This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

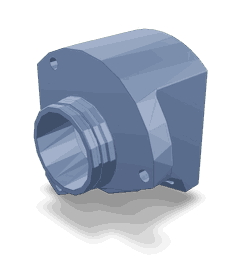

The Cummins Hydraulic Pump Adapter, part number 3925916, is a specialized component designed for use in commercial truck operations. Cummins, a well-established name in the industry, produces a wide range of parts and systems that enhance the performance and reliability of commercial vehicles. This part is integral to the hydraulic systems found in many trucks, contributing to the efficient operation of various hydraulic functions.

Basic Concepts of Hydraulic Pump Adapters

Hydraulic systems in trucks are responsible for operating various functions such as braking, steering, and lifting. These systems rely on the transfer of fluid under pressure to perform mechanical work. Hydraulic pump adapters play a role in these systems by connecting the hydraulic pump to other components, ensuring the smooth and efficient transfer of hydraulic fluid. They are designed to withstand high pressures and provide a secure connection, which is vital for the consistent performance of hydraulic operations 1.

Purpose of the Cummins Hydraulic Pump Adapter

The Cummins Hydraulic Pump Adapter is specifically designed to facilitate the connection between the hydraulic pump and other hydraulic components within a truck’s system. This adapter ensures that the hydraulic fluid is delivered efficiently to the necessary parts, allowing for the proper operation of hydraulic functions. Its integration with other hydraulic components is seamless, contributing to the overall reliability and performance of the truck’s hydraulic system.

Key Features

The Cummins Hydraulic Pump Adapter boasts several key features that enhance its performance and durability. Constructed from high-quality materials, it is designed to resist corrosion and wear, ensuring a long service life. The adapter features precise engineering, allowing for a secure and leak-free connection. Additionally, it is designed with compatibility in mind, ensuring it can be easily integrated into various hydraulic systems.

Benefits

The advantages provided by the Cummins Hydraulic Pump Adapter include improved efficiency and reliability within the hydraulic system. By ensuring a secure and consistent connection, it helps maintain the optimal performance of hydraulic functions. Furthermore, its robust construction contributes to the longevity of the component, reducing the need for frequent replacements and maintenance.

Installation and Integration

Proper installation of the Cummins Hydraulic Pump Adapter is crucial for its effective operation. It should be installed according to the manufacturer’s guidelines, ensuring all connections are secure and leak-free. Integration with the truck’s hydraulic system requires careful attention to detail, including the correct alignment and tightening of connections. Any prerequisites or considerations should be observed to ensure the adapter functions as intended.

Troubleshooting and Maintenance

Identifying common issues with the Cummins Hydraulic Pump Adapter can help maintain its performance and longevity. Regular inspections for leaks, corrosion, or wear are recommended. Maintenance practices should include cleaning the adapter and its connections, as well as checking for proper alignment and tightness. Should any issues arise, following the manufacturer’s guidelines for resolution is advised to ensure the adapter continues to operate efficiently.

Safety Considerations

When working with the Cummins Hydraulic Pump Adapter, observing important safety guidelines and precautions is vital. This includes ensuring the hydraulic system is depressurized before any work is performed to prevent injury from hydraulic fluid under pressure. Additionally, using the correct tools and following proper procedures during installation and maintenance will help ensure safety and the effective operation of the adapter.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing high-quality, reliable components. Their product range includes engines, powertrains, and aftermarket parts, all designed to enhance the performance and efficiency of commercial vehicles.

Cummins Hydraulic Pump Adapter 3925916 Compatibility

The Cummins Hydraulic Pump Adapter part number 3925916 is designed to fit a variety of Cummins engines, ensuring seamless integration and reliable performance. Here’s a detailed look at the compatibility of this adapter with different engine models:

ISC Series Engines

- ISC CM2150

- ISC CM554

- ISC CM850

- ISC8.3 CM2250

ISL Series Engines

- ISL CM2150

- ISL CM554

- ISL G CM2180

- ISL9 CM2150 SN

- ISL9 CM2250

ISM Series Engines

- ISM CM570

- ISM CM570/870

QSC and QSL Series Engines

- QSC8.3 CM554

- QSC8.3 CM850 (CM2850)

- QSC9 CM2250 / QSL9 CM2250

- QSL8.9 CM2150 L141

- QSL9 CM2250

- QSL9 CM554

- QSL9 CM850 (CM2850)

C Series Engines

- C GAS PLUS CM556

- C8.3 G

M Series Engines

- M11 CELECT

- M11 CELECT PLUS

- M11 MECHANICAL

L10 Series Engine

- L10 MECHANICAL

This adapter is engineered to ensure proper hydraulic pump functionality across these diverse engine models, providing a critical component for maintaining system efficiency and reliability.

Role of Part 3925916 Hydraulic Pump Adapter in Engine Systems

The Hydraulic Pump Adapter, identified by part number 3925916, is integral to the efficient operation of various engine systems. It facilitates the connection between the hydraulic pump and the engine, ensuring seamless fluid transfer and pressure regulation.

Integration with Flywheel Housing and Assemblies

When installed in the flywheel housing, the Hydraulic Pump Adapter ensures a secure and leak-free connection. This is particularly important in the flywheel top-level assembly housing, where precise alignment and sealing are necessary to maintain engine performance. The adapter’s design allows for easy attachment and detachment, simplifying maintenance procedures.

Function within Housing and Flywheel Components

In the context of the housing and flywheel components, the adapter plays a key role in managing hydraulic fluid flow. It interfaces directly with the flywheel, ensuring that the hydraulic system receives consistent pressure. This is essential for the operation of systems reliant on hydraulic power, such as steering or braking mechanisms.

Compatibility with Flywheel TLA and Repto Upfit

The adapter is also designed to work harmoniously with the flywheel TLA (Top-Level Assembly) and Repto upfit. These components often require specific hydraulic pressures to function correctly. The Hydraulic Pump Adapter ensures that the necessary hydraulic conditions are met, contributing to the overall reliability and performance of the engine system.

Application in Repto and Kit Assemblies

In Repto assemblies and kit configurations, the adapter serves as a vital link between the hydraulic pump and the engine. It allows for the customization and upfitting of engine systems, providing flexibility in design and application. The adapter’s robust construction ensures durability under varying operational conditions.

Overall System Contribution

Overall, the Hydraulic Pump Adapter (part 3925916) is a fundamental component in the hydraulic circuitry of engine systems. Its role in connecting, sealing, and regulating hydraulic flow is essential for the efficient and reliable operation of the engine and its associated systems.

Conclusion

The Cummins Hydraulic Pump Adapter, part number 3925916, is a critical component in the hydraulic systems of commercial trucks. Its design and features ensure efficient and reliable operation of hydraulic functions, contributing to the overall performance and durability of the vehicle. Proper installation, maintenance, and adherence to safety guidelines are essential for maximizing the benefits of this Cummins part.

-

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.