This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

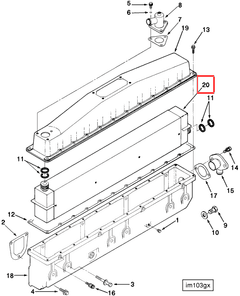

The Cummins 3411460 Aftercooler Core is a component designed for use in heavy-duty trucks. It serves a specific function within the engine’s cooling system, contributing to the overall efficiency and performance of the vehicle. Understanding its purpose and operation is key to maintaining and optimizing the performance of heavy-duty trucks.

Basic Concepts of Aftercooler Cores

An aftercooler core is a heat exchanger used in the engine cooling system of turbocharged engines. Its function is to cool the compressed air from the turbocharger before it enters the engine’s combustion chambers. By reducing the temperature of the air, the aftercooler core increases the air density, which in turn enhances the engine’s efficiency and power output. Additionally, cooling the air helps to reduce the formation of deposits and prolongs the life of engine components 1.

Purpose of the Cummins 3411460 Aftercooler Core

The Cummins 3411460 Aftercooler Core is specifically engineered to cool the compressed air from the turbocharger in heavy-duty trucks. This cooling process is vital as it prepares the air for optimal combustion within the engine. By ensuring that the air entering the engine is at the correct temperature, the aftercooler core plays a role in maintaining engine efficiency and performance, contributing to the truck’s overall reliability and durability.

Key Features

The Cummins 3411460 Aftercooler Core is characterized by its robust design and the quality materials used in its construction. It features a compact yet efficient core structure that maximizes heat exchange. The materials chosen for its construction are selected for their durability and resistance to corrosion, ensuring long-term performance in demanding environments. Additionally, the design of the aftercooler core allows for easy integration into the truck’s engine system, facilitating straightforward installation and maintenance.

Benefits of Using the Cummins 3411460 Aftercooler Core

Incorporating the Cummins 3411460 Aftercooler Core into a heavy-duty truck’s engine system offers several advantages. It contributes to improved engine efficiency by ensuring that the air entering the combustion chambers is at an optimal temperature. This enhancement in efficiency can lead to better fuel economy and reduced emissions. Furthermore, the durable construction of the aftercooler core means it can withstand the rigors of heavy-duty use, potentially offering cost savings over time through extended component life and reduced maintenance requirements 2.

Installation and Integration

Proper installation of the Cummins 3411460 Aftercooler Core is crucial for ensuring its effective operation within the truck’s engine system. Installation should be carried out according to the manufacturer’s guidelines, which may include specific preparations or considerations to ensure compatibility and optimal performance. Careful attention to the integration process helps to avoid common installation pitfalls and ensures the aftercooler core functions as intended.

Maintenance and Care

To ensure the Cummins 3411460 Aftercooler Core continues to perform at its best, regular maintenance is recommended. This includes periodic inspections for signs of wear or damage, cleaning to remove any contaminants that may affect performance, and adhering to recommended replacement schedules. Proper maintenance not only helps to maintain the efficiency of the aftercooler core but also contributes to the overall reliability of the truck’s engine system.

Troubleshooting Common Issues

Common issues associated with aftercooler cores, such as leaks or reduced efficiency, can often be traced back to installation errors, contamination, or wear and tear. Troubleshooting these problems effectively involves a systematic approach to identifying the root cause, whether it be a faulty seal, blockage within the core, or external damage. Addressing these issues promptly can help to restore the aftercooler core’s performance and prevent more serious engine problems.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and history of excellence make it a trusted name among professionals in the heavy-duty truck sector.

Role of Part 3411460 Aftercooler Core in Engine Systems

The Aftercooler Core (Part 3411460) is an integral component within various engine systems, enhancing performance and efficiency through its interaction with several key components.

Interaction with Aftercooler Components

-

Aftercooler: The Aftercooler Core is the heart of the aftercooler system, responsible for cooling the compressed air from the turbocharger before it enters the engine. This cooling process increases air density, allowing for more efficient combustion.

-

Aftercooler Kit: When integrated into an aftercooler kit, the core works in conjunction with other components such as hoses, fittings, and sensors to ensure optimal cooling and performance.

-

Aftercooler Water Plumbing: The core interfaces with the water plumbing system to facilitate the transfer of heat from the air to the cooling water, enhancing the overall efficiency of the aftercooling process.

Air Management Systems

-

Air Aftercooler: In air-to-air aftercoolers, the core plays a vital role in dissipating heat from the compressed air, improving engine efficiency and power output.

-

Air Assembly Intercooler: The core is a critical element in the air assembly intercooler, where it ensures that the air entering the engine is at the optimal temperature for combustion.

-

Air Intake Intercooler: Positioned within the air intake system, the core helps in pre-cooling the intake air, which is essential for maintaining engine performance under various operating conditions.

-

Air Intake Manifold: The cooled air from the aftercooler core is directed into the air intake manifold, where it mixes with fuel before entering the combustion chambers.

Manifold and Turbocharger Systems

-

Air Intake Manifold: The core’s efficient cooling allows for denser air to enter the intake manifold, leading to better fuel combustion and increased engine power.

-

Air Manifold: In systems with complex air manifolds, the aftercooler core ensures uniform air temperature distribution, which is crucial for consistent engine performance.

-

Turbocharger Arrangement: The core works in tandem with the turbocharger, ensuring that the air entering the engine is cooled post-compression, which is essential for preventing detonation and improving engine longevity.

Mounting and Structural Components

-

Air Intercooler Mounting: The core is securely mounted within the intercooler housing, ensuring stability and efficient heat exchange.

-

Air Mounting Intercooler: Proper mounting of the core within the intercooler is essential for maintaining the structural integrity and performance of the aftercooling system.

Turbo and EBM Location

- EBM: Location, Turbo: The core’s placement in relation to the turbocharger (EBM: location, turbo) is designed to optimize the cooling process immediately after air compression, ensuring the air is at the ideal temperature before entering the engine.

Conclusion

In summary, the Aftercooler Core (Part 3411460) is a fundamental component that enhances the efficiency and performance of various engine systems by ensuring that the air entering the engine is cooled to the optimal temperature. Its integration into the engine system contributes to improved engine efficiency, better fuel economy, reduced emissions, and overall reliability of the heavy-duty truck.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.