This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

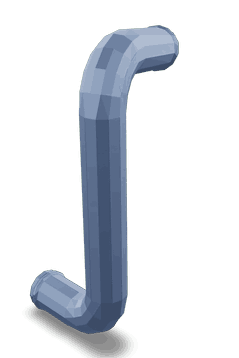

The 3401062 Aftercooler Tube, manufactured by Cummins, is a vital component in the engine systems of heavy-duty trucks. This part is designed to enhance the efficiency and performance of the engine by cooling the compressed air from the turbocharger before it enters the engine cylinders 1.

Basic Concepts of Aftercooler Tubes

Aftercooler tubes are part of the engine’s air cooling system, designed to cool the compressed air from the turbocharger. This process is essential as it increases the air’s density, leading to more efficient combustion within the engine cylinders and improved engine performance and efficiency 2.

Purpose of the 3401062 Aftercooler Tube

The 3401062 is engineered to facilitate the cooling of compressed air in heavy-duty trucks. By lowering the air temperature before it enters the engine cylinders, this tube enhances engine performance and reduces thermal stress on engine components, contributing to the engine’s durability and reliability 3.

Key Features

This Cummins part is characterized by its robust design and the use of high-quality materials, ensuring durability and efficient performance. Its design maximizes the cooling efficiency of the compressed air, and the materials used are selected for their ability to withstand high temperatures and pressures within the engine system.

Benefits

Utilizing the 3401062 in a truck’s engine system offers several benefits. It contributes to improved engine efficiency by ensuring that the air entering the engine cylinders is at an optimal temperature for combustion. This results in enhanced engine performance and reduced thermal stress on engine components. Additionally, the efficient operation of the aftercooler tube can lead to better overall performance of the truck.

Installation and Integration

Proper installation of the 3401062 is crucial for its optimal performance within the truck’s engine system. It should be integrated according to the manufacturer’s guidelines to ensure that it functions correctly and efficiently. Correct installation ensures the tube’s effectiveness in cooling the compressed air and contributes to the overall performance and reliability of the engine.

Troubleshooting and Maintenance

Common issues with aftercooler tubes may include leaks, blockages, or damage to the tube itself. Regular inspections and maintenance are important to identify and address these issues promptly. Maintenance tips include checking for signs of wear or damage, ensuring there are no leaks in the system, and cleaning or replacing the tube as necessary. Regular maintenance helps in ensuring the longevity and efficient operation of the 3401062.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer of diesel engines and related technologies, with a history of innovation and commitment to quality in the automotive industry. The company’s products, including the 3401062, are designed with a focus on enhancing engine performance, efficiency, and durability. Cummins’ dedication to quality and innovation has established it as a trusted name in the manufacturing of diesel engines and components.

Role of the 3401062 Aftercooler Tube in Engine Systems

The Aftercooler Tube, identified by part number 3401062, is an integral component in the efficient operation of engine systems that incorporate aftercooling technology. This component is specifically designed to facilitate the transfer of coolant between the aftercooler and other parts of the engine system.

Integration with Plumbing Systems

In engine systems, the Aftercooler Tube works in conjunction with the plumbing network to ensure a seamless flow of coolant. The plumbing system, which includes hoses, pipes, and fittings, relies on the Aftercooler Tube to maintain consistent coolant levels and pressure. This integration helps in dissipating heat effectively, which is essential for the longevity and performance of the engine.

Function within the Aftercooler Water Circuit

The Aftercooler Tube plays a significant role in the aftercooler water circuit. This circuit is responsible for cooling the compressed air from the turbocharger before it enters the engine’s combustion chamber. The Aftercooler Tube ensures that the coolant is circulated efficiently, maintaining optimal temperatures and preventing overheating. This not only enhances engine performance but also contributes to fuel efficiency and reduced emissions.

Enhancing System Reliability

By ensuring a reliable connection between the aftercooler and the rest of the engine’s cooling system, the Aftercooler Tube helps in maintaining system integrity. It prevents leaks and ensures that the coolant is distributed evenly, which is vital for the consistent operation of the engine. This reliability is particularly important in high-stress environments where engine performance is paramount.

Supporting Overall Engine Efficiency

The efficient operation of the Aftercooler Tube directly impacts the overall efficiency of the engine. By maintaining proper coolant flow, it helps in reducing the thermal load on the engine components. This, in turn, allows the engine to operate more efficiently, with lower wear and tear on critical parts. The Aftercooler Tube, therefore, is a key component in the quest for enhanced engine performance and durability.

Conclusion

The 3401062 Aftercooler Tube by Cummins is a critical component in the engine systems of heavy-duty trucks. Its role in cooling the compressed air from the turbocharger enhances engine performance, efficiency, and durability. Proper installation, regular maintenance, and understanding its function within the engine system are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.