This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

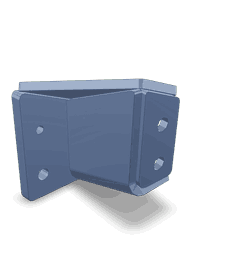

The Cummins Aftercooler Bracket, part number 5367457, is a component designed to support the aftercooler within the engine system of heavy-duty trucks. Its role is to securely hold the aftercooler in place, ensuring it functions effectively as part of the engine’s cooling system.

Purpose and Function

The Aftercooler Bracket plays a role in the truck’s engine system by supporting the aftercooler, which is responsible for cooling the compressed air from the turbocharger before it enters the engine’s combustion chambers 1. This cooling process enhances engine efficiency by reducing the temperature of the intake air, which in turn improves combustion efficiency and reduces thermal stress on engine components 3.

Key Features

This Cummins part is constructed from high-strength materials, ensuring durability and resistance to the harsh conditions encountered in heavy-duty truck operations. It features precise mounting points that allow for secure attachment of the aftercooler, minimizing vibrations and ensuring stable operation. The design incorporates features that facilitate easy installation and maintenance, contributing to the overall reliability of the engine system.

Benefits

The use of the Aftercooler Bracket offers several advantages. It contributes to improved engine efficiency by ensuring the aftercooler remains in optimal position and condition. This results in more effective cooling of the intake air, which can lead to enhanced engine performance and reduced wear on engine components. Additionally, the bracket’s robust construction and secure mounting help to maintain the overall reliability of the truck’s engine system.

Installation and Compatibility

Proper installation of the Aftercooler Bracket is important for ensuring its effectiveness and the efficiency of the engine system. Installation procedures should follow manufacturer guidelines to ensure compatibility with the specific truck model and engine configuration. Attention to detail during installation helps to prevent issues such as misalignment or insecure mounting, which could affect the performance of the aftercooler and, by extension, the engine.

Maintenance and Troubleshooting

Routine maintenance of the Aftercooler Bracket involves inspecting it for signs of wear or damage, ensuring that all mounting points are secure, and verifying that the aftercooler is properly aligned. Regular checks can help identify potential issues before they lead to more significant problems. Troubleshooting common issues may involve tightening loose mounting bolts, replacing worn components, or addressing any signs of corrosion or damage to the bracket or aftercooler.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the automotive industry, Cummins is known for its commitment to quality and innovation in commercial vehicle components. The company’s extensive experience and dedication to excellence are reflected in its wide range of products, including the Aftercooler Bracket, which is designed to meet the demanding requirements of heavy-duty truck applications 2.

Role of Part 5367457 Aftercooler Bracket in Turbocharger Arrangement

The Aftercooler Bracket, identified by part number 5367457, plays a role in the turbocharger arrangement of an engine system. This bracket supports the aftercooler, which is a heat exchanger that cools the compressed air from the turbocharger before it enters the engine’s intake manifold.

Integration with Turbocharger

In the turbocharger arrangement, the Aftercooler Bracket is positioned to support the aftercooler in a manner that ensures optimal airflow and thermal efficiency. The turbocharger compresses the intake air, which increases its temperature. The aftercooler, mounted using the Aftercooler Bracket, cools this air, enhancing its density and allowing the engine to burn fuel more efficiently 3.

Connection to Intake Manifold

The Aftercooler Bracket also facilitates the connection between the aftercooler and the intake manifold. By providing a stable mounting point, it ensures that the aftercooler is aligned correctly with the intake manifold, allowing for a smooth transition of cooled air into the engine cylinders.

Support for Intercooler Piping

In systems that incorporate intercooler piping, the Aftercooler Bracket supports these pipes by maintaining the structural integrity of the aftercooler assembly. This support is vital for the durability and performance of the intercooler system, which further cools the air before it reaches the intake manifold.

Role in Engine Bay Layout

From an engine bay layout perspective, the Aftercooler Bracket helps in organizing the space efficiently. It ensures that the aftercooler is positioned in a way that does not interfere with other components, such as the turbocharger, exhaust manifold, or engine accessories. This organized layout is important for maintaining easy access for maintenance and repairs.

Contribution to Overall System Performance

By securely mounting the aftercooler, the Aftercooler Bracket contributes to the overall performance and reliability of the turbocharger arrangement. It ensures that the aftercooler operates within its designed parameters, thereby supporting the engine’s power output and fuel efficiency.

Conclusion

The Cummins Aftercooler Bracket, part number 5367457, is a vital component in the engine systems of heavy-duty trucks. It ensures the effective operation of the aftercooler, contributing to enhanced engine efficiency, performance, and reliability. Proper installation, maintenance, and understanding of its role in the turbocharger arrangement are key to maximizing the benefits of this part.

-

Genta, G., & Morello, L. (2019). The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer.

↩ -

Smil, V. (2010). The History and Impact of Diesel Engines and Gas Turbines. The MIT Press.

↩ -

Lakshminarayanan, P. A., & Aghav, Y. V. (2010). Modelling Diesel Combustion. Springer Science.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.