This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

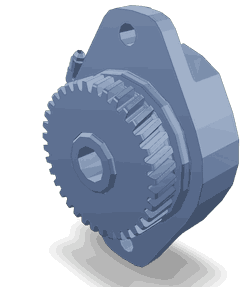

The Cummins 3939963 Hydraulic Pump Adapter is a component designed for use in the hydraulic systems of commercial trucks. Its purpose is to facilitate the connection between the hydraulic pump and other system components, ensuring the efficient transfer of hydraulic fluid. This adapter plays a role in maintaining the integrity and performance of the truck’s hydraulic system by providing a secure and reliable interface for fluid flow 1.

Basic Concepts of Hydraulic Pump Adapters

Hydraulic systems in commercial trucks are integral to various operations, including braking, steering, and the operation of auxiliary equipment. These systems rely on the movement of hydraulic fluid under pressure to perform work. Hydraulic pump adapters serve as connectors within these systems, linking the pump to other components such as hoses, valves, and reservoirs. They ensure that hydraulic fluid is directed correctly and efficiently throughout the system, contributing to the overall functionality and reliability of the truck’s hydraulic operations 2.

Purpose of the Cummins 3939963 Hydraulic Pump Adapter

The Cummins 3939963 Hydraulic Pump Adapter is specifically designed to connect and facilitate the flow of hydraulic fluid within a truck’s hydraulic system. By providing a secure connection point, it enables the hydraulic pump to deliver fluid to various parts of the system, ensuring that all hydraulic components receive the necessary pressure and flow to operate effectively. This adapter plays a role in maintaining the system’s efficiency and reliability by ensuring a consistent and uninterrupted flow of hydraulic fluid 3.

Key Features

The Cummins 3939963 Hydraulic Pump Adapter is characterized by several key features that enhance its performance and durability. Its design is engineered to provide a secure and leak-proof connection, ensuring that hydraulic fluid is efficiently transferred without loss. The adapter is constructed from high-quality materials that are resistant to corrosion and wear, contributing to its longevity. Additionally, it may feature unique attributes such as precision machining and robust sealing mechanisms to further ensure its reliability and effectiveness in demanding commercial truck applications 4.

Benefits

The Cummins 3939963 Hydraulic Pump Adapter offers several benefits that contribute to the overall performance of a truck’s hydraulic system. By ensuring a secure and efficient connection, it helps to maintain system pressure and fluid flow, leading to improved operational efficiency. Its durable construction and reliable performance enhance the system’s reliability, reducing the likelihood of leaks or failures. Furthermore, the adapter’s design may contribute to easier maintenance and replacement, facilitating the ongoing care of the hydraulic system .

Installation and Compatibility

Proper installation of the Cummins 3939963 Hydraulic Pump Adapter is vital to ensure its effective operation within the truck’s hydraulic system. Installation guidelines typically include preparing the connection points, ensuring cleanliness and compatibility with existing system components, and following manufacturer recommendations for torque settings and sealing procedures. Careful attention to these steps helps to ensure a secure and effective fit, contributing to the adapter’s performance and the overall reliability of the hydraulic system .

Troubleshooting and Maintenance

Common issues with hydraulic pump adapters may include leaks, connection failures, or wear and tear over time. Troubleshooting these issues often involves inspecting the adapter and connection points for signs of damage or wear, ensuring proper sealing, and checking for correct installation. Regular maintenance practices, such as cleaning and inspecting the adapter for signs of corrosion or damage, can help to ensure its longevity and optimal performance. Additionally, following manufacturer guidelines for maintenance and replacement can contribute to the continued efficiency and reliability of the truck’s hydraulic system .

Safety Considerations

When working with hydraulic systems and the Cummins 3939963 Hydraulic Pump Adapter, it is important to observe several safety practices and precautions. These include handling hydraulic fluid with care to avoid spills and contamination, ensuring that the system is properly pressurized according to manufacturer specifications, and using appropriate personal protective equipment when performing maintenance or repairs. Adhering to these safety practices helps to protect both the operator and the equipment, ensuring safe and effective operation of the hydraulic system .

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins has established a reputation for producing reliable and high-performance components for automotive and industrial applications. The company’s focus on research and development, along with its dedication to customer satisfaction, underscores its position as a leader in the manufacturing of automotive and industrial components.

