injuries from high-pressure fluid or moving components. Always refer to the manufacturer’s guidelines for safe operation and maintenance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. Its product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial applications. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name in the industry.

Cummins Hydraulic Pump Adapter 3681379 in Engine Applications

The Cummins Hydraulic Pump Adapter 3681379 is a critical component designed to interface with various Cummins engine models, ensuring seamless integration and optimal performance. This adapter is meticulously engineered to meet the stringent demands of modern diesel engines, providing a reliable connection between the hydraulic pump and the engine’s internal systems.

ISX CM570 Engine

The ISX CM570 engine is a robust and high-performance model within Cummins’ lineup, known for its exceptional power and efficiency. The Hydraulic Pump Adapter 3681379 is specifically tailored to fit this engine, facilitating the smooth transfer of hydraulic fluid. This ensures that the engine’s hydraulic systems operate without interruption, maintaining the integrity of critical functions such as fuel injection and variable geometry turbocharger control.

Grouping of Engines

While the Hydraulic Pump Adapter 3681379 is designed for the ISX CM570, it is also compatible with other Cummins engines that share similar design parameters and hydraulic system requirements. This adaptability makes it a versatile component across various Cummins engine models, ensuring that the adapter can be utilized in multiple applications without compromising performance or reliability.

The adapter’s precision engineering guarantees a perfect fit, reducing the risk of leaks and ensuring that the hydraulic pump operates at peak efficiency. This is particularly important in heavy-duty applications where reliability and performance are paramount. The adapter’s robust construction also means it can withstand the harsh operating conditions typical of diesel engines, providing long-lasting durability and consistent performance.

Role of Part 3681379 Hydraulic Pump Adapter in Engine Systems

The Hydraulic Pump Adapter, part 3681379, is an essential component in the integration of various engine systems, ensuring seamless operation and efficiency. When installed, this adapter facilitates the connection between the drive and the front gear train accessory, allowing for the efficient transfer of power and fluid dynamics necessary for the hydraulic pump’s operation.

Integration with the Drive

The drive system is responsible for transmitting power from the engine to various components. The Hydraulic Pump Adapter ensures a secure and precise connection, enabling the drive to effectively transfer rotational force. This connection is vital for maintaining the integrity and performance of the drive system, as it allows for smooth operation without energy loss.

Connection to the Front Gear Train Accessory

The front gear train accessory plays a significant role in modulating the speed and torque of the hydraulic system. The Hydraulic Pump Adapter interfaces directly with this accessory, ensuring that the hydraulic pump receives the necessary input to function correctly. This integration is important for the overall efficiency of the gear train, as it allows for precise control over the hydraulic system’s performance.

Enabling Hydraulic Pump Functionality

Once connected to the drive and the front gear train accessory, the Hydraulic Pump Adapter allows the hydraulic pump to operate efficiently. The adapter ensures that the hydraulic fluid is circulated under the correct pressure and flow rate, which is essential for the pump’s performance. This, in turn, supports the various hydraulic functions within the engine system, such as actuating components, providing lubrication, and enabling precise control over mechanical movements.

Conclusion

In summary, the Hydraulic Pump Adapter, part 3681379, plays a significant role in the coordination and efficiency of the drive, front gear train accessory, and hydraulic pump within engine systems. Its proper installation and function are important for the overall performance and reliability of the engine.

-

Asef, Pedram, Sanjeevikumar Padmanaban, and Andrew Lapthorn. Modern Automotive Electrical Systems. Wiley, 2022.

↩ -

Hu, Haoran, Rudy Smaling, and Simon Baseley. Heavy-Duty Wheeled Vehicles. SAE International, 2014.

↩ -

Denton, Tom, and Hayley Pells. Automotive Technician Training Theory. Routledge, 2022.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.