This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 148476 Adjusting Link is a component designed for use in commercial trucks. It plays a role in the truck’s mechanical system by maintaining proper alignment and tension, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance is fundamental for maintaining and optimizing the performance of commercial trucks.

Function and Operation

The Cummins 148476 Adjusting Link operates within the truck’s mechanical system to maintain proper alignment and tension. It is integral to ensuring that various components work in harmony, which is vital for the smooth operation of the vehicle. By adjusting the link, mechanics can fine-tune the mechanical system to meet specific operational requirements, thereby enhancing the truck’s performance and longevity 1.

Key Features

The Cummins 148476 Adjusting Link is characterized by several key features that contribute to its effectiveness. It is constructed from durable materials, ensuring it can withstand the rigors of commercial truck use. The design incorporates elements that allow for easy adjustment and integration within the truck’s mechanical system. Additionally, it may feature unique characteristics that enhance its functionality and ease of use 2.

Benefits of Using the Adjusting Link

Incorporating the Cummins 148476 Adjusting Link into a truck’s mechanical system offers several advantages. It contributes to improved performance by ensuring components are properly aligned and tensioned. The link’s durable construction enhances the truck’s reliability, while its design facilitates easier maintenance, reducing downtime and operational costs 3.

Installation Process

Installing the Cummins 148476 Adjusting Link requires a systematic approach to ensure it is correctly integrated into the truck’s mechanical system. The process involves identifying the correct position for the link, using the appropriate tools for installation, and following safety precautions to protect both the installer and the vehicle. Detailed instructions should be followed to achieve a secure and effective installation.

Maintenance Tips

Regular maintenance of the Cummins 148476 Adjusting Link is crucial for ensuring its longevity and optimal performance. This includes periodic checks for wear and tear, ensuring it remains properly aligned and tensioned, and cleaning it to prevent the accumulation of debris that could affect its operation. Adhering to these maintenance practices can significantly extend the life of the link and enhance the truck’s overall performance.

Troubleshooting Common Issues

Common issues associated with the Cummins 148476 Adjusting Link may include misalignment, tension problems, or wear and tear. Troubleshooting these issues involves identifying the symptoms, such as unusual noises or decreased performance, and taking corrective actions. This may include realigning the link, adjusting its tension, or replacing it if it is worn out.

Safety Considerations

When working with the Cummins 148476 Adjusting Link, it is important to observe safety guidelines and precautions. This includes ensuring the truck is properly secured before beginning work, using the correct tools and equipment, and following all safety protocols to prevent accidents or injuries. Handling and installation safety are paramount to protect both the mechanic and the vehicle.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history of innovation and a commitment to quality, Cummins serves customers in approximately 190 countries and territories through a network of company-owned and independent distributor facilities and dealerships. The company’s product range includes engines, filtration, emissions solutions, and related technologies, all designed to meet the needs of commercial truck operators and other industries.

Role of Part 148476 Adjusting Link in Engine Systems

Part 148476, the Adjusting Link, is integral to the proper functioning of several components within engine systems. Its primary role is to facilitate precise adjustments and maintain optimal alignment and tension in various mechanical assemblies.

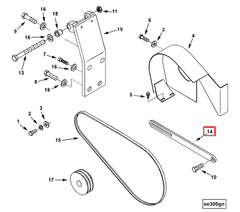

Alternator Mounting

In alternator mounting systems, the Adjusting Link ensures that the alternator is securely and correctly positioned. This is essential for the alternator to function efficiently, generating the necessary electrical power for the vehicle’s systems. Proper alignment and tension provided by the Adjusting Link prevent undue stress on the alternator and its mounting bracket, enhancing durability and performance.

Alternator Mounting Bracket

The alternator mounting bracket relies on the Adjusting Link to maintain the correct spacing and alignment between the alternator and the engine. This ensures that the alternator operates within its designed parameters, reducing the risk of mechanical failures and improving the overall efficiency of the electrical system. The Adjusting Link allows for fine-tuning of the bracket’s position, accommodating variations in engine design and installation requirements.

Mounting Alternator

When mounting the alternator, the Adjusting Link plays a key role in achieving the right balance of tension and alignment. It enables technicians to make necessary adjustments during installation, ensuring that the alternator is neither too tight nor too loose. This precision is vital for the alternator’s longevity and the consistent performance of the vehicle’s electrical system. The Adjusting Link simplifies the mounting process, allowing for quick and accurate adjustments that enhance installation efficiency.

Conclusion

The Cummins 148476 Adjusting Link is a critical component in the maintenance and optimization of commercial trucks. Its role in ensuring proper alignment and tension within the mechanical system contributes to the vehicle’s efficiency, reliability, and longevity. Regular maintenance, proper installation, and adherence to safety guidelines are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.