This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

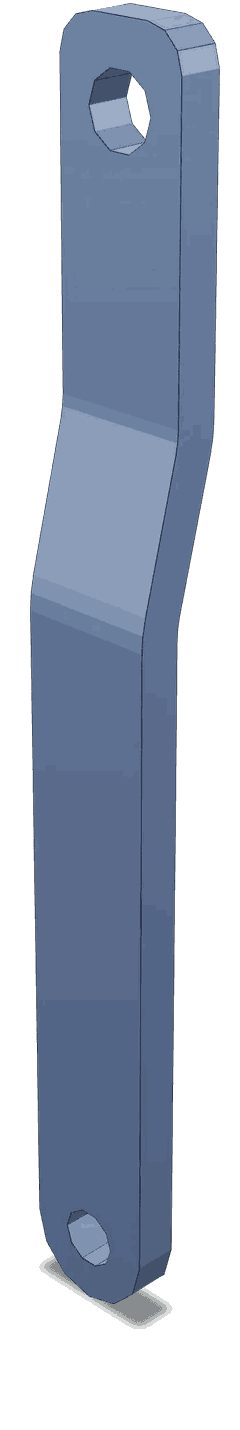

The Cummins 3102149 Adjusting Link is a component designed for use in the suspension systems of commercial trucks. Its purpose is to facilitate the proper alignment and performance of the truck’s suspension, ensuring that the vehicle operates efficiently and safely under various conditions.

Function and Operation

This part functions within the truck’s suspension system by connecting different components, allowing for adjustments that maintain the alignment of the suspension. This link plays a role in absorbing shocks and vibrations from the road, which helps in maintaining the truck’s stability and handling characteristics. Proper alignment facilitated by the Adjusting Link ensures that the truck’s tires make consistent contact with the road, which is vital for optimal performance and longevity of the vehicle 1.

Key Features

This Cummins part is constructed from durable materials, typically high-strength steel, to withstand the rigors of commercial truck operations. Its design includes precision-machined ends for secure attachment to other suspension components. Additionally, the link may feature protective coatings to resist corrosion and wear, enhancing its durability in various operating environments.

Benefits

The use of the 3102149 Adjusting Link offers several benefits. It contributes to improved handling by ensuring that the suspension system remains properly aligned. This alignment enhances the truck’s stability, particularly when navigating turns or uneven terrain. Furthermore, by maintaining optimal suspension performance, the Adjusting Link helps reduce wear on other components, potentially extending the lifespan of the truck’s suspension system.

Installation Process

Installing this part requires careful attention to ensure proper function and safety. The process involves disconnecting the old link, if present, and attaching the new link using the appropriate tools and equipment. It is important to follow manufacturer guidelines for torque specifications and alignment settings to ensure the link is installed correctly 2.

Maintenance and Troubleshooting

Regular maintenance of the 3102149 Adjusting Link is crucial for ensuring optimal performance. This includes periodic inspections for signs of wear or damage, and ensuring that all connections are secure and properly torqued. Common issues may include misalignment or wear on the link, which can be addressed by realigning the suspension or replacing the link as necessary.

Performance Impact

The 3102149 Adjusting Link plays a role in the overall performance of the truck by contributing to ride quality, load-carrying capacity, and durability. Proper alignment and suspension performance facilitated by the Adjusting Link can lead to a smoother ride, better handling under load, and increased durability of the truck’s suspension components.

Safety Considerations

When handling, installing, or maintaining the 3102149 Adjusting Link, it is important to adhere to safety practices. This includes using the appropriate personal protective equipment, ensuring the truck is securely supported during installation, and following all manufacturer guidelines to prevent accidents or injuries.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history dating back to 1919, Cummins has established itself as a key player in the commercial truck industry, providing reliable and innovative solutions to meet the demands of various applications 3.

Role of Part 3102149 Adjusting Link in Engine Systems

The 3102149 Adjusting Link is a component in the synchronization and fine-tuning of various engine systems. Its primary function is to facilitate precise adjustments that ensure optimal performance and efficiency of interconnected components.

Interaction with Mounting Systems

In engine systems, the mounting structure is vital for securing components in place while allowing for necessary movements and vibrations. This part plays a significant role here by providing the needed flexibility and adjustability. It allows engineers and mechanics to fine-tune the tension and alignment of mounted components, ensuring that they operate within specified tolerances. This adjustability is particularly important in high-vibration environments, where even minor misalignments can lead to increased wear and reduced efficiency.

Coordination with Alternator

The alternator is a key component responsible for generating electrical power to charge the battery and power the vehicle’s electrical systems. The 3102149 Adjusting Link assists in maintaining the proper belt tension for the alternator drive system. Accurate tension is essential for efficient power transfer from the engine to the alternator. If the belt is too loose, it may slip, leading to insufficient power generation. Conversely, if it is too tight, it can cause excessive wear on both the belt and the alternator components. The Adjusting Link enables precise adjustments to achieve the optimal belt tension, ensuring reliable and efficient operation of the alternator.

Enhanced System Integration

Beyond individual components, the 3102149 Adjusting Link contributes to the overall integration of engine systems. By allowing for micro-adjustments, it helps in aligning multiple components such as pulleys, brackets, and other ancillary parts. This ensures that all elements work in harmony, reducing the likelihood of mechanical failures and enhancing the engine’s longevity.

Conclusion

In summary, the 3102149 Adjusting Link is a versatile component that enhances the functionality and reliability of engine systems by providing the necessary adjustability for mounting structures and drive systems, such as the alternator. Its role in fine-tuning these components ensures that the engine operates smoothly and efficiently.

-

Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles, Andrew Brown Jr, National Academy of Sciences, 2010

↩ -

The History and Impact of Diesel Engines and Gas Turbines, Vaclav Smil, The MIT Press, 2010

↩ -

General Information, Bulletin Number 4021557, Operation and Maintenance Manual

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.