Cummins Hydraulic Pump Adapter 3939963 Compatibility

The Cummins Hydraulic Pump Adapter part number 3939963 is designed to fit a variety of Cummins engines, ensuring seamless integration and optimal performance. This adapter is crucial for maintaining the hydraulic system’s efficiency and reliability across different engine models.

Compatible Engines

QSB Series

- QSB3.9 30 CM550

- QSB3.9 CM2880 B138

- QSB5.9 30 CM550

- QSB5.9 44 CM550

- QSB5.9 CM2880 B139

The QSB series engines benefit from the 3939963 adapter, which ensures that the hydraulic pump is correctly aligned and securely attached, enhancing the overall hydraulic system performance.

QSC Series

- QSC8.3 CM554

- QSC8.3 CM850 (CM2850)

- QSC9 CM2250/QSL9 CM2250

The QSC series engines also utilize the 3939963 adapter. This part is essential for maintaining the hydraulic pump’s integrity and ensuring that the engine operates smoothly.

QSL Series

- QSL8.9 CM2150 L141

- QSL9 CM2250

- QSL9 CM2350 L102

- QSL9 CM554

- QSL9 CM850 (CM2850)

The QSL series engines are another group that can use the 3939963 adapter. This compatibility ensures that the hydraulic pump is properly connected, contributing to the engine’s efficient operation.

Other Cummins Engines

- 4B3.9

- 6B5.9

- 6C8.3

- B4.5

- B5.9 G

- C8.3 G

- ISB CM550

- ISC CM554

- ISL CM554

The 3939963 adapter is also compatible with a range of other Cummins engines, including the 4B3.9, 6B5.9, 6C8.3, B4.5, B5.9 G, C8.3 G, ISB CM550, ISC CM554, and ISL CM554. This broad compatibility ensures that the adapter can be used across various engine models, providing a versatile solution for hydraulic pump integration.

Role of Part 3939963 Hydraulic Pump Adapter in Engine Systems

The Hydraulic Pump Adapter, identified by part number 3939963, is an essential component in the efficient operation of various engine systems. This adapter facilitates the connection between the hydraulic pump and the front gear train accessory, ensuring seamless power transmission and fluid dynamics within the engine.

Integration with the Drive System

In the drive system, the Hydraulic Pump Adapter acts as a pivotal interface. It securely mounts the hydraulic pump to the engine, allowing for the transfer of mechanical energy from the engine’s rotation to the hydraulic system. This ensures that the hydraulic pump operates in sync with the engine’s performance, providing consistent hydraulic pressure for various engine functions.

Connection to the Front Gear Train Accessory

The front gear train accessory relies on the Hydraulic Pump Adapter to maintain operational integrity. By connecting the hydraulic pump to the front gear train, the adapter ensures that the accessory receives the necessary hydraulic pressure to function effectively. This connection is vital for the smooth operation of the gear train, which in turn influences the overall performance and reliability of the engine.

Role in the Hydraulic Pump Adapter Kit

Within the Hydraulic Pump Adapter Kit, part 3939963 serves as the central component that integrates all elements of the kit. It provides a stable and secure mounting point for the hydraulic pump, ensuring that all connections within the kit are robust and reliable. This integration is essential for the kit’s functionality, as it allows for easy installation and maintenance of the hydraulic system components.

Importance of Proper Mounting

Proper mounting of the Hydraulic Pump Adapter is essential for the longevity and efficiency of the engine system. The adapter must be securely fastened to both the engine and the hydraulic pump to prevent any misalignment or vibration issues. This ensures that the hydraulic system operates within specified parameters, contributing to the engine’s overall performance and durability.

Conclusion

In summary, the Hydraulic Pump Adapter (part 3939963) plays a significant role in the interplay between the drive system, front gear train accessory, and the hydraulic pump adapter kit. Its proper installation and function are key to maintaining the efficiency and reliability of the engine’s hydraulic systems.

-

Quansheng Zhan, Shengbo Eben, Li Kun Deng. Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning, 2018.

↩ -

Angelina Eret. Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature, 2024.

↩ -

R. Matthew Brach. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books, 2023.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4326043, QTR TR101.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.