This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

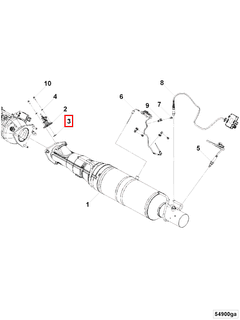

The Cummins Aftertreatment System Gasket 5311323 is a specialized component designed for use in heavy-duty trucks. Its purpose is to ensure the effective operation of the aftertreatment system by providing a reliable seal between various system components. This gasket plays a role in maintaining the integrity of the aftertreatment system, which is vital for the overall performance and emissions control of the truck 1.

Basic Concepts of Aftertreatment Systems

Aftertreatment systems are designed to reduce harmful emissions from diesel engines. These systems typically include components such as diesel particulate filters (DPFs), selective catalytic reduction (SCR) systems, and diesel oxidation catalysts (DOCs). They work by capturing and converting pollutants into less harmful substances before they are released into the atmosphere. The integration of aftertreatment systems into the engine system of a truck is crucial for meeting environmental regulations and minimizing the truck’s environmental impact 2.

Role of the Aftertreatment System Gasket

The Aftertreatment System Gasket 5311323 plays a specific role within the aftertreatment system by providing a seal between components. This seal is important for maintaining system integrity and ensuring that exhaust gases flow through the system as intended. By preventing leaks, the gasket helps to maintain the efficiency of the aftertreatment processes, which are designed to reduce emissions and improve air quality 3.

Key Features of the 5311323 Gasket

The 5311323 Gasket is characterized by several key features that enhance its effectiveness. These include its material composition, which is designed to withstand high temperatures and pressures, and its precise design specifications that ensure a proper fit within the aftertreatment system. Additionally, the gasket may have unique attributes such as enhanced flexibility or resistance to chemical corrosion, which contribute to its performance and durability.

Benefits of Using the 5311323 Gasket

Using the 5311323 Gasket offers several advantages. It provides improved sealing efficiency, which helps to maintain the performance of the aftertreatment system. The gasket’s durability ensures that it can withstand the demanding conditions within the exhaust system, contributing to the overall longevity of the system. Additionally, by ensuring a reliable seal, the gasket plays a role in enhancing the system’s performance and reducing the likelihood of emissions-related issues.

Installation and Maintenance

Proper installation of the 5311323 Gasket is important for ensuring its effectiveness. This involves following manufacturer guidelines to ensure that the gasket is correctly positioned and that all system components are properly aligned. Regular maintenance practices, such as inspecting the gasket for signs of wear or damage and replacing it as needed, are recommended to ensure optimal performance and longevity of the aftertreatment system.

Troubleshooting Common Issues

Common problems associated with aftertreatment system gaskets can include leaks, which may result from improper installation, wear, or damage. Identifying these issues early is important for maintaining system efficiency. Recommended troubleshooting steps include inspecting the gasket for signs of damage, ensuring that all system components are properly aligned, and replacing the gasket if necessary to restore system integrity.

Regulatory Compliance and Emissions Reduction

The 5311323 Gasket contributes to meeting regulatory standards for emissions by ensuring the effective operation of the aftertreatment system. By maintaining a reliable seal, the gasket plays a role in ensuring that the system functions as intended, which is important for complying with environmental regulations and reducing the truck’s environmental impact 4.

Cummins: A Brief Overview

Cummins Inc. is a leader in the design, manufacture, and distribution of diesel and alternative fuel engines, as well as related technologies. With a history of innovation and a commitment to quality, Cummins has established itself as a trusted provider of diesel engine technology. The company’s expertise in engine systems and components, including aftertreatment systems, underscores its role in advancing the performance and efficiency of heavy-duty trucks.

Compatibility with ISV Engines

The Cummins Aftertreatment System Gasket 5311323 is designed to ensure a secure seal in the aftertreatment system of various engines, including the ISV (Intelligent Systems Vehicle) engines produced by Nissan. This gasket is specifically engineered to fit seamlessly with these engines, ensuring optimal performance and reliability. Its compatibility with ISV engines is a result of precise engineering and rigorous testing, providing a robust seal that prevents leaks and maintains system pressure.

Role of the 5311323 Aftertreatment System Gasket in Engine Systems

The 5311323 Aftertreatment System Gasket is an essential component in ensuring the proper functioning of various engine systems, particularly those related to emissions control. This gasket plays a significant role in the integration and sealing of multiple components within the aftertreatment system.

Integration with Aftertreatment Device

The aftertreatment device, commonly known as the Diesel Particulate Filter (DPF) or Selective Catalytic Reduction (SCR) system, relies on precise sealing to maintain efficiency. The 5311323 Aftertreatment System Gasket ensures that the connections between the aftertreatment device and the exhaust system are airtight. This sealing prevents exhaust leaks, which can compromise the performance of the aftertreatment device and lead to increased emissions.

Sealing the Aftertreatment System

Within the aftertreatment system, various components work in unison to reduce harmful emissions. The gasket ensures that the interfaces between these components—such as the DPF, SCR catalyst, and dosing module—are securely sealed. This prevents the escape of exhaust gases and maintains the integrity of the system, allowing for optimal chemical reactions necessary for emission reduction.

Connection to Doser Injector

The doser injector, which introduces Diesel Exhaust Fluid (DEF) into the exhaust stream, must be precisely fitted to the aftertreatment system. The 5311323 Aftertreatment System Gasket facilitates a tight seal around the doser injector, ensuring that DEF is effectively atomized and mixed with the exhaust gases. This sealing is vital for the urea-SCR process, which converts nitrogen oxides (NOx) into harmless nitrogen and water.

Ensuring System Efficiency

By providing a reliable seal, the 5311323 Aftertreatment System Gasket contributes to the overall efficiency of the aftertreatment system. It helps maintain the correct pressure and temperature conditions required for the chemical reactions within the SCR and DPF systems. This, in turn, ensures that the engine meets emissions standards and operates within regulatory limits.

Conclusion

In summary, the 5311323 Aftertreatment System Gasket is a fundamental component that enhances the performance and reliability of the aftertreatment system by ensuring secure and leak-free connections between critical components. Its role in maintaining system integrity, ensuring efficient emissions control, and contributing to regulatory compliance underscores its importance in the operation of heavy-duty trucks.

-

Brown Jr, Andrew. Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences, 2010.

↩ -

Xin, Qianfan. Diesel Engine System Design. Woodhead Publishing, 2011.

↩ -

Taghavifar, Hamid, and Aref Mardani. Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer, 2017.

↩ -

Eret, Angelina. Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature, 2024.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.