This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

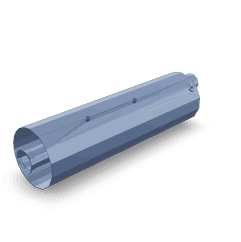

The Cummins 5258762 Aftertreatment Device is designed to manage and reduce emissions in heavy-duty trucks, ensuring that exhaust gases meet regulatory standards. This device is integral to emissions control, minimizing the environmental impact of heavy-duty vehicles.

Basic Concepts of Aftertreatment Devices

Aftertreatment devices are systems installed in the exhaust path of internal combustion engines to reduce harmful pollutants. These devices convert or capture pollutants such as nitrogen oxides (NOx), particulate matter (PM), and hydrocarbons (HC) into less harmful substances. They integrate into the engine system by processing exhaust gases post-combustion before release into the atmosphere 1.

Function and Operation of the 5258762 Aftertreatment Device

The Cummins 5258762 Aftertreatment Device operates through chemical and physical processes to reduce emissions. It includes a Diesel Oxidation Catalyst (DOC), a Diesel Particulate Filter (DPF), and a Selective Catalytic Reduction (SCR) system. The DOC converts carbon monoxide and hydrocarbons into carbon dioxide and water. The DPF captures particulate matter from the exhaust. The SCR system uses a urea-based solution to convert NOx into nitrogen and water 2.

Key Features of the 5258762 Aftertreatment Device

The primary features of the 5258762 Aftertreatment Device include its robust design, built to withstand heavy-duty truck operation. It utilizes high-quality materials for durability and efficiency. Technological innovations within the device enhance its performance, such as advanced catalyst formulations and precise control algorithms for the SCR system 3.

Role in Truck Operation

This Cummins part ensures that the engine’s exhaust emissions comply with environmental regulations. It contributes to engine performance by maintaining efficient exhaust flow and reducing backpressure. Additionally, it can impact fuel efficiency by optimizing the combustion process and reducing the need for excessive fuel consumption to meet emissions standards.

Benefits of Using the 5258762 Aftertreatment Device

The use of this part offers several benefits. It helps achieve improved emissions compliance, crucial for operating in regions with strict environmental regulations. It may also lead to potential cost savings by reducing the risk of fines and penalties associated with non-compliance. Furthermore, it can enhance engine longevity by maintaining optimal operating conditions and reducing the stress on engine components due to excessive emissions control measures.

Troubleshooting Common Issues

Common issues with the 5258762 Aftertreatment Device may include clogging of the DPF, malfunctions in the SCR system, or sensor failures. Diagnostic tips include monitoring exhaust temperature and pressure, checking for error codes, and ensuring the urea solution is properly maintained. Recommended solutions may involve cleaning or replacing the DPF, recalibrating the SCR system, or replacing faulty sensors.

Maintenance Recommendations

To ensure optimal performance and longevity of the 5258762 Aftertreatment Device, regular maintenance is recommended. This includes inspecting the device at specified intervals, cleaning or replacing the DPF as needed, and ensuring the SCR system is functioning correctly. Additionally, maintaining the urea solution reservoir and monitoring sensor readings are important practices.

Environmental Impact

The Cummins 5258762 Aftertreatment Device contributes to reduced emissions by effectively capturing and converting pollutants into less harmful substances. This helps in compliance with environmental regulations and reduces the overall environmental footprint of heavy-duty trucks. The device plays a role in promoting cleaner air and mitigating the effects of air pollution.

Cummins Corporation Overview

Cummins Corporation is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and aftertreatment systems. With a history of innovation and a commitment to sustainability, Cummins has established itself as a leader in the field of engine technology and emissions control. The company’s product range includes solutions for on-highway, off-highway, and stationary applications, all aimed at providing reliable and efficient power while minimizing environmental impact.

Cummins Aftertreatment Device 5258762 Compatibility

The Cummins Aftertreatment Device part number 5258762 is designed to integrate seamlessly with a range of Cummins engines, ensuring optimal performance and compliance with emissions regulations. This part is specifically engineered to fit the following engines:

- ISB/ISD4.5 CM2150 B119

- ISB/ISD4.5 CM2150 B119

These engines are known for their robust performance and reliability, making them a popular choice in various applications. The aftertreatment device is crucial for reducing harmful emissions, ensuring that the engines operate within environmental standards. The compatibility of the part with these engines is a testament to Cummins’ commitment to providing high-quality, reliable components that enhance engine performance and efficiency.

Role of Part 5258762 Aftertreatment Device in Engine Systems

The Part 5258762 Aftertreatment Device is an integral component within the aftertreatment system of modern engine configurations. Its primary function is to ensure that exhaust emissions meet regulatory standards by reducing harmful pollutants.

When the exhaust gases exit the engine, they pass through the turbocharger, where energy is recovered to improve engine efficiency. Post-turbocharging, the gases enter the Diesel Oxidation Catalyst (DOC), which begins the process of converting harmful carbon monoxide (CO) and hydrocarbons (HC) into less harmful carbon dioxide (CO2) and water (H2O).

Following the DOC, the exhaust stream moves into the Diesel Particulate Filter (DPF), where soot and particulate matter are trapped. The Part 5258762 Aftertreatment Device plays a supportive role here by aiding in the regeneration process of the DPF, ensuring that accumulated particulates are effectively burned off.

Next, the Selective Catalytic Reduction (SCR) system comes into play. The Aftertreatment Device interacts with the SCR by helping to maintain optimal conditions for the reduction of nitrogen oxides (NOx) into nitrogen (N2) and water vapor. This is achieved through the injection of Diesel Exhaust Fluid (DEF), which reacts with the NOx in the presence of a catalyst.

Throughout this process, the Aftertreatment Device monitors and regulates various parameters such as temperature, pressure, and the concentration of emissions. It communicates with the Engine Control Unit (ECU) to adjust the operation of components like the Exhaust Gas Recirculation (EGR) valve, ensuring that the engine operates within permissible emission limits while maintaining performance and fuel efficiency.

In summary, the Part 5258762 Aftertreatment Device is a key player in the orchestration of the aftertreatment system, working in concert with other components to clean exhaust emissions and comply with environmental regulations.

Conclusion

The Cummins 5258762 Aftertreatment Device is a critical component in the effort to reduce emissions from heavy-duty trucks. By integrating advanced technologies and robust design, this part ensures that engines comply with stringent environmental regulations while maintaining performance and efficiency. Regular maintenance and proper troubleshooting are essential to maximize the benefits of this device, contributing to a cleaner environment and sustainable operation of heavy-duty vehicles.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.