This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

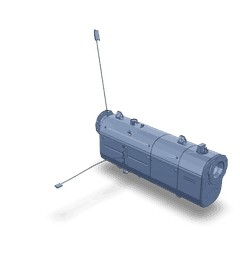

The Cummins 4358100 Aftertreatment Device is a component designed to enhance the environmental performance of commercial trucks. It plays a role in reducing emissions and ensuring compliance with environmental regulations, which is increasingly important in the context of commercial truck operations 1.

Basic Concepts of Aftertreatment Devices

Aftertreatment devices are systems installed in the exhaust path of diesel engines to reduce the levels of pollutants emitted into the atmosphere. These devices work by converting harmful emissions into less harmful substances through chemical reactions. They contribute significantly to emissions reduction, helping vehicles meet stringent environmental standards 2.

Purpose of the 4358100 Aftertreatment Device

The Cummins 4358100 Aftertreatment Device is specifically designed to play a role in the emissions control system of a truck. It functions by processing exhaust gases to reduce the levels of nitrogen oxides (NOx) and particulate matter (PM). This device helps trucks comply with environmental regulations by ensuring that emissions are within acceptable limits 3.

Key Features

The 4358100 Aftertreatment Device incorporates several key features that enhance its performance. Its design includes advanced materials and technological innovations that improve its efficiency and durability. These features contribute to its ability to effectively reduce emissions and maintain compliance with regulatory standards 4.

Benefits

The advantages provided by the 4358100 Aftertreatment Device include improved emissions performance, which is crucial for meeting environmental regulations. Additionally, it may contribute to potential fuel efficiency gains by optimizing the exhaust system’s operation. Compliance with regulatory standards is another significant benefit, ensuring that trucks operate within legal limits 5.

Installation and Integration

Proper installation and integration of the 4358100 Aftertreatment Device within a truck’s exhaust system are important for its effective operation. Guidelines and considerations for installation include ensuring compatibility with the truck’s existing exhaust system and following manufacturer recommendations to achieve optimal performance 6.

Operational Efficiency

The 4358100 Aftertreatment Device operates under various driving conditions, adapting to changes in engine load and speed. Its impact on overall truck performance includes maintaining efficient emissions control without compromising engine power or fuel efficiency. This ensures that the truck continues to operate smoothly and effectively 7.

Troubleshooting and Maintenance

Common issues that may arise with the 4358100 Aftertreatment Device include sensor malfunctions and blockages within the device. Diagnostic procedures involve checking for error codes and performing physical inspections. Maintenance practices to ensure optimal performance and longevity include regular cleaning and inspection of the device and its components 8.

Regulatory Compliance

The 4358100 Aftertreatment Device plays a role in helping trucks meet emissions regulations. Adherence to these standards is important for environmental protection and legal compliance. The device ensures that trucks emit pollutants at levels that are within the limits set by regulatory bodies 9.

Cummins Corporation

Cummins Corporation is a leading manufacturer of diesel engines and related technologies, including aftertreatment devices. With a history of innovation and commitment to environmental responsibility, Cummins plays a role in developing advanced diesel technologies that contribute to cleaner and more efficient vehicle operations 10.

Cummins Aftertreatment Device 4358100 Compatibility

The Cummins Aftertreatment Device 4358100 is designed to integrate seamlessly with a range of Cummins engines, ensuring optimal performance and compliance with stringent emissions standards. This part is specifically engineered to fit within the engine architecture of the QSK50, CM2350, and K108 engines, providing a reliable solution for exhaust treatment.

QSK50

The QSK50 engine, known for its robust performance and efficiency, is well-suited for heavy-duty applications. The Aftertreatment Device 4358100 is engineered to fit into the QSK50’s exhaust system, ensuring that emissions are effectively managed and regulated. This compatibility is crucial for maintaining the engine’s performance while adhering to environmental regulations.

CM2350

The CM2350 engine, a member of Cummins’ mid-range power series, benefits from the integration of the Aftertreatment Device 4358100. This part is designed to fit into the CM2350’s exhaust system, providing a seamless connection that ensures efficient exhaust treatment. The compatibility of this device with the CM2350 engine is essential for achieving the desired balance between performance and emissions control.

