This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

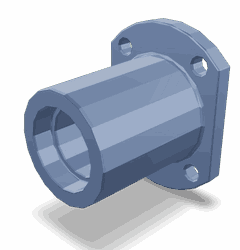

The Drive Coupling Adapter 3696588, manufactured by Cummins, is designed to enhance the efficiency and reliability of commercial truck operations. Cummins, a well-established name in the industry, produces this adapter to ensure seamless integration and optimal performance within the truck’s powertrain system.

Basic Concepts of Drive Coupling Adapters

A drive coupling adapter functions as a connector between two rotating shafts, facilitating the transfer of power and motion. Its role in mechanical systems is to join different components, allowing them to operate in unison while accommodating slight misalignments and absorbing shocks. This ensures smooth operation and reduces wear and tear on the connected parts 1.

Purpose of the 3696588 Drive Coupling Adapter

This part plays a specific role in the operation of commercial trucks by linking the engine to the transmission. This connection is vital for the efficient transfer of power from the engine to the wheels, ensuring that the truck operates smoothly and effectively. Within the powertrain system, this adapter helps maintain alignment and balance, contributing to the overall performance and durability of the truck 2.

Key Features

The 3696588 Drive Coupling Adapter is crafted from high-quality materials, ensuring durability and long-lasting performance. Its design includes precision-machined components that allow for a secure fit and reliable operation. Unique attributes such as corrosion-resistant coatings and enhanced flexibility further contribute to its performance and durability, making it suitable for the demanding conditions of commercial truck operations 3.

Benefits

The advantages provided by the 3696588 Drive Coupling Adapter include improved efficiency and reliability in the truck’s drivetrain. By ensuring a smooth transfer of power, it helps reduce energy loss and enhances the overall performance of the vehicle. Additionally, its robust design contributes to the longevity of the truck’s components, offering a reliable solution for commercial use 4.

Installation and Integration

Proper installation of the 3696588 Drive Coupling Adapter within a truck’s drivetrain system involves several steps to ensure successful integration. It is important to follow manufacturer guidelines, which may include aligning the adapter correctly, securing it with appropriate fasteners, and verifying that all connections are tight and secure. Consideration should be given to the specific requirements of the truck’s make and model to ensure compatibility and optimal performance.

Troubleshooting Common Issues

Common problems associated with drive coupling adapters can include misalignment, wear, and damage due to excessive vibration or shock. Identifying these issues early is important for maintaining the efficiency of the truck’s drivetrain. Recommended troubleshooting steps may involve inspecting the adapter for signs of wear, ensuring proper alignment, and addressing any sources of excessive vibration or shock that could affect its performance.

Maintenance Tips

To ensure the longevity and optimal performance of the 3696588 Drive Coupling Adapter, regular maintenance is recommended. This includes routine inspections to check for signs of wear or damage, cleaning the adapter to remove any debris or contaminants, and lubricating moving parts as necessary. Knowing when to consider replacement is also important, typically when significant wear is observed or if the adapter fails to function correctly despite maintenance efforts.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to quality and innovation. With a rich history of producing reliable and high-performance engines and components, Cummins has established a strong reputation for excellence. Its product range includes a variety of engines, powertrain solutions, and aftermarket parts, all designed to meet the demanding needs of commercial truck operators.

Compatibility with Cummins Engines

This Cummins part is designed to fit a variety of Cummins engine models. Here’s how it integrates with the specified engines:

ISG11 CM2880 G108 and ISG12 CM2880 G107

Both the ISG11 CM2880 G108 and ISG12 CM2880 G107 engines are part of Cummins’ lineup that utilizes the CM2880 engine series. The Drive Coupling Adapter 3696588 is engineered to fit these engines seamlessly, ensuring optimal power transmission and durability.

ISG12 G CMOH6.0 G111

The ISG12 G CMOH6.0 G111 engine is another model where the Drive Coupling Adapter 3696588 is applicable. This adapter is designed to handle the specific power dynamics and torque requirements of the CMOH6.0 engine series, ensuring that the engine operates at peak performance.

QSG12/X12 CM2350 G110

The QSG12/X12 CM2350 G110 engine is part of Cummins’ versatile QSG series. The Drive Coupling Adapter 3696588 is compatible with this engine, providing a reliable connection that supports the engine’s power output and operational demands.

X11 CM2670 X126B and X12 CM2350 X119B

The X11 CM2670 X126B and X12 CM2350 X119B engines are both equipped with the Drive Coupling Adapter 3696588. This adapter is designed to fit these engines, ensuring efficient power transfer and maintaining the integrity of the drivetrain system.

X12 CM2670 X121B

The X12 CM2670 X121B engine also benefits from the Drive Coupling Adapter 3696588. This adapter is specifically designed to integrate with the X12 series engines, providing a robust and reliable connection that supports the engine’s power and performance characteristics.

Role of Part 3696588 Drive Coupling Adapter in Engine Systems

The Drive Coupling Adapter, part number 3696588, is a component in ensuring the seamless operation of various engine systems. Its primary function is to facilitate the transfer of rotational force between different parts of the engine, thereby enhancing the overall efficiency and performance of the engine.

Integration with Flywheel Housing

In the context of the flywheel housing, the Drive Coupling Adapter acts as a mediator between the flywheel and the engine’s output shaft. This connection is vital for maintaining the balance and stability of the engine during operation. The adapter ensures that the rotational energy generated by the engine is efficiently transferred to the flywheel, which in turn helps in smoothing out the power delivery to the transmission system.

Connection to Power Takeoff Housing

When integrated with the power takeoff (PTO) housing, the Drive Coupling Adapter plays a significant role in diverting a portion of the engine’s power to auxiliary systems. This is particularly important in applications where the engine needs to power additional equipment, such as hydraulic pumps or generators. The adapter ensures a secure and efficient transfer of power, minimizing energy loss and maximizing the utility of the engine’s output.

Interaction with Rear Gear Train Accessory Drive

In systems involving the rear gear train accessory drive, the Drive Coupling Adapter is responsible for connecting the accessory drive to the main engine components. This connection is essential for driving various accessories, such as the alternator, water pump, and air conditioning compressor. The adapter ensures that these accessories receive the necessary power to function correctly, thereby contributing to the overall reliability and performance of the engine.

Conclusion

The Drive Coupling Adapter 3696588 is a key component in ensuring the smooth and efficient operation of various engine systems. Its role in facilitating the transfer of rotational force between different parts of the engine is significant, making it an indispensable part of modern engine designs.

-

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Osgood, L., Cameron, G., & Christensen, E. (2024). Engineering Mechanics: Statics. Creative Commons.

↩ -

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ -

Van Gelder, K. T. (2018). Fundamentals of Automotive Technology Principles and Practice. Jones Bartlett Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.