This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

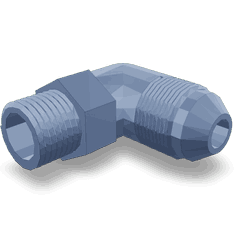

The Male Adapter Elbow 3354938, manufactured by Cummins, is a critical component in the fluid systems of commercial trucks. This adapter elbow facilitates efficient fluid transfer and is essential for the overall functionality of the vehicle.

Basic Concepts of Male Adapter Elbow

A Male Adapter Elbow is a fitting used in fluid systems to connect two pipes at an angle. It features a male thread on one end, which screws into a female fitting, and an angled outlet on the other end. This design allows for a change in direction of the fluid flow, accommodating the complex routing requirements within a truck’s infrastructure. The fitting ensures a secure, leak-proof connection that facilitates the smooth transfer of fluids, such as fuel, coolant, or hydraulic fluid, throughout the system 1.

Purpose of the 3354938 Male Adapter Elbow in Truck Operations

The 3354938 Male Adapter Elbow enables the redirection of fluid flow within the system, which is essential for maintaining the efficiency and reliability of the truck’s operations. By allowing fluids to navigate around obstacles or change direction as needed, this component ensures that the truck’s systems can operate under a variety of conditions without interruption 2.

Key Features

The 3354938 Male Adapter Elbow is constructed from durable materials, ensuring resistance to corrosion and wear. It includes a male thread for secure connection to female fittings and is designed with an angled outlet to facilitate fluid flow redirection. Its design attributes, including precision machining and quality control during manufacturing, contribute to its reliable performance in demanding environments 3.

Benefits of Using the 3354938 Male Adapter Elbow

Utilizing the 3354938 Male Adapter Elbow offers several advantages. Its durable construction ensures long-term reliability, reducing the need for frequent replacements. The design of the fitting allows for ease of installation, minimizing downtime during maintenance procedures. Additionally, its efficiency in fluid systems contributes to the overall performance of the truck, ensuring that fluid transfer occurs smoothly and without leaks 4.

Installation and Integration

Proper installation of the 3354938 Male Adapter Elbow is crucial for ensuring its effectiveness and longevity. Installation procedures involve securely threading the male end into the corresponding female fitting, ensuring a tight seal to prevent leaks. It may be necessary to use tools such as wrenches to achieve the proper torque during installation. Additionally, ensuring that the fitting is compatible with the system’s fluid type and pressure ratings is important for safe and efficient operation.

Maintenance and Troubleshooting

Maintaining the 3354938 Male Adapter Elbow is straightforward but important for ensuring its longevity and optimal performance. Regular inspections for signs of wear, corrosion, or leaks are recommended. Cleaning the fitting and its connections can prevent the buildup of contaminants that may affect performance. Common issues such as leaks can often be resolved by tightening the connection or, if necessary, replacing the fitting. Following manufacturer guidelines for maintenance can help avoid more serious problems.

Safety Considerations

When working with the 3354938 Male Adapter Elbow, observing important safety practices is crucial. This includes wearing appropriate personal protective equipment (PPE) during handling, installation, and maintenance procedures. Ensuring that the system is depressurized before beginning work can prevent injuries from accidental fluid release. Additionally, following proper torque specifications during installation helps prevent over-tightening, which can damage the fitting or the connected components.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s extensive product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicles. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name among fleet operators and maintenance professionals worldwide.

Applications of the 3354938 Male Adapter Elbow in Cummins Engines

The Male Adapter Elbow part 3354938, manufactured by Cummins, is designed to integrate seamlessly with a range of Cummins engines. This part is crucial for ensuring proper fluid flow and connection between various engine components.

For the 4B3.9 and 6B5.9 engines, the Male Adapter Elbow is utilized in the cooling system, facilitating the connection between the engine block and the radiator. Its precision engineering ensures a tight seal, preventing any leaks and maintaining optimal engine temperature.

In the 6C8.3 engine, the Male Adapter Elbow is employed in the exhaust system. It connects the turbocharger to the exhaust manifold, ensuring efficient exhaust gas flow and contributing to the engine’s overall performance and emissions control.

For the QSK19 CM850 MCRS engine, the Male Adapter Elbow is part of the fuel system. It connects the fuel supply lines to the engine, ensuring a steady and reliable fuel flow, which is critical for the engine’s operation and efficiency.

Each of these applications underscores the importance of the Male Adapter Elbow in maintaining the integrity and performance of Cummins engines.

Understanding the Role of Part 3354938 Male Adapter Elbow in Engine Systems

The part 3354938 Male Adapter Elbow is a critical component in various engine systems, facilitating the connection and redirection of fluid or gas flow. Its application is particularly significant in the following areas:

Air Compressor Systems

In air compressor systems, the Male Adapter Elbow is utilized to connect different sections of the air delivery system. It allows for a change in direction of the airflow, which is necessary when routing air from the compressor to various parts of the machinery. This part ensures a secure and leak-free connection, maintaining the efficiency of the air delivery system.

Compressor Mounting Configurations

When mounting compressors, the Male Adapter Elbow plays a role in aligning the compressor with the rest of the system. It provides the necessary angle adjustments to ensure that the compressor is correctly positioned relative to other components. This alignment is vital for the optimal operation of the compressor and the overall system.

Fuel Plumbing Networks

In fuel systems, the Male Adapter Elbow is used to connect fuel lines, allowing for changes in direction without compromising the integrity of the fuel flow. It is particularly useful in complex fuel plumbing setups where space constraints require bends in the fuel lines. The adapter ensures that fuel is delivered efficiently and without leaks, which is essential for the safe and reliable operation of the engine.

Mounting Compressor Air Systems

For systems that involve mounting compressor air components, the Male Adapter Elbow is instrumental in creating a robust and flexible connection. It allows for the adjustment of air lines to accommodate the physical layout of the engine and its components. This flexibility is important for maintaining the performance and durability of the air system.

Conclusion

In summary, the part 3354938 Male Adapter Elbow is a versatile component that enhances the functionality and reliability of engine systems by providing necessary connections and directional changes in fluid or gas flow. Its applications across various engine systems highlight its importance in maintaining the efficiency and performance of commercial trucks.

-

Limpert, Rudolf. Brake Design and Safety, Third Edition. SAE International, 2011.

↩ -

Arora, Shashank, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi. Heavyduty Electric Vehicles: From Concept to Reality. Elsevier, 2021.

↩ -

Martyr, A.J. Engine Testing: Theory and Practice: Third Edition. SAE International, 2007.

↩ -

Bennett, Sean. Modern Diesel Technology Light Duty Diesels. Cengage Learning, 2012.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.