This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

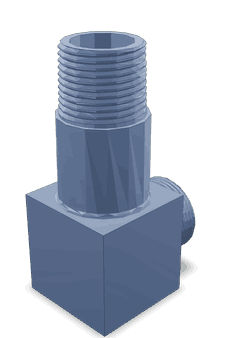

The Male Adapter Elbow, identified by Part #3930785, is a component manufactured by Cummins, a renowned name in the automotive and heavy-duty truck industry. This part is integral to the fluid transfer systems in commercial trucks, facilitating the connection between various components within the system. Cummins, known for its commitment to quality and innovation, produces this adapter to ensure reliable and efficient operation in demanding environments 1.

Basic Concepts and Functionality

A Male Adapter Elbow is a fitting used to join two pipes or hoses at an angle, allowing for a change in direction within a fluid transfer system. It operates by providing a secure connection point that can withstand the pressures and temperatures typical in truck systems. This adapter is designed to connect different components, ensuring that fluids such as fuel, coolant, or hydraulic fluid are transferred efficiently and without leaks 2.

Purpose of the Male Adapter Elbow

The Male Adapter Elbow (Part #3930785) serves a specific role in the operation of a truck by enabling the transfer of fluids between components that are not aligned in a straight line. Its function is vital in systems where space constraints or design requirements necessitate a change in the direction of fluid flow. This adapter ensures that the fluid transfer is smooth and uninterrupted, contributing to the overall efficiency and reliability of the truck’s system 3.

Key Features

The Male Adapter Elbow is characterized by several key features that enhance its performance and durability. It is typically made from high-quality materials that can resist corrosion and wear, ensuring long-term reliability. The design specifications of this adapter include precise threading and fitting dimensions to ensure a secure connection. Additionally, it may feature unique attributes such as reinforced walls or specialized coatings to further enhance its durability and resistance to the elements.

Benefits

Utilizing the Male Adapter Elbow in truck systems offers several advantages. Its design contributes to efficient fluid transfer by minimizing resistance and ensuring a smooth flow. The durability of the materials used means it can withstand the rigors of commercial truck operation, reducing the need for frequent replacements. Furthermore, the adapter is designed for ease of installation, allowing for quick and secure fitting without the need for specialized tools.

Installation and Usage

Proper installation of the Male Adapter Elbow is crucial for ensuring a secure fit and optimal performance. Before installation, it is important to ensure that the mating surfaces are clean and free from debris. The use of thread sealant or tape can enhance the seal, preventing leaks. Tools required may include a wrench for tightening and a torque wrench to ensure the correct tightening specification is met. Following the manufacturer’s guidelines for installation will help ensure a secure and leak-free connection.

Troubleshooting and Maintenance

Common issues with the Male Adapter Elbow may include leaks, corrosion, or damage from wear and tear. Regular inspection for signs of wear, corrosion, or leaks is recommended to identify potential problems early. Maintenance practices such as cleaning the fitting surfaces and replacing worn or damaged adapters can prolong the lifespan and ensure optimal performance. Diagnostic tips include checking for proper alignment and secure fitting to prevent leaks.

Safety Considerations

When handling and working with the Male Adapter Elbow, it is important to follow safety guidelines to protect both the operator and the equipment. Personal protective equipment, such as gloves and safety glasses, should be worn to prevent injury from sharp edges or leaking fluids. Operational safety practices include ensuring that the system is depressurized before beginning work and following proper procedures for tightening fittings to avoid over-tightening, which can lead to damage.

Cummins Overview

Cummins is a leading manufacturer in the automotive and heavy-duty truck industry, with a history of innovation and commitment to quality. The company has established a reputation for producing reliable and high-performance components, including the Male Adapter Elbow. Cummins’ dedication to research and development ensures that their products meet the demanding requirements of commercial truck operations, providing customers with components that offer durability, efficiency, and ease of use.

Role of Part 3930785 Male Adapter Elbow in Engine Systems

The part 3930785 Male Adapter Elbow is instrumental in facilitating the efficient operation of various engine systems. In the context of the Compressor Coolant System, this component ensures a secure and reliable connection between different sections of the plumbing, allowing for the smooth transfer of coolant. Its design enables it to adapt to varying pipe orientations, which is essential in complex engine arrangements where space and routing are constrained.

In the Plumbing System, the Male Adapter Elbow plays a significant role by providing a necessary change in direction for the coolant flow. This is particularly important in densely packed engine compartments where direct routing is not feasible. The adapter allows engineers and mechanics to navigate around other components without compromising the integrity of the coolant pathway.

Furthermore, the integration of the Male Adapter Elbow in the Compressor Coolant Arrangement enhances the overall reliability and maintenance accessibility of the system. By enabling easier access to critical junctions, it simplifies the process of inspections and repairs, thereby contributing to the longevity and performance of the engine system.

Conclusion

The Male Adapter Elbow, Part #3930785, is a critical component in the fluid transfer systems of commercial trucks and engines. Its role in ensuring efficient and reliable fluid transfer, combined with its durability and ease of installation, makes it an essential part for maintaining the performance and longevity of truck and engine systems. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

-

Atkins, Richard D. An Introduction to Engine Testing and Development. SAE International, 2009.

↩ -

Robert Bosch GmbH. Bosch Automotive Handbook 9th Edition. Robert Bosch GmbH, 2014.

↩ -

Reif, Konrad Ed. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.