This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

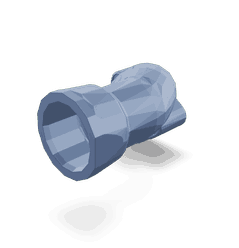

The 4307979 Hydraulic Pump Adapter, manufactured by Cummins, is a component designed to facilitate the operation of hydraulic systems in commercial trucks. Cummins, a well-established name in the automotive industry, produces this adapter to enhance the efficiency and reliability of hydraulic operations in heavy-duty trucks. This part is integral to the smooth functioning of hydraulic systems, which are vital for various truck operations, including braking, steering, and the operation of hydraulic accessories.

Basic Concepts of Hydraulic Pump Adapters

Hydraulic pump adapters serve as intermediary components within hydraulic systems, connecting pumps to other system parts such as hoses, valves, and reservoirs. They play a role in ensuring the proper flow of hydraulic fluid, which is essential for the operation of hydraulic systems. In heavy-duty trucks, these adapters are used in applications ranging from brake systems to power steering and hydraulic lifts, contributing to the overall performance and safety of the vehicle 1.

Purpose of the 4307979 Hydraulic Pump Adapter

The 4307979 is specifically designed to integrate seamlessly with Cummins hydraulic pumps and systems. It facilitates the connection between the pump and other hydraulic components, ensuring a secure and efficient transfer of hydraulic fluid. This Cummins part plays a role in maintaining system pressure and flow, which are critical for the operation of hydraulic systems in trucks. Its design allows for easy installation and compatibility with a range of hydraulic components, enhancing the overall functionality of the truck’s hydraulic system.

Key Features

The 4307979 boasts several key features that contribute to its performance and durability. It is constructed from high-quality materials, ensuring resistance to wear and corrosion. The design includes precision-machined fittings and seals, which play a role in preventing leaks and maintaining system integrity. Additionally, the adapter features a robust construction that can withstand the high pressures and temperatures typical of hydraulic systems in heavy-duty trucks 2.

Benefits

The advantages of using the 4307979 include improved system efficiency and reliability. Its precise design and high-quality materials contribute to reduced maintenance needs and longer component lifespan. For fleet operators, this translates into cost savings over time, as the adapter helps minimize downtime and repair costs associated with hydraulic system failures.

Installation and Integration

Proper installation of the 4307979 is crucial for ensuring its effective operation within a truck’s hydraulic system. Installation guidelines recommend following manufacturer specifications for torque settings and alignment to ensure a secure fit. It may be beneficial to use specialized tools for installation to avoid damage to the adapter or connected components. Integration with existing hydraulic systems requires careful consideration of compatibility and system requirements to ensure optimal performance.

Troubleshooting and Maintenance

Common issues with hydraulic pump adapters can include leaks, connection failures, and wear due to high pressure and temperature. Diagnostic tips for troubleshooting these issues involve checking for proper installation, inspecting seals and fittings for damage, and ensuring compatibility with other system components. Regular maintenance practices, such as cleaning and inspecting the adapter for signs of wear, can help ensure longevity and optimal performance of the hydraulic system 3.

Safety Considerations

When working with the 4307979, it is important to observe safety protocols to prevent injury and ensure the safe operation of the hydraulic system. This includes wearing appropriate personal protective equipment, following manufacturer guidelines for installation and maintenance, and being aware of the high pressures and temperatures involved in hydraulic systems. Proper handling and storage of the adapter are also important to maintain its integrity and performance.

Cummins: Manufacturer Overview

Cummins is a renowned manufacturer in the automotive and heavy-duty truck industry, known for its commitment to quality and innovation. With a history of producing reliable and high-performance components, Cummins has established a strong reputation among fleet operators and automotive professionals. Their focus on research and development ensures that their products, including the 4307979, meet the demanding requirements of commercial truck operations.

Hydraulic Pump Adapter 4307979 Compatibility with Cummins Engines

The Hydraulic Pump Adapter 4307979, manufactured by Cummins, is designed to integrate seamlessly with a range of Cummins engines. This adapter is crucial for ensuring the proper functioning of the hydraulic systems in these engines. Below is a detailed description of its compatibility with specific Cummins engine models.

VTA903 and CM2250 Engines

The Hydraulic Pump Adapter 4307979 is specifically engineered to fit the VTA903 and CM2250 engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The adapter ensures that the hydraulic pump is securely and efficiently connected to the engine, facilitating smooth operation and reducing the risk of leaks or mechanical failures.

V105 Engine

Similarly, the V105 engine is another model that benefits from the use of the Hydraulic Pump Adapter 4307979. This engine is designed for high-performance applications, and the adapter plays a vital role in maintaining the integrity of the hydraulic system. By providing a precise fit, the adapter helps in optimizing the engine’s hydraulic performance, ensuring that it operates at peak efficiency.

Grouping of Engines

While the Hydraulic Pump Adapter 4307979 is compatible with individual engines like the VTA903, CM2250, and V105, it is also worth noting that these engines share common characteristics and design principles. This commonality allows the adapter to be used across these models with ease, providing a standardized solution for hydraulic pump integration in Cummins engines.

Role of Part 4307979 Hydraulic Pump Adapter in Engine Systems

The 4307979 Hydraulic Pump Adapter is an essential component that facilitates the integration of the hydraulic pump within various engine systems. Its primary function is to ensure a secure and efficient connection between the hydraulic pump and other critical components, optimizing the overall performance and reliability of the engine.

Integration with the Pump

When installed, the 4307979 Hydraulic Pump Adapter acts as an intermediary that connects the hydraulic pump to the engine’s power source. This adapter ensures that the pump receives the necessary mechanical input to operate effectively. The adapter’s design allows for precise alignment and mounting, which is vital for the pump’s consistent and smooth operation. This, in turn, enhances the pump’s ability to generate the required hydraulic pressure for various engine functions.

Interaction with Lubricating Oil System

The adapter also plays a significant role in the lubricating oil system. By ensuring a stable connection between the hydraulic pump and the engine, it helps maintain the proper flow of lubricating oil. This is important for reducing friction and wear on moving parts, thereby prolonging the engine’s lifespan. The adapter’s reliable performance contributes to the efficient circulation of lubricating oil, which is essential for the engine’s overall health and efficiency.

Conclusion

In summary, the 4307979 Hydraulic Pump Adapter is a key component that enhances the functionality and durability of engine systems by ensuring seamless integration and operation of the hydraulic pump and lubricating oil system. Its design and features contribute to improved system efficiency, reduced maintenance needs, and overall cost savings for fleet operators.

-

Dixon, J. (2014). Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning.

↩ -

Caines, A. J., Haycock, R. F., & Hillier, J. E. (2004). Automotive Lubricants Reference Book. SAE International.

↩ -

Mollenhauer, K., & Tschoeke, H. (2010). Handbook of Diesel Engines. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.