This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

This article provides an overview of the Cummins Aftercooler Seal Kit 4933305. It covers the basic concepts, purpose, key features, benefits, and maintenance suggestions related to this component. The Aftercooler Seal Kit is designed for use in commercial trucks and plays a role in maintaining the efficiency and performance of the aftercooling system.

Basic Concepts

An aftercooler is a device used in turbocharged engines to cool the compressed air before it enters the engine’s combustion chambers. The Aftercooler Seal Kit is a set of components that ensures the integrity of the aftercooling system by preventing air leaks and maintaining proper pressure levels 2.

Purpose of the Aftercooler Seal Kit

The primary purpose of the Aftercooler Seal Kit 4933305 is to maintain the efficiency of the aftercooling process. By sealing the connections within the aftercooler system, it helps ensure that cooled air is delivered to the engine without loss of pressure or introduction of contaminants, which can affect engine performance and longevity 3.

Key Features

The Aftercooler Seal Kit 4933305 includes various seals and gaskets designed to fit specific connections within the aftercooler system. These components are made from durable materials that can withstand high pressures and temperatures, ensuring long-lasting performance. The kit is engineered to be compatible with Cummins engines, providing a precise fit and effective sealing 1.

Benefits

Using the Aftercooler Seal Kit 4933305 offers several benefits, including improved engine efficiency due to effective air cooling, reduced risk of engine damage from contaminants, and enhanced overall performance of the turbocharged system. Proper sealing also contributes to fuel efficiency and can extend the lifespan of the engine by maintaining optimal operating conditions 2.

Troubleshooting and Maintenance

Regular inspection of the aftercooler system is recommended to identify any signs of wear or damage to the seals. Common issues include leaks, which can be detected by checking for unusual noises or a drop in engine performance. Maintenance involves ensuring that all connections are tight and that the seals are in good condition. Replacement of the Aftercooler Seal Kit should be performed according to the manufacturer’s guidelines to ensure continued efficiency and performance 3.

Compatibility with Cummins Engines

The Cummins Aftercooler Seal Kit part number 4933305 is designed to fit a range of Cummins diesel engines, ensuring optimal performance and reliability. This seal kit is specifically engineered to provide a secure and effective seal for the aftercooler, which is a critical component in the engine’s cooling system.

6B5.9 Engine

The 6B5.9 engine is a robust and reliable power unit, often used in various industrial and agricultural applications. The Aftercooler Seal Kit 4933305 is compatible with this engine, ensuring that the aftercooler operates efficiently and maintains the necessary pressure to enhance engine performance.

QSB5.9 CM850 and QSB6.7 M CM2250 Engines

The QSB5.9 CM850 and QSB6.7 M CM2250 engines are part of Cummins’ QSB series, known for their durability and power. These engines are commonly used in a variety of applications, including construction equipment, generators, and marine vessels. The Aftercooler Seal Kit 4933305 is designed to fit these engines, providing a critical seal that helps maintain the integrity of the aftercooling system. This ensures that the engine operates at peak efficiency, reducing the risk of overheating and extending the lifespan of the engine.

Role of the Aftercooler Seal Kit in Engine Systems

The Aftercooler Seal Kit 4933305 is an essential component that ensures the efficient operation of various engine systems by maintaining the integrity of the aftercooler assembly.

Integration with Aftercooler

The Aftercooler Seal Kit is designed to create a secure seal between the aftercooler and its connecting components. This seal is vital for preventing leaks of compressed air, which can lead to a loss of efficiency and potential damage to the engine system.

Function in Aftercooler Conversion Kit

When an engine is upgraded with an Aftercooler Conversion Kit, the Aftercooler Seal Kit plays a significant role in ensuring that the new aftercooler is properly sealed to the existing engine components. This is important for maximizing the performance gains offered by the conversion kit.

Interaction with Aftercooler Core

The Aftercooler Core is the heart of the aftercooler system, responsible for cooling the compressed air before it enters the engine. The Aftercooler Seal Kit ensures that the core is tightly sealed, preventing any bypass of air that has not been properly cooled. This maintains the efficiency of the aftercooler and protects the engine from damage due to overly hot air.

Role in Aftercooler Kit

An Aftercooler Kit typically includes various components designed to enhance the cooling of compressed air. The Aftercooler Seal Kit is a fundamental part of this kit, ensuring that all components work together seamlessly without air leaks. This contributes to the overall effectiveness of the aftercooler system.

Arrangement with Turbocharger

In engine systems equipped with a Turbocharger, the aftercooler is often placed after the turbocharger to cool the compressed air before it enters the engine. The Aftercooler Seal Kit ensures that the connection between the turbocharger and the aftercooler is leak-free, which is essential for maintaining the turbocharger’s efficiency and longevity.

Conclusion

By understanding the role of the Aftercooler Seal Kit 4933305 in these components, engineers and mechanics can better appreciate its importance in maintaining the performance and reliability of engine systems.

-

Bennett, S. (2012). Modern Diesel Technology: Light Duty Diesels. Cengage Learning.

↩ -

Wright, G. (2015). Fundamentals of Medium-Heavy Duty Diesel Engines. Jones & Bartlett Learning.

↩ ↩ -

Brach, R. M. (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books.

↩ ↩

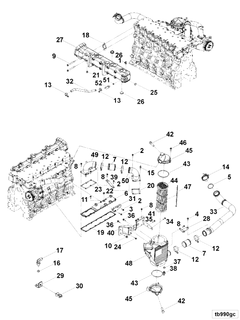

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.