This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3250867 Adjusting Link is a component designed for use in the suspension systems of commercial trucks. Its role is to facilitate the adjustment of suspension settings, which is vital for maintaining optimal performance and stability of the vehicle under various load conditions 2.

Purpose and Function

The 3250867 Adjusting Link serves a specific function within the suspension system by allowing for the fine-tuning of suspension geometry. This adjustment capability ensures that the truck maintains proper alignment and balance, which contributes to the overall performance and stability of the vehicle 3. By enabling precise adjustments, the link helps in achieving the desired ride height and handling characteristics, which are important for both safety and efficiency in commercial operations.

Key Features

The design of the 3250867 Adjusting Link incorporates several features that enhance its durability and functionality. Constructed from high-strength materials, it is built to withstand the rigors of heavy-duty use. The link’s design allows for easy adjustment, which can be performed with standard tools, facilitating maintenance and repair processes. Additionally, its robust construction ensures longevity, reducing the frequency of replacements and associated downtime 4.

Benefits

Utilizing the 3250867 Adjusting Link offers several advantages. It contributes to improved load handling by ensuring that the suspension system can adapt to varying weights and road conditions. This adaptability enhances ride comfort for both the driver and any passengers, as well as for the cargo being transported. Furthermore, the link’s design and construction contribute to the increased longevity of suspension components, reducing the overall maintenance costs and enhancing the vehicle’s reliability 1.

Installation Process

Proper installation of the 3250867 Adjusting Link is crucial for ensuring optimal performance. The process involves several steps, starting with the preparation of the suspension system for the new component. This includes ensuring that all mating surfaces are clean and free from debris. The link should be installed according to the manufacturer’s specifications, with attention paid to torque settings and alignment. Correct installation is paramount to achieving the desired suspension performance and safety 2.

Maintenance and Troubleshooting

Regular maintenance of the 3250867 Adjusting Link is recommended to ensure continued reliable operation. This includes periodic inspections for signs of wear or damage, as well as ensuring that all fasteners remain tight. Common issues that may arise include misalignment or wear on the link itself, which can often be addressed through readjustment or replacement of worn components. Proactive maintenance can prevent more serious issues from developing, ensuring the longevity and performance of the suspension system 3.

Safety Considerations

When handling and using the 3250867 Adjusting Link, it is important to follow safety guidelines to protect both the operator and the vehicle. This includes wearing appropriate personal protective equipment during installation and maintenance procedures. Regular inspections of the link and associated components are necessary to identify any potential issues before they lead to safety concerns. Replacement of the link should be considered if any significant wear or damage is observed, to maintain the safety standards of the vehicle 4.

Cummins Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its commitment to quality and innovation in automotive components. With a history of providing reliable and high-performance parts, Cummins has built a reputation for excellence. The company’s dedication to advancing technology and improving the efficiency and reliability of commercial vehicles is evident in its wide range of products, including the 3250867 Adjusting Link.

Cummins Adjusting Link Part 3250867 Compatibility

The Cummins Adjusting Link part number 3250867 is designed to fit seamlessly within the engine configurations of the N14 MECHANICAL and NH/NT 855 engines.

For the N14 MECHANICAL engine, the adjusting link plays a pivotal role in the engine’s mechanical linkage system. It ensures that the engine’s components are properly aligned and that the mechanical functions are executed smoothly. This part is integral to maintaining the precision and reliability of the engine’s performance.

In the NH/NT 855 engine, the adjusting link is equally essential. It is part of the engine’s linkage system that controls various mechanical functions. The NH/NT 855 engine, known for its robust design and efficiency, relies on the precise operation of components like the adjusting link to maintain optimal performance and longevity.

Both engines benefit from the use of the Cummins Adjusting Link part number 3250867, as it ensures that the mechanical linkages are correctly adjusted, which is crucial for the overall functionality and efficiency of the engine.

Role of Part 3250867 Adjusting Link in Engine Systems

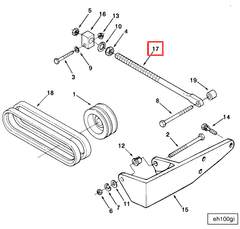

Part 3250867, the Adjusting Link, is integral to the precise alignment and operation of several key components within engine systems. Its primary function is to facilitate the correct positioning and tensioning of the alternator and its associated mounting structures.

Alternator and Mounting Components

The Adjusting Link works in conjunction with the alternator and its mounting components to ensure optimal performance. It interfaces with the alternator mounting bracket and the alternator itself, allowing for fine adjustments that are essential for maintaining the correct belt tension. This, in turn, ensures that the alternator operates efficiently, providing a stable electrical supply to the engine’s systems.

Base Parts and Structural Integrity

In the context of base parts, the Adjusting Link plays a supportive role by helping to secure the alternator in place. This is particularly important for the structural integrity of the engine assembly, as it prevents undue stress on the alternator mounting points and the alternator bracket. Proper alignment facilitated by the Adjusting Link reduces the risk of component wear and failure.

EBM: Location and System Integration

When considering the EBM (Engine Bay Module) location, the Adjusting Link ensures that the alternator is correctly positioned within the confined space of the engine bay. This is vital for the integration of the alternator into the overall engine system, allowing for efficient operation without interference from adjacent components.

Alternator Mounting and Operational Efficiency

The alternator mounting process benefits significantly from the Adjusting Link. By providing the necessary adjustments, it allows mechanics to fine-tune the alternator’s position, which is essential for operational efficiency. This adjustment capability is particularly important during maintenance or replacement procedures, ensuring that the alternator functions correctly within the engine system.

Summary of Component Interaction

In summary, Part 3250867 Adjusting Link is a key component in the interaction between the alternator, alternator bracket, and mounting structures. Its role in facilitating precise adjustments ensures that these components work harmoniously, contributing to the overall efficiency and reliability of the engine system.

Conclusion

The Cummins 3250867 Adjusting Link is a critical component in both the suspension systems of commercial trucks and the engine systems of specific Cummins engines. Its design and functionality contribute to the optimal performance, stability, and reliability of these vehicles. Proper installation, regular maintenance, and adherence to safety guidelines are essential for maximizing the benefits of this Cummins part.

-

Quigley, Jon M. SAE International’s Dictionary of Testing, Verification and Validation. SAE International, 2023.

↩ -

Viskup, Richard. Diesel and Gasoline Engines. IntechOpen, 2020.

↩ ↩ -

Norman, Andrew. Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc, 2016.

↩ ↩ -

Pulkrabek, Willard W. Engineering Fundamentals of the Internal Combustion Engine. Pearson Education, 2014.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.