This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

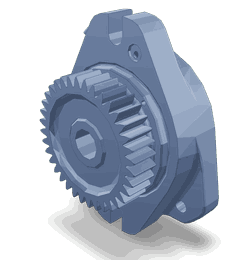

The Cummins Hydraulic Pump Adapter 5526185 is a component designed to enhance the functionality of hydraulic systems in commercial trucks. Cummins, a well-established name in the commercial truck industry, produces a range of parts and systems that contribute to the efficiency and reliability of truck operations. This part plays a role in ensuring the smooth operation of hydraulic systems, which are integral to various truck functions 1.

Basic Concepts of Hydraulic Pump Adapters

Hydraulic systems in trucks are responsible for powering various components such as brakes, steering, and suspension. These systems rely on the transfer of hydraulic fluid to generate the necessary force for operation. Hydraulic pump adapters serve as intermediaries in these systems, facilitating the efficient transfer of hydraulic fluid between different components. They ensure that the hydraulic pump can effectively distribute fluid to where it is needed, maintaining the system’s overall performance 2.

Purpose of the 5526185 Hydraulic Pump Adapter

The 5526185 is designed to connect the hydraulic pump to other components within the truck’s hydraulic system. Its primary function is to ensure a secure and efficient transfer of hydraulic fluid. By doing so, it helps maintain the pressure and flow required for the hydraulic system to operate effectively. This adapter is integral to the system’s ability to perform tasks such as lifting heavy loads, adjusting suspension, and providing braking force 3.

Key Features

This Cummins part is constructed from high-quality materials that ensure durability and reliability. Its design includes precision-machined fittings that allow for a secure connection to both the hydraulic pump and other system components. Additionally, the adapter features corrosion-resistant coatings that enhance its longevity, even in harsh operating environments. These features contribute to the adapter’s ability to perform consistently under demanding conditions 4.

Benefits of Using the 5526185 Hydraulic Pump Adapter

Utilizing the 5526185 offers several advantages. Its robust construction and precise design contribute to improved efficiency within the hydraulic system, ensuring that fluid is transferred with minimal loss or leakage. The adapter’s durability means it can withstand the rigors of commercial truck operations, reducing the need for frequent replacements. Furthermore, its reliable performance enhances the overall reliability of the truck’s hydraulic system, leading to safer and more efficient operations.

Installation Process

Installing the 5526185 requires careful attention to detail to ensure proper functionality. The process involves disconnecting the old adapter, if present, and cleaning the connection points to remove any debris. The new adapter should then be aligned with the hydraulic pump and secured using the appropriate tools. It is important to follow manufacturer guidelines regarding torque specifications to avoid over-tightening, which could damage the adapter or the pump. Safety precautions, such as wearing protective gloves and eyewear, should be observed throughout the installation process.

Common Issues and Troubleshooting

Typical problems that may arise with the 5526185 include fluid leaks, connection failures, and corrosion. Fluid leaks can often be traced to improper installation or worn seals, which may require re-sealing or replacement of the adapter. Connection failures can be addressed by ensuring that all fittings are properly torqued and that there is no cross-threading. Corrosion can be mitigated by regularly inspecting the adapter for signs of wear and applying a corrosion-resistant coating as needed.

Maintenance Tips

Regular maintenance of the 5526185 is key to ensuring its longevity and optimal performance. This includes periodic inspection for signs of wear, corrosion, or fluid leaks. Cleaning the adapter and its connections can prevent buildup that may impede fluid flow. Additionally, ensuring that all connections are properly torqued during routine maintenance checks can help avoid unexpected failures. Following these maintenance practices will contribute to the reliable operation of the truck’s hydraulic system.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the commercial truck industry. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicle operations. Cummins’ commitment to excellence is reflected in its extensive portfolio of high-performance parts, including the 5526185 Hydraulic Pump Adapter.

Cummins Hydraulic Pump Adapter 5526185 Compatibility

The Cummins Hydraulic Pump Adapter part number 5526185 is designed to fit seamlessly with a range of Cummins engines. Specifically, this adapter is compatible with the following engine models:

- F3.8 CM2350 F107

- F4.5 CM2620 F141C

- QSF3.8 CM2350 F107

These engines, while distinct in their specifications, share a commonality in their hydraulic systems, making the 5526185 adapter a versatile component. The adapter’s design ensures a precise fit and optimal performance across these engine types, facilitating efficient hydraulic operation and maintenance.

Conclusion

The 5526185 Hydraulic Pump Adapter by Cummins is a critical component for the efficient operation of hydraulic systems in commercial trucks. Its robust design, precise engineering, and compatibility with various Cummins engines make it a reliable choice for maintaining the performance and reliability of truck hydraulic systems. Regular maintenance and proper installation are key to maximizing the benefits of this part, ensuring safer and more efficient truck operations.

-

Lejda, K., & Wos, P. (2012). Internal Combustion Engines. InTech.

↩ -

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩ -

Schneider, W.-H. (2016). Pistons and Engine Testing. Springer Nature.

↩ -

Goodnight, N., & VanGelder, K. (2019). Automotive Braking Systems CDX Master Automotive Technician Series. Jones Bartlett Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.