K108

The K108 engine, part of Cummins’ lineup of smaller, yet powerful engines, is also compatible with the Aftertreatment Device 4358100. This part is engineered to fit into the K108’s exhaust system, ensuring that emissions are effectively managed. The integration of this device with the K108 engine is critical for maintaining the engine’s performance while meeting environmental standards.

By ensuring compatibility with these engines, the Cummins Aftertreatment Device 4358100 provides a reliable solution for exhaust treatment, enhancing the overall performance and efficiency of the engines.

Role of Aftertreatment Device (Part 4358100) in Engine Systems

The aftertreatment device, specifically part 4358100, is integral to the operation and efficiency of modern engine systems. This component works in conjunction with several other engine components to ensure optimal performance and compliance with emissions standards.

Integration with the Exhaust System

The aftertreatment device is positioned within the exhaust system, downstream of the turbocharger and the exhaust manifold. Its primary function is to treat the exhaust gases before they are released into the atmosphere. This involves reducing harmful emissions such as nitrogen oxides (NOx), particulate matter (PM), and hydrocarbons (HC).

Interaction with the Diesel Particulate Filter (DPF)

One of the key components the aftertreatment device interacts with is the Diesel Particulate Filter (DPF). The DPF captures soot and other particulates from the exhaust gases. The aftertreatment device aids in the regeneration process of the DPF by ensuring that the exhaust gases maintain the necessary temperature and composition for effective regeneration.

Coordination with the Selective Catalytic Reduction (SCR) System

The aftertreatment device also plays a significant role in the Selective Catalytic Reduction (SCR) system. It ensures that the exhaust gases are properly conditioned before they pass through the SCR catalyst. This conditioning involves precise control of the exhaust temperature and the introduction of urea (DEF) into the exhaust stream. The aftertreatment device helps in the efficient conversion of NOx into harmless nitrogen (N2) and water (H2O).

Synergy with the Exhaust Gas Recirculation (EGR) System

In engines equipped with an Exhaust Gas Recirculation (EGR) system, the aftertreatment device works to manage the recirculated exhaust gases. It helps in reducing the overall temperature of the exhaust, which is essential for the proper functioning of downstream components like the DPF and SCR. This temperature management is vital for preventing thermal damage and ensuring the longevity of these components.

Enhancement of Overall Engine Efficiency

By effectively treating the exhaust gases, the aftertreatment device contributes to the overall efficiency of the engine. It ensures that the engine operates within the desired emissions parameters, which can lead to improved fuel economy and reduced maintenance costs. Additionally, it helps in maintaining the engine’s performance over time by preventing the buildup of harmful deposits and reducing the risk of component failure.

Conclusion

In summary, the aftertreatment device (part 4358100) is a vital component that enhances the functionality and efficiency of modern engine systems. Its interaction with the exhaust system, DPF, SCR system, and EGR system ensures that the engine operates cleanly and efficiently, meeting both performance and environmental standards.

-

Automotive Braking Systems CDX Master Automotive Technician Series, Nicholas Goodnight and Kirk VanGelder, Jones Bartlett Learning, 2019

↩ -

Modern Diesel Technology: Heavy Equipment Systems, Robert Huzij, Angelo Spano, Sean Bennett, Cengage Learning, 2019

↩ -

SAE International’s Dictionary for Automotive Engineers, John F Kershaw, SAE International, 2023

↩ -

Engine: QSB3.9 CM2880 B138, Bulletin Number: 5411052, Owners Manual

↩ -

Automotive Braking Systems CDX Master Automotive Technician Series, Nicholas Goodnight and Kirk VanGelder, Jones Bartlett Learning, 2019

↩ -

Modern Diesel Technology: Heavy Equipment Systems, Robert Huzij, Angelo Spano, Sean Bennett, Cengage Learning, 2019

↩ -

SAE International’s Dictionary for Automotive Engineers, John F Kershaw, SAE International, 2023

↩ -

Engine: QSB3.9 CM2880 B138, Bulletin Number: 5411052, Owners Manual

↩ -

Automotive Braking Systems CDX Master Automotive Technician Series, Nicholas Goodnight and Kirk VanGelder, Jones Bartlett Learning, 2019

↩ -

SAE International’s Dictionary for Automotive Engineers, John F Kershaw, SAE International, 2023

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.