This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

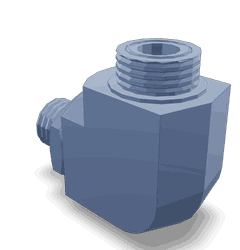

The Male Adapter Elbow 3866217, manufactured by Cummins, is a critical component in the commercial truck industry. This adapter elbow facilitates the connection between various parts of a vehicle’s fluid systems, ensuring efficient fluid routing and system performance.

Basic Concepts of Male Adapter Elbows

A Male Adapter Elbow is a fitting used in fluid systems to change the direction of flow or connect two pipes at an angle. It features a male thread on one end, which screws into a female fitting, and an elbow that allows for a change in direction. These adapters are essential for routing fluids such as fuel, coolant, or hydraulic fluid to their intended destinations within a truck 1.

Purpose of the 3866217 Male Adapter Elbow

The 3866217 Male Adapter Elbow is designed to connect and direct the flow of fluids within a truck’s system. It is used in applications requiring a change in fluid flow direction, ensuring efficient routing to various components. This adapter elbow is part of the system that manages fluid distribution and regulation, contributing to the vehicle’s overall operation and performance 2.

Key Features

This Cummins part is constructed from durable materials resistant to the corrosive effects of the fluids it handles. It features a robust design with precise threading to ensure a secure connection. The adapter elbow is engineered to withstand the pressures and temperatures typical in commercial truck applications, providing reliable performance over time 3.

Benefits

The use of the 3866217 Male Adapter Elbow offers several advantages. It contributes to improved system efficiency by ensuring a smooth and uninterrupted flow of fluids. The design facilitates ease of installation, reducing downtime during maintenance procedures. Additionally, its durable construction and reliable performance minimize the need for frequent replacements, offering maintenance benefits to fleet operators 4.

Installation Considerations

When installing the 3866217 Male Adapter Elbow, it is important to follow best practices to ensure a proper fit and function. This includes using the appropriate tools for tightening connections to the specified torque, verifying the compatibility of the adapter with the system it will be part of, and ensuring that all connections are secure and leak-free. Proper installation is key to the adapter’s performance and the overall efficiency of the fluid system.

Troubleshooting Common Issues

Common issues with Male Adapter Elbows can include leaks at connection points or blockages within the fitting. These problems can often be traced back to improper installation, wear and tear, or compatibility issues. Solutions may involve re-tightening connections, replacing worn-out components, or ensuring that the adapter is correctly matched to the system it serves. Regular inspections can help identify and address these issues before they lead to more significant problems.

Maintenance Tips

To ensure the longevity and reliable performance of the 3866217 Male Adapter Elbow, regular maintenance is recommended. This includes periodic inspections for signs of wear, corrosion, or leaks. Cleaning the adapter and its connections can prevent buildup that might impede fluid flow. Additionally, verifying the tightness of connections during routine maintenance checks can help maintain the integrity of the fluid system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. The company’s extensive product range and commitment to customer satisfaction have made it a preferred choice for fleet operators worldwide.

Compatibility of the Cummins Male Adapter Elbow 3866217

The Cummins Male Adapter Elbow part number 3866217 is designed to fit seamlessly with several engine models, ensuring compatibility and ease of integration. This part is crucial for maintaining the integrity of the engine’s cooling and exhaust systems.

Cummins 6B5.9 and 6C8.3 Engines

The 6B5.9 and 6C8.3 engines are part of Cummins’ lineup of medium-duty diesel engines. The Male Adapter Elbow 3866217 is specifically engineered to fit these engines, providing a secure connection for various fluid lines and components. Its design ensures that it can withstand the operational stresses and temperatures typical of these engines.

Cummins ISB CM550

The ISB CM550 engine is a high-performance, medium-duty diesel engine known for its reliability and efficiency. The Male Adapter Elbow 3866217 is compatible with the ISB CM550, offering a precise fit that enhances the engine’s performance and longevity. This part is essential for maintaining the proper alignment and connection of various system components.

Cummins QSB5.9 44 CM550

The QSB5.9 44 CM550 engine is another robust model in Cummins’ portfolio, designed for heavy-duty applications. The Male Adapter Elbow 3866217 is tailored to fit this engine, ensuring that it can handle the demanding conditions of heavy-duty operations. Its design facilitates smooth fluid flow and secure connections, contributing to the overall efficiency and durability of the engine.

Grouping of Engines

The Cummins Male Adapter Elbow 3866217 is versatile enough to fit into various engine models, including the 6B5.9, 6C8.3, ISB CM550, and QSB5.9 44 CM550. This compatibility across different engine types highlights the part’s universal design and its importance in maintaining the functionality of these engines. Whether used in medium-duty or heavy-duty applications, this adapter elbow ensures that the engine operates at peak efficiency.

Role of Part 3866217 Male Adapter Elbow in Engine Systems

The part 3866217 Male Adapter Elbow is instrumental in facilitating the seamless integration and operation of various engine components. It acts as a pivotal connector, ensuring that the flow of substances such as fuel and oil is maintained efficiently throughout the system.

In the context of the Base Fuel Pump, the Male Adapter Elbow is often used to connect the pump to the fuel lines. This ensures that fuel is delivered consistently from the pump to the engine, supporting combustion and overall engine performance.

When it comes to the Fuel Filter, the Male Adapter Elbow plays a role in linking the filter to the fuel lines. This connection is essential for maintaining the purity of the fuel by allowing contaminants to be filtered out before the fuel reaches the engine.

In systems involving the Full Flow Oil Filter, the Male Adapter Elbow is utilized to connect the filter to the oil passages. This ensures that oil circulates through the filter, removing impurities and maintaining the lubrication quality necessary for engine components.

The Male Adapter Elbow also finds its application in connecting the Fuel Pump to various parts of the fuel system. This connection is vital for maintaining the pressure and flow rate required for efficient fuel delivery to the engine.

Lastly, in scenarios where multiple filters are used, such as a Secondary Fuel Filter or an Additional Oil Filter, the Male Adapter Elbow ensures that these filters are properly integrated into the system. This enhances the filtration process, contributing to the longevity and efficiency of the engine.

Overall, the Male Adapter Elbow is a fundamental component that enhances the functionality and reliability of engine systems by ensuring smooth and uninterrupted flow of essential fluids.

Conclusion

The 3866217 Male Adapter Elbow by Cummins is a vital component in the efficient operation of commercial truck fluid systems. Its robust design, compatibility with various engine models, and role in maintaining fluid flow make it an essential part for fleet operators. Regular maintenance and proper installation are key to ensuring its longevity and performance.

-

Boyce, M. P. (2011). Gas Turbine Engineering Handbook (4th ed.). Butterworth-Heinemann.

↩ -

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩ -

Boyce, M. P. (2002). Gas Turbine Engineering Handbook (2nd ed.). Gulf Professional Publishing.

↩ -

Thompson, R. (2019). Automotive Maintenance: Light Repair. Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.