This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

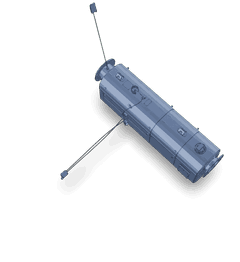

The Cummins 4353993 Aftertreatment Device is a component designed to enhance the emissions control system of heavy-duty trucks. Its role is significant in the broader context of reducing the environmental impact of diesel engines, aligning with stringent emissions regulations.

Basic Concepts of Aftertreatment Devices

Aftertreatment devices are systems designed to reduce the emissions produced by internal combustion engines. They are integrated into the exhaust system of heavy-duty trucks to filter out pollutants before they are released into the atmosphere. These devices work by converting harmful emissions into less harmful substances through various chemical and physical processes 1.

Purpose of the Cummins 4353993 Aftertreatment Device

The Cummins 4353993 Aftertreatment Device is specifically engineered to reduce the emissions output of heavy-duty trucks. It plays a role in the emissions control system by facilitating the conversion of nitrogen oxides (NOx) and particulate matter into less harmful components. This device helps trucks meet environmental regulations by ensuring that emissions are within permissible limits.

Key Features

The Cummins 4353993 Aftertreatment Device is characterized by its robust design and the use of high-quality materials that ensure durability and efficiency. It incorporates advanced technological features that enhance its performance, such as precise engineering to optimize the conversion of emissions and integration with the truck’s electronic control system for real-time adjustments.

Benefits

The advantages of the Cummins 4353993 Aftertreatment Device include improved emissions performance, which contributes to a reduction in the environmental footprint of heavy-duty trucks. Additionally, it may offer potential fuel efficiency gains by optimizing the engine’s operation 2. Compliance with regulatory standards is another benefit, ensuring that trucks equipped with this device meet current and future emissions regulations.

Installation and Integration

Installation of the Cummins 4353993 Aftertreatment Device involves integrating it into the truck’s exhaust system. This process requires adherence to specific guidelines to ensure proper fitment and function. Considerations for installation include the device’s compatibility with the truck’s engine and exhaust system, as well as any necessary modifications to the existing system.

Operation and Functionality

The Cummins 4353993 Aftertreatment Device operates through a combination of sensors, control systems, and maintenance protocols. It works in conjunction with the truck’s engine management system to monitor and adjust the aftertreatment process in real time. Regular maintenance is required to ensure the device’s optimal performance, including checks on sensors and the overall condition of the device.

Troubleshooting and Maintenance

Common issues with the Cummins 4353993 Aftertreatment Device may include sensor malfunctions or efficiency reductions over time. Diagnostic procedures involve checking the device’s sensors and control systems for proper operation. Maintenance practices include regular inspections, cleaning, and replacement of components as needed to ensure the device continues to function effectively.

Environmental Impact

The Cummins 4353993 Aftertreatment Device contributes to environmental protection by significantly reducing harmful emissions from heavy-duty trucks. Its operation leads to a decrease in pollutants such as NOx and particulate matter, which are known to have adverse effects on air quality and human health. This reduction in emissions plays a part in improving overall air quality.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation in diesel engine technology, Cummins is committed to developing solutions that enhance engine performance while reducing environmental impact. The company’s expertise in emissions control is evident in its range of aftertreatment devices, including the Cummins 4353993, which are designed to meet the challenges of modern emissions regulations.

Compatibility

This Cummins part is designed to integrate seamlessly with a range of Cummins engines, ensuring optimal performance and compliance with emissions standards. It is specifically engineered to fit within the engine architecture of the QSK50 and CM2350 series, providing essential functions such as exhaust gas treatment and emissions control.

For the QSK50 engine, the 4353993 Aftertreatment Device is a critical component that interfaces with the engine’s exhaust system. It is engineered to work in conjunction with the engine’s control systems to manage and reduce harmful emissions, ensuring the engine operates within regulatory limits.

In the case of the CM2350 engine, the 4353993 Aftertreatment Device is similarly integrated into the exhaust system. This part is designed to handle the specific exhaust requirements of the CM2350, ensuring efficient and effective emissions control. The device’s design allows it to be easily installed and maintained, providing long-term reliability and performance.

The K108 engine, while not explicitly mentioned in the provided list, also benefits from the 4353993 Aftertreatment Device. This part is compatible with the K108’s exhaust system, ensuring that the engine meets stringent emissions standards. The device’s integration with the K108 is seamless, providing the necessary functions to manage exhaust gases and reduce environmental impact.

Overall, the Cummins Aftertreatment Device 4353993 is a versatile and essential component for the QSK50, CM2350, and K108 engines, ensuring that these engines operate efficiently and within regulatory requirements.

Role of Aftertreatment Device (Part 4353993) in Engine Systems

The aftertreatment device, specifically part 4353993, is integral to the operation of modern engine systems. It works in conjunction with several key components to ensure efficient and environmentally compliant engine performance.

Integration with the Exhaust System

The aftertreatment device is positioned downstream of the engine’s exhaust manifold. Its primary function is to process the exhaust gases before they are released into the atmosphere. This involves reducing harmful emissions such as nitrogen oxides (NOx), particulate matter (PM), and hydrocarbons (HC).

Interaction with the Diesel Particulate Filter (DPF)

In diesel engine systems, the aftertreatment device often includes a Diesel Particulate Filter (DPF). The DPF captures soot and other particulates from the exhaust stream. The aftertreatment device monitors and regulates the DPF’s regeneration process, ensuring that accumulated particulates are effectively burned off without damaging the filter.

Coordination with the Selective Catalytic Reduction (SCR) System

For engines equipped with a Selective Catalytic Reduction (SCR) system, the aftertreatment device plays a significant role. It manages the injection of urea (DEF) into the exhaust stream, where it reacts with NOx to form harmless nitrogen and water vapor. The aftertreatment device ensures precise dosing and monitoring of the urea, optimizing the reduction process.

Communication with the Engine Control Unit (ECU)

The aftertreatment device communicates continuously with the Engine Control Unit (ECU). This communication allows for real-time adjustments to the engine’s operation based on the condition of the aftertreatment components. For instance, if the DPF requires regeneration, the ECU can adjust the engine’s fuel injection timing and quantity to facilitate the process.

Synergy with Oxygen Sensors

Oxygen sensors placed before and after the aftertreatment device provide critical data on the exhaust gas composition. The device uses this information to fine-tune the air-fuel mixture and ensure that the catalytic processes within the aftertreatment system are operating at peak efficiency.

Role in Thermal Management

The aftertreatment device also contributes to the thermal management of the exhaust system. By controlling the temperature of the exhaust gases, it helps maintain the optimal operating conditions for the DPF and SCR system, thereby prolonging their lifespan and ensuring consistent performance.

Conclusion

In summary, the aftertreatment device (part 4353993) is a sophisticated component that enhances the functionality and environmental compliance of engine systems through its interaction with various other components.